A kind of FRP prestressed tendon ballastless track slab and preparation method thereof

A technology of prestressed tendon and ballastless track, which is applied in the direction of track, road, ballast layer, etc., can solve the problems of reducing the durability of the track slab, reducing the insulation effect, and high cost, so as to improve fatigue resistance and durability, reduce the The effect of insulation cost and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation modes of the present invention will be further described below in conjunction with the accompanying drawings.

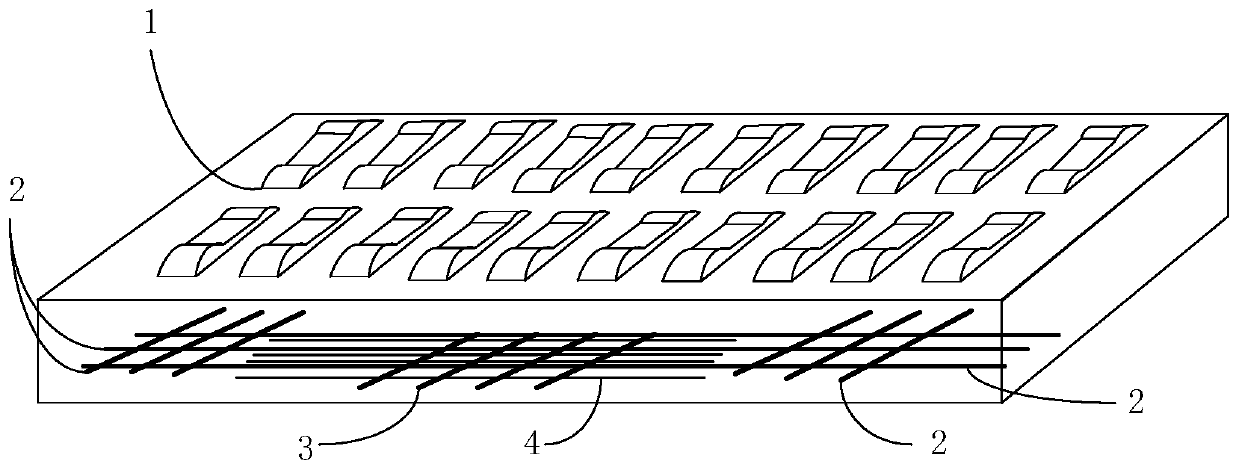

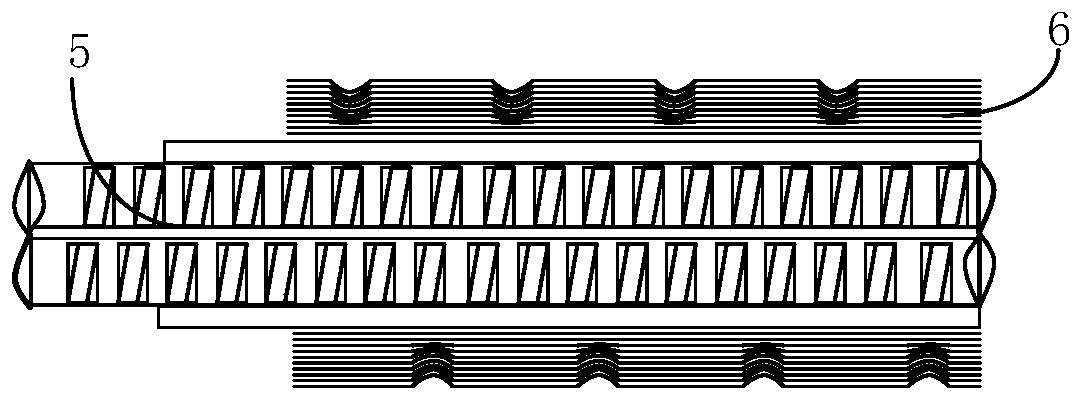

[0026] like Figure 1-6 As shown, an FRP prestressed tendon ballastless track slab includes a slab body 1, and FRP prestressed tendons 2 are arranged inside the slab body 1. Among them, the FRP prestressed tendons 2 are made of various fiber composite materials including basalt fiber, aramid fiber and carbon fiber through the extrusion molding process. Several FRP prestressed tendons 2 are arranged along the longitudinal and transverse directions of the plate body 1. The clip-type anchorage adopts the pretensioning method to pre-stretch the FRP prestressed tendons 2, so that the quantity, position and prestressed size of the FRP prestressed tendons 2 can meet the specification requirements of ballastless track slabs.

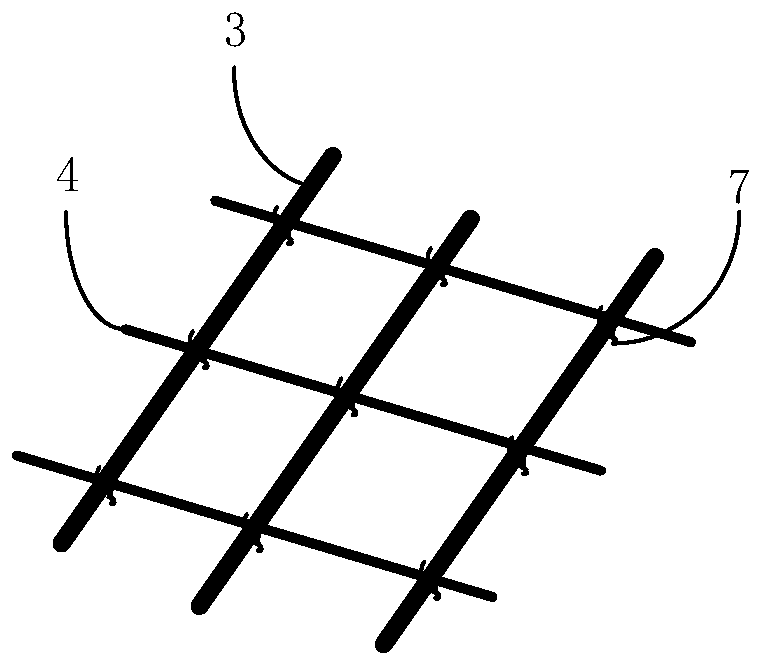

[0027] Steel-continuous fiber composite bars 3 and high-strength steel bars 4 are also arranged inside the plate body 1, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com