Automatic blowback emptying device applied to blockage of filter tip rod conveying pipeline

A technology for conveying pipes and filter rods, applied in the directions of conveyors, transportation and packaging, can solve the problems of equipment downtime, long distance between the receiving end and the transmitting end of filter rod conveying, and increasing the labor intensity of operators, so as to eliminate the equipment. The effect of downtime, increased productivity, reduced workload and responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

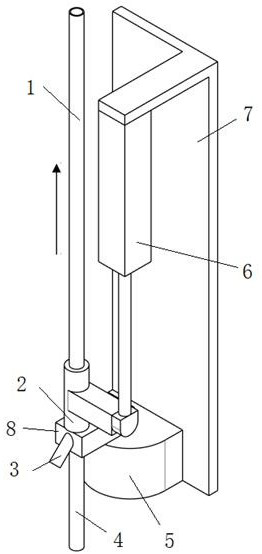

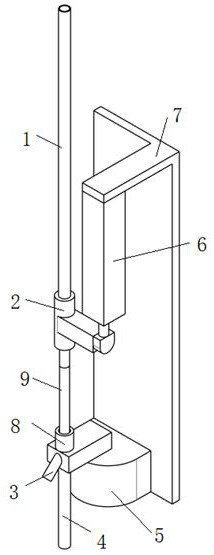

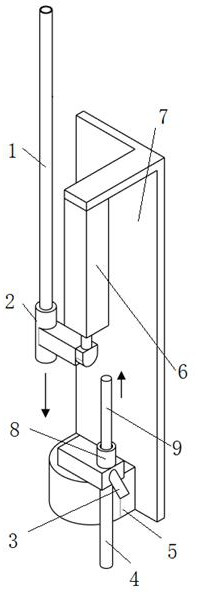

[0021] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0022] Such as Figure 1-4 As shown, a device for automatically blowing back and emptying the blockage of the filter rod 9 conveying pipeline 1 includes a launching end 10, a conveying pipeline 1, a pulling mechanism 6 and a rotating mechanism 5, between the launching end 10 and the conveying pipeline 1 A pulling mechanism 6 and a rotating mechanism 5 are provided, and the conveying pipeline 1 is connected to the receiving end 11. The dislocation and reset docking between the transmitting end 10 and the pipeline 4 of the conveying hanger is realized through the pulling mechanism 6 and the rotating mechanism 5. In the pulling mechanism 6 A joint is provided at the butt joint with the rotating mechanism 5; an air blowing mechanism 3 is arranged on the pulling mechanism 6 or the rotating mechanism 5 communicating with the launching end 10, and the filter in the pulling mechanism 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com