Casting equipment and casting method for light alloy motor shell

A technology for motor housings and casting equipment, which is applied in casting equipment, metal processing equipment, equipment for handling molds, etc., and can solve the problems of not being tight enough to fix molds, affecting casting effects, and reducing practicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

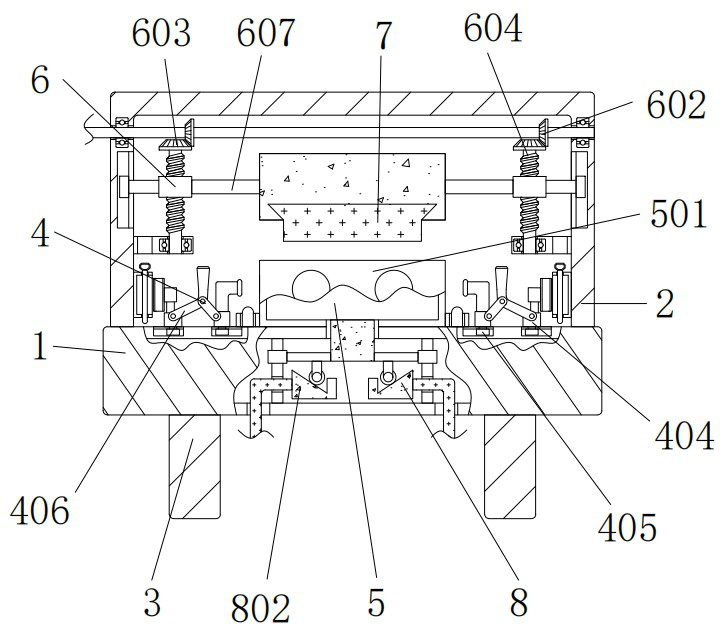

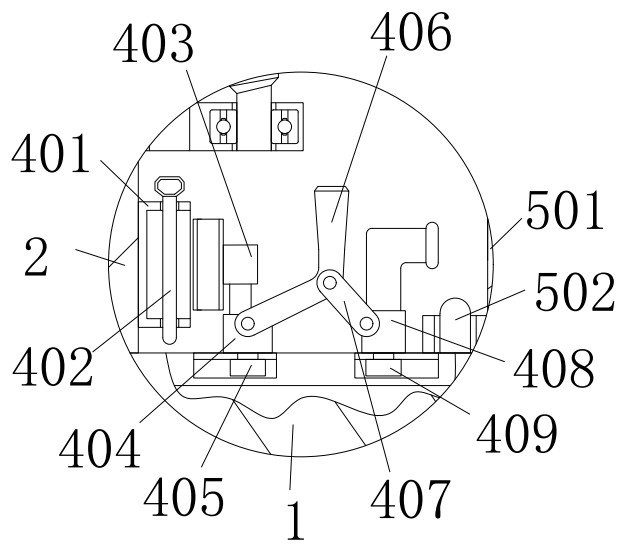

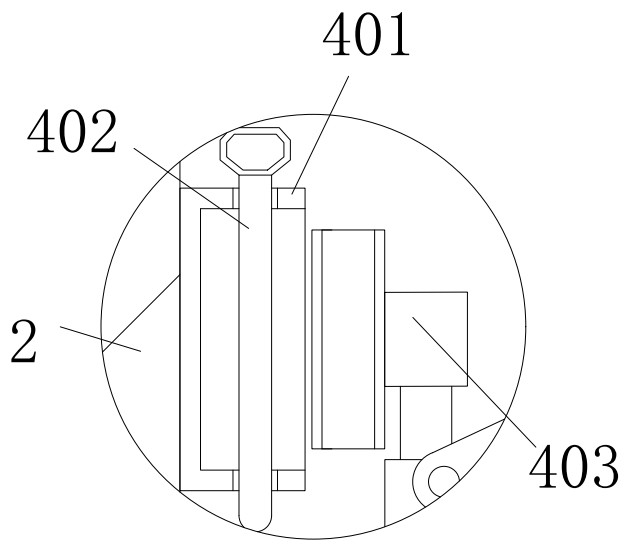

[0034] A casting equipment for light alloy motor casings, comprising a first casing 1, a second casing 2 and a strut 3, the top of the first casing 1 is communicated with a second casing 2, and the The left and right sides of the bottom are fixed with pillars 3. There are four pillars 3 distributed in parallel at the bottom of the first shell 1. The top left and right sides of the first shell 1 are provided with fixing devices 4. The fixing devices 4 include squares. Shell 401, plug 402, vertical cylinder 403, first block 404, first slider 405, curved plate 406, inclined plate 407, second block 408 and second slider 409, the left side of the square shell 401 and the second shell The left side of the inner wall of the body 2 is fixedly connected, the through holes on the upper and lower sides of the square shell 401 are gap-fitted with a plug pin 402, the right side of the plug pin 402 is provided with a vertical cylinder 403, and the plug pin 402 can be inserted in the through ...

Embodiment 2

[0036] As an optional case, see figure 1 , 5And 6, used for light alloy motor shell casting equipment, the first shell 1 is provided with a demoulding device 8 inside, and the demoulding device 8 includes a bent rod 801, a trapezoidal block 802, a thin rod 803, a sliding sleeve 804, a sliding The rod 805 and the thick plate 806, the left side of the outer wall of the bent rod 801 is in clearance fit with the bottom left groove of the first shell 1, the bent rod 801 can move in the bottom left groove of the first shell 1, the bent rod A trapezoidal block 802 is fixed on the upper right side of the 801. A thin rod 803 is attached to the top of the trapezoidal block 802. A sliding sleeve 804 is fixed on the top of the thin rod 803. The upper and lower ends of the rod 805 are fixedly connected to the upper and lower sides of the inner wall of the first housing 1 respectively, and the lower through hole of the outer wall of the sliding rod 805 is in clearance fit with the outer wa...

Embodiment 3

[0039] As an optional case, see figure 1 and 4 , used for light alloy motor housing casting equipment, the inside of the second housing 2 is provided with an auxiliary device 6, the auxiliary device 6 includes a long rod 601, a first gear 602, a second gear 603, a screw 604, a sleeve 605, The horizontal plate 606 and the wide plate 607, the left side of the outer wall of the long rod 601 is rotatably connected to the upper left side of the second housing 2 through a bearing, the left side of the outer wall of the long rod 601 is fixed with a first gear 602, the first gear 602 The bottom is meshed with a second gear 603, the bottom of the second gear 603 is fixed with a screw 604, the outer wall of the screw 604 is threadedly connected with a sleeve 605, and the left side of the outer wall of the sleeve 605 is concave with the left side of the inner wall of the second housing 2. The grooves are slidably connected, and the left side of the outer wall of the sleeve 605 can move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com