Sand blasting machine for glass

A sandblasting machine and glass technology, applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve problems such as unstable placement and glass bottom scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

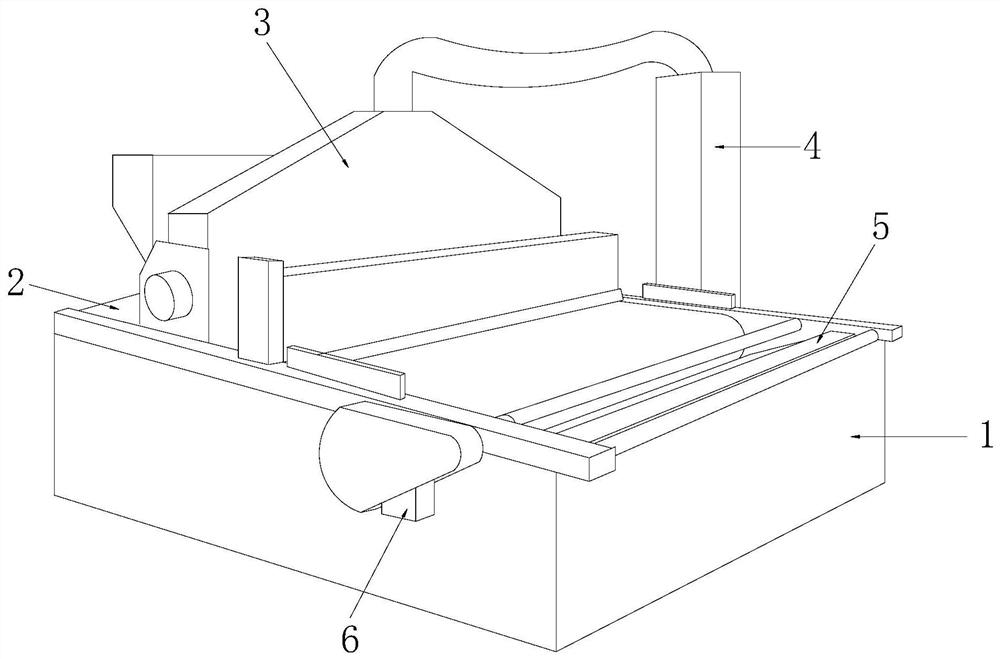

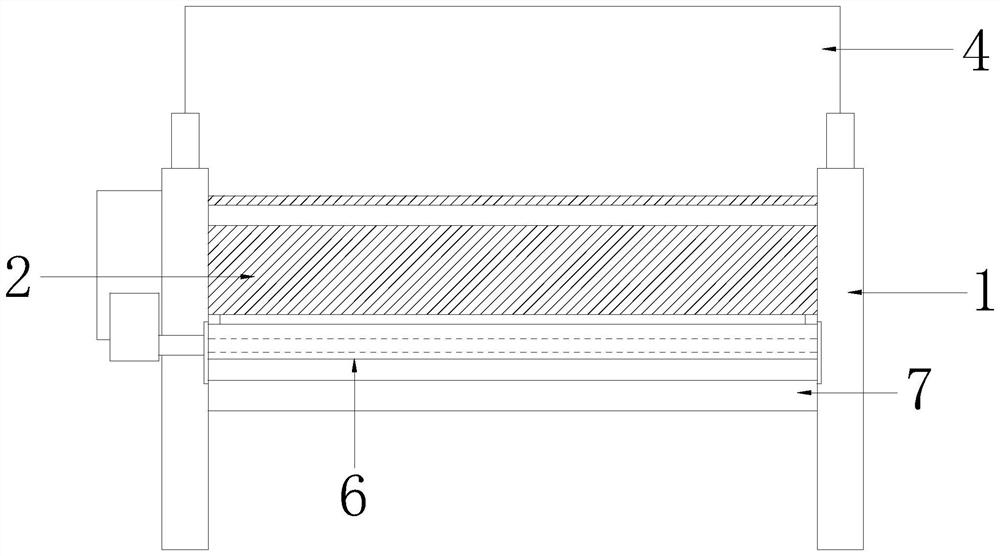

[0030] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of technical scheme of glass blasting machine:

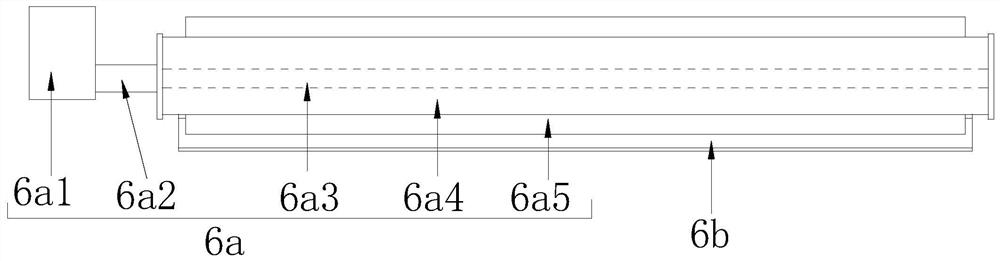

[0031] Such as Figure 1-Figure 3 As shown, a glass sandblasting machine, its structure includes equipment main body 1, conveyor belt 2, sandblasting box 3, dust remover 4, sand return box 5, auxiliary dust removal device 6, said conveyor belt 2 is installed on equipment main body 1 On the upper surface, the sandblasting box 3 is located on the left side of the upper surface of the equipment main body 1, and is located above the conveyor belt 2, the dust collector 4 is matched with the sandblasting box 3, and the sand return box 5 is installed on the equipment main body 1 Inside on the right side, and located on the lower surface of the conveyor belt 2, the auxiliary dust removal device 6 is located at the lower part of the right end of the conveyor belt 2. The auxiliary dust removal device 6 includes a noodle belt cleaning mechanism 6a and an aux...

no. 2 example

[0040] Such as Figure 6-Figure 7 As shown, the present invention provides a kind of technical scheme of glass blasting machine:

[0041] Such as Figure 6-Figure 7 As shown, a glass blasting machine, its structure includes the auxiliary desanding structure 6b including an arc net 6b1, a bomb seat 6b2, and a wiper head 6b3. 1-phase welding, the said spring seat 6b2 is provided with five pieces and is installed on the upper surface of the arc net 6b1 in a uniform and equidistant shape, and the said wiper head 6b3 is provided with five pieces and respectively matched with the upper surface of the spring seat 6b2, which is beneficial to Realize that the sand dust attached to the surface of the wiper cover 6b53 is frictionally shedding and matched.

[0042] Such as Figure 6 As shown, the combined height of the spring seat 6b2 and the wiping head 6b3 is in contact with the spring pressing rod 6a52, which is beneficial to realize the friction and shedding cooperation after conta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap