Dry quenching coke tank and production method

A technology of coke coke and dry quenching, applied in the field of metallurgical equipment manufacturing, can solve the problems of low life and easy cracking of coke tank lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

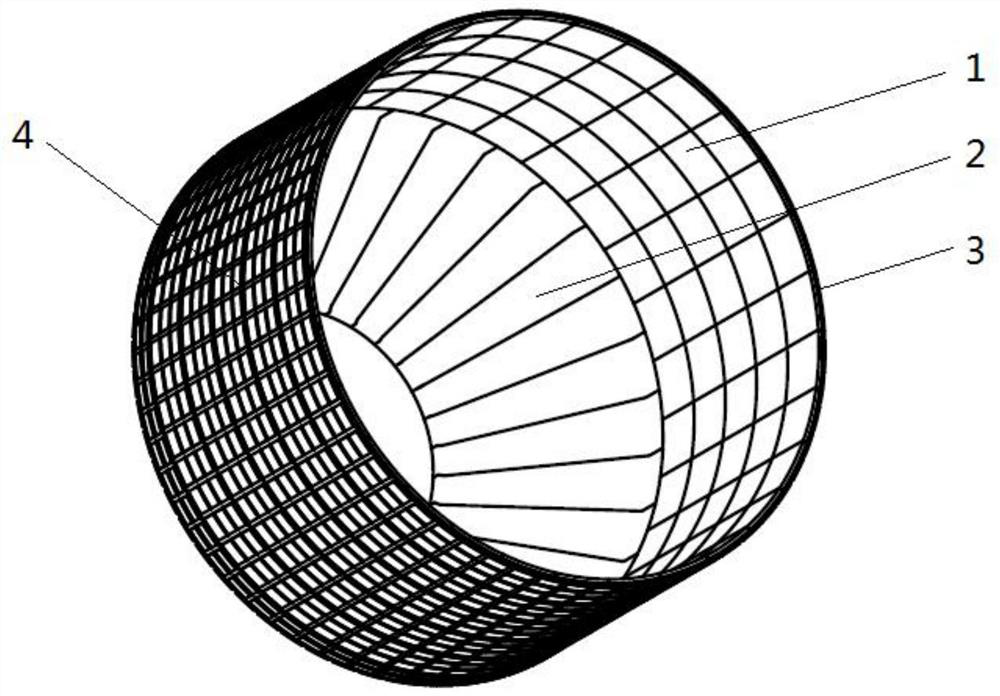

[0031] The invention provides a dry quenching coke tank, which comprises a coke tank body, the coke tank body includes a tank body, a refractory fiber felt 3 and a grid; the tank body is formed by masonry and splicing of lining boards; the surface of the refractory fiber felt 3 is evenly laid On the outer surface of the tank body; the grid is stretched and covered on the outer surface of the refractory fiber felt 3 . like figure 1 As shown, the steel structure and anchors are too small in size and are not marked in the figure.

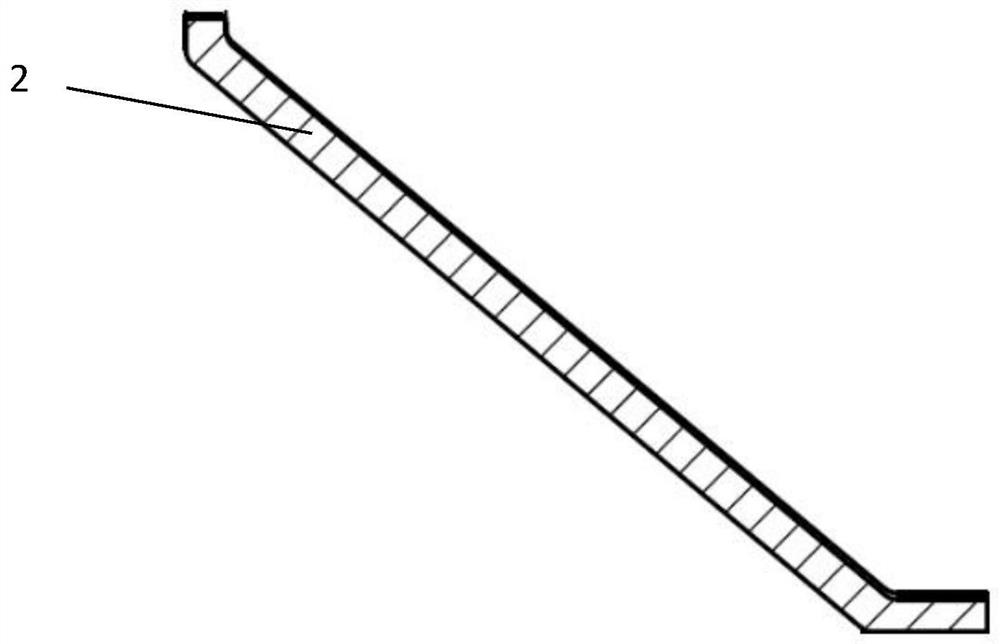

[0032] Further, the tank body includes a cylindrical section tank body and a cone section tank body connected to the bottom of the cylindrical section tank body, and the liner prefabricated block also includes a cylindrical section liner prefabricated block 1 and a cone section liner prefabricated block 2. The tank body of the cylindrical section is formed by masonry and splicing of the prefabricated block 1 of the lining plate of the cylindrical sect...

Embodiment 2

[0039] The invention provides a method for producing a CDQ coke tank, which is used to manufacture the CDQ coke tank provided by the invention, comprising the following steps:

[0040] The liner prefabricated block is formed, and the high-strength refractory castable is molded and then fired at a high temperature to obtain the liner prefabricated block; the tank body is formed, and the liner prefabricated block is spliced to obtain the tank body; the refractory fiber felt 3 is laid, Wrap a layer of refractory fiber felt 3 on the outer surface of the tank body; lay a grid, lay a layer of grid on the outer surface of the refractory fiber felt 3, stretch and fix the grid so that the grid is wrapped in a stretched state The outer surface of the refractory fiber felt 3 is used to obtain the main body of the coke tank; the installation is fixed, and the main body of the coke tank is installed in the matching structural steel to obtain the coke tank for CDQ.

[0041] In this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com