Heavy double-spindle integral ball valve whirlwind lathe

A dual-spindle, whirlwind technology, applied in the field of machinery, can solve the problem of difficulty in ensuring accuracy, and achieve the effect of improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings:

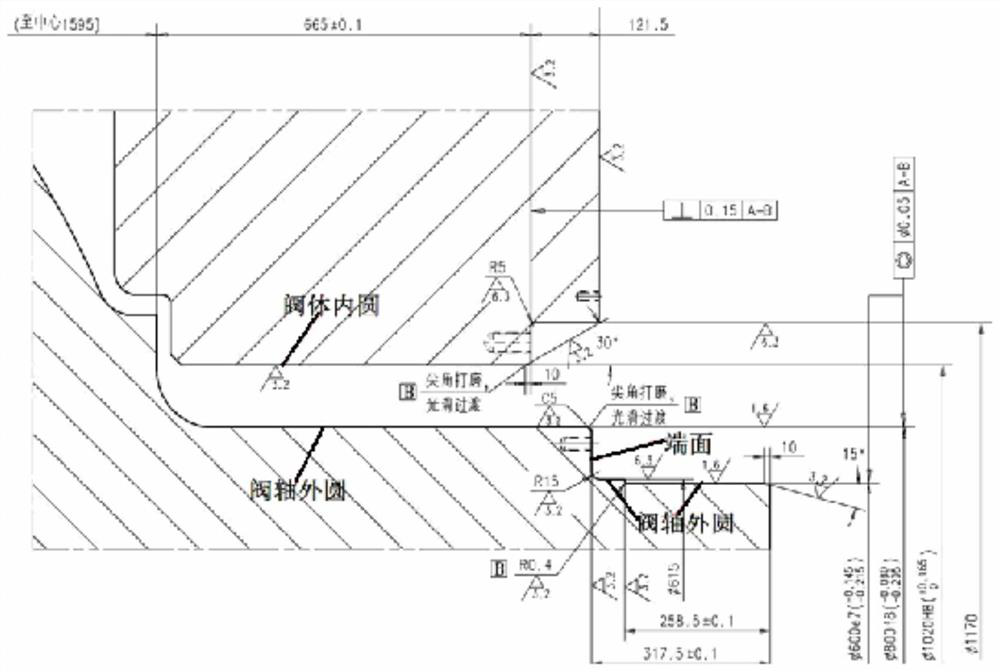

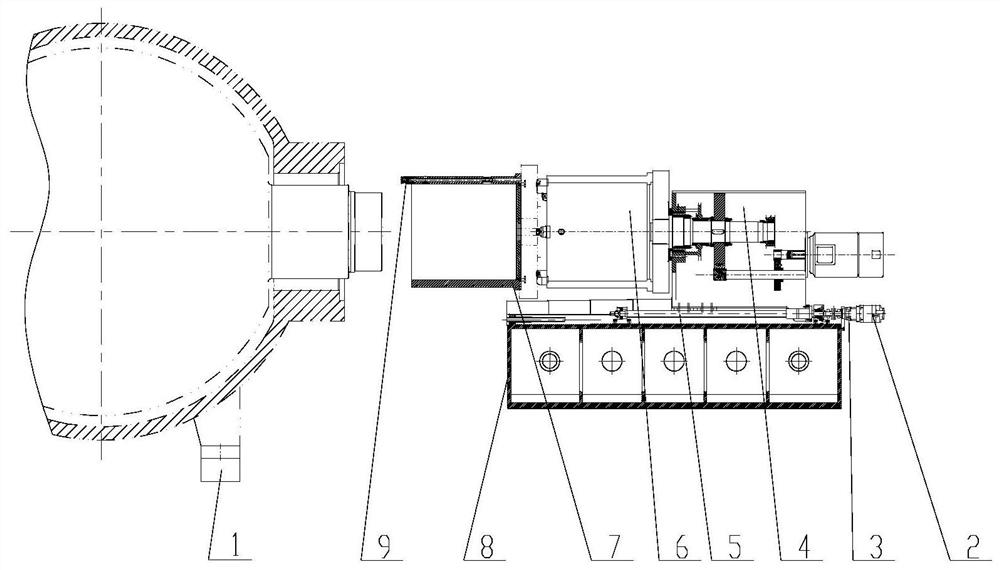

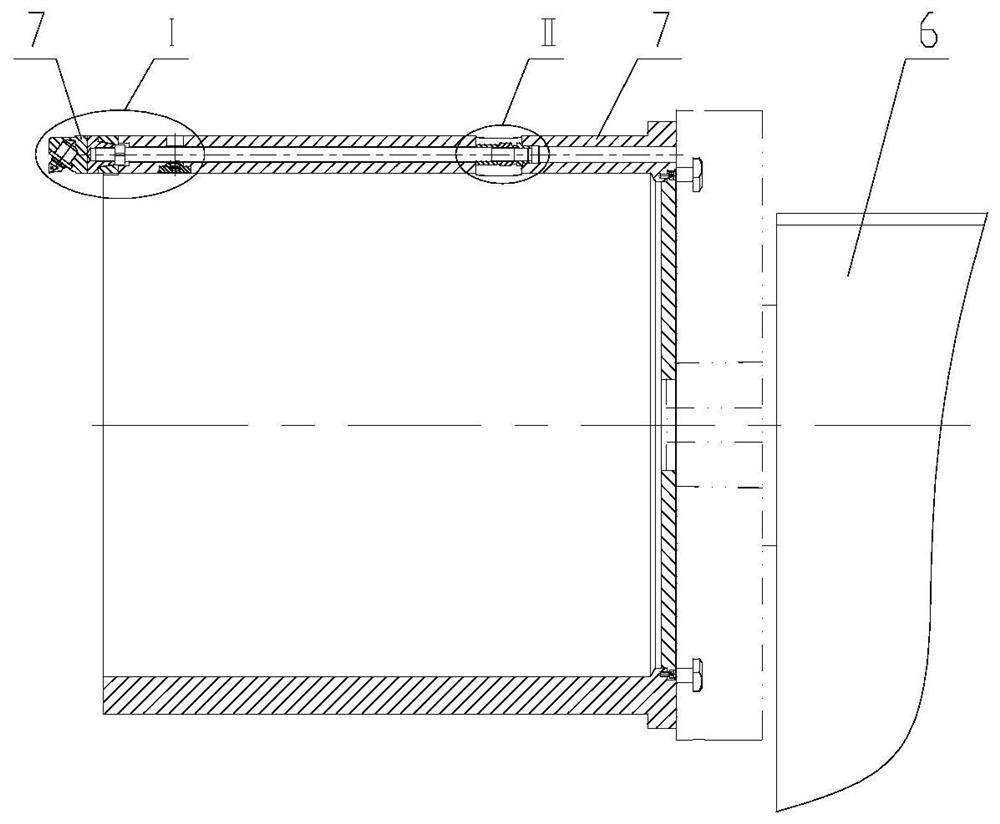

[0018] Depend on Figure 1 to Figure 5 As shown, a heavy-duty double-spindle integral ball valve cyclone lathe includes left-right symmetrical cyclone lathe bodies, and the workpiece is placed between the left and right cyclone lathe bodies and fixed on a square box block 1 . The cyclone lathe body includes a bed body 8 on which a ball screw 5 is connected, a nut is connected on the ball screw 5, and a cyclone milling head box 4 is fixed on the nut. One end of the ball screw 5 is connected to the reducer 3 through an elastic die coupling, and the input end of the reducer 3 is connected to an AC servo motor 2. The elastic die coupling has the characteristics of no backlash and high torsional rigidity. , which can not only eliminate the problem of different transmission caused by the coaxial and angular errors between the ball screw and the reducer, but also effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com