Slicing device for food processing

A slicing device and food processing technology, applied in metal processing and other directions, can solve the problems of low slicing efficiency, uneven thickness, time-consuming and labor-intensive, etc., and achieve the effect of saving time, slicing consistent thickness and avoiding rust on the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

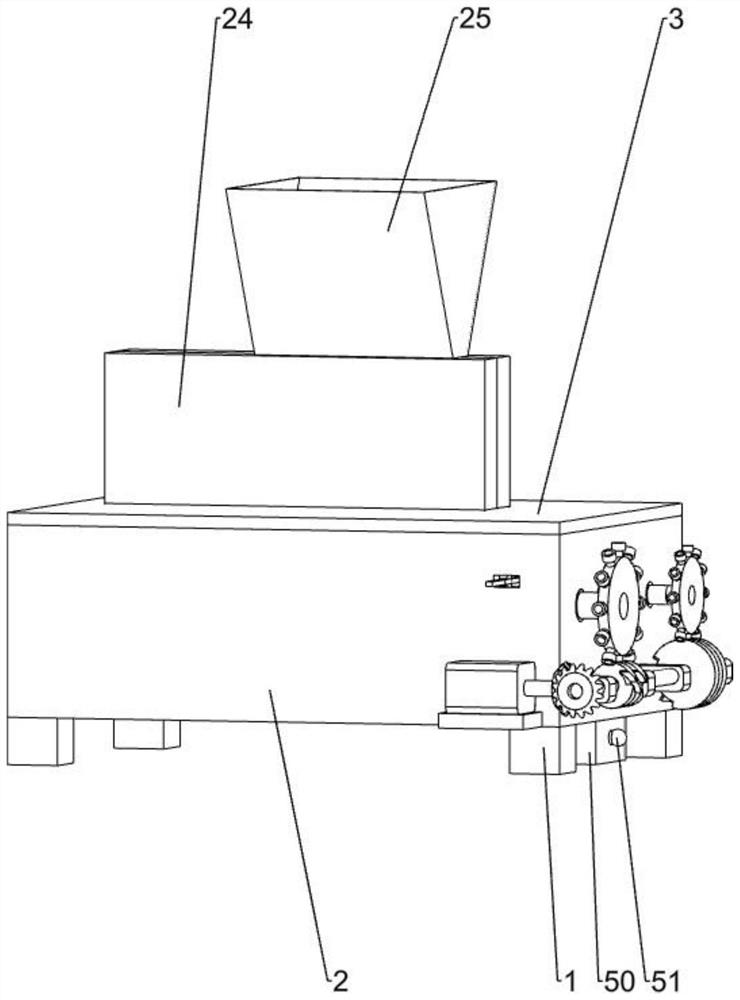

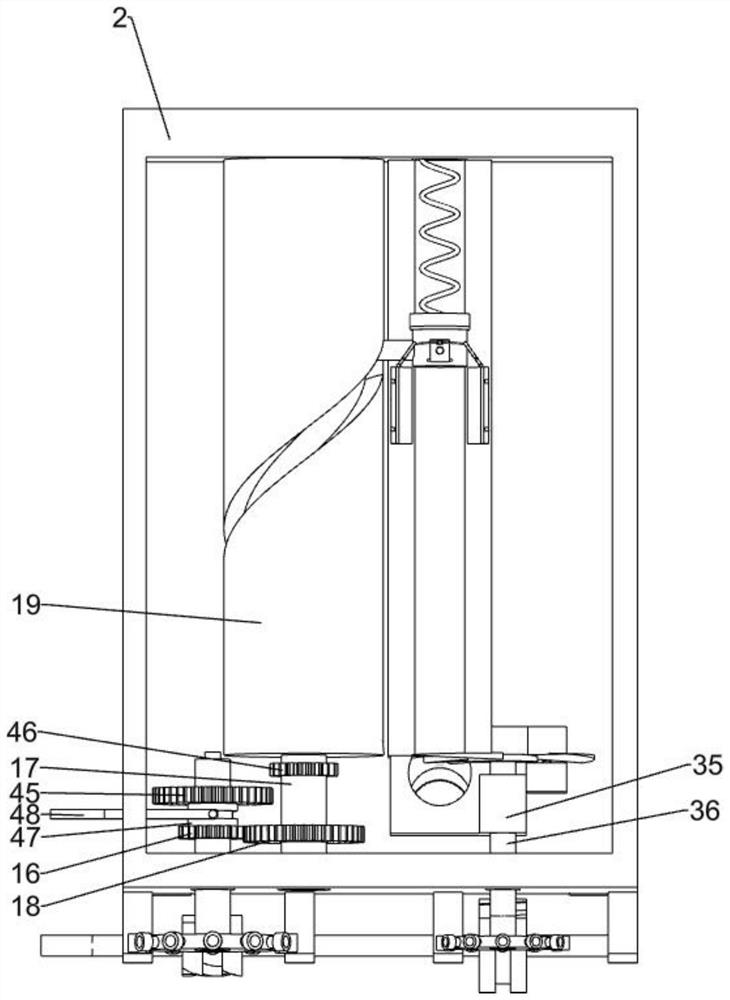

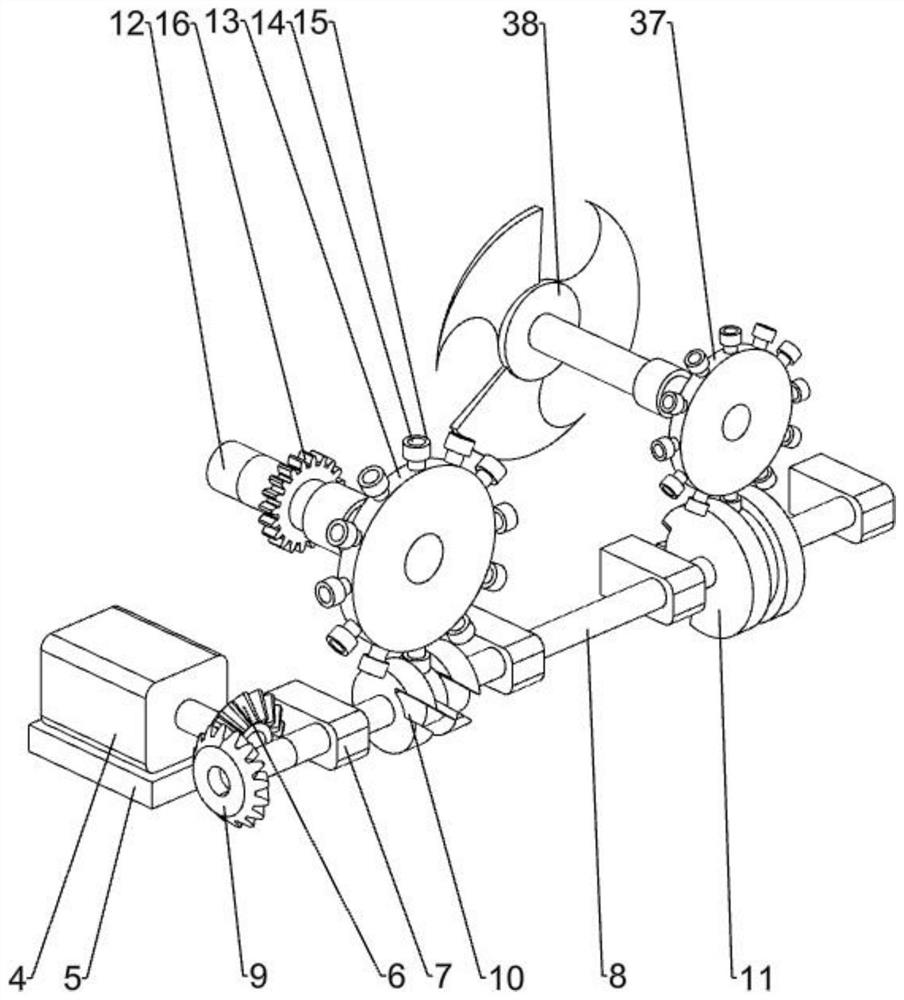

[0029] A food processing slicing device, such as Figure 1-6 As shown, it includes a base 1, a casing 2, a cover 3, a power mechanism, a pushing mechanism and a cutting mechanism. The casing 2 is fixedly installed above the four bases 1. Above the shell 2, the power mechanism is installed on the right side of the shell 2, the pushing mechanism is installed on the front side of the shell 2 inside, and the cutting mechanism is installed on the rear side of the shell 2 inside.

[0030] The base 1 supports the entire device, the outer shell 2 plays a fixed role, and the installation of the cover plate 3 protects the mechanism inside the outer shell 2 to prevent dust from falling into the outer shell 2. When the food is sliced, it passes through the power mechanism Drive the pushing mechanism to push the food to be sliced forward, and then slice the food by the cutting mechanism.

[0031] The power mechanism includes a motor 4, a support plate 5, a first cone wheel 6, a rectangu...

Embodiment 2

[0038] On the basis of Example 1, such as figure 1 , Figure 7-9 As shown, it also includes a blanking box 25, a first spring 26, a top plate 27, a third shaft 28, a push rod 29, a spring bar 30, a second connecting column 31, a fourth shaft 32, a supporting plate 33 and a second spring 34. The lower material box 25 is installed above the feed port 24, the circular hole on the feed port 24 has a rectangular slot, the top plate 27 is installed in the rectangular slot on the feed port 24, and the top plate 27 is installed on both sides. Three shafts 28, the top plate 27 is rotatably connected with the rectangular groove on the feed port 24 through the third shaft 28, the first spring 26 is installed between the rectangular groove and the top plate 27, the top plate 27 is in contact with the push column 20, and the upper left side of the top plate 27 Rotation is installed with push rod 29, and push rod 29 tops are in the rectangular groove above, and push rod 29 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com