Self-stress bridge continuous construction structure based on simply supported steel beams and construction method thereof

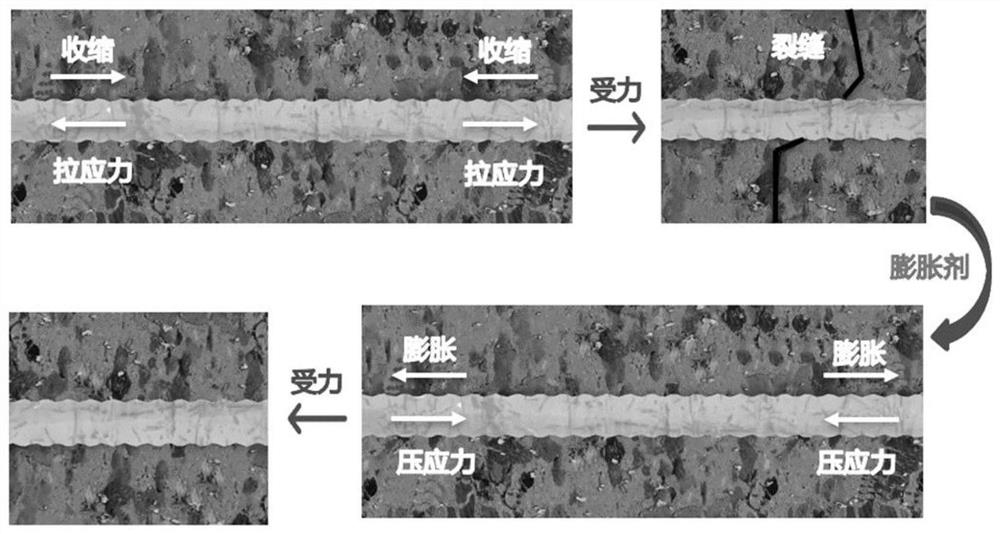

A technology of self-stress and steel girders, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of lack of continuous structural structures and construction methods, large differences in self-stress values, and no self-stress connecting plates, etc., to achieve The expansion response is compact, the elastic modulus is close, and the effect of improving the coordination of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

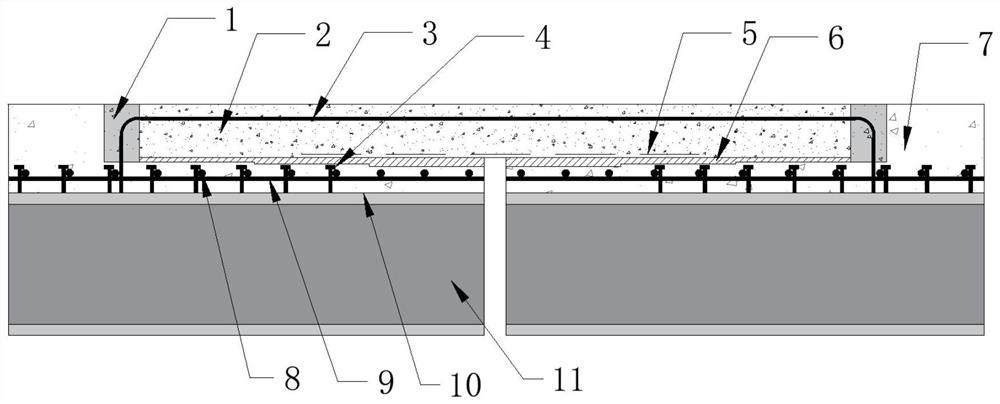

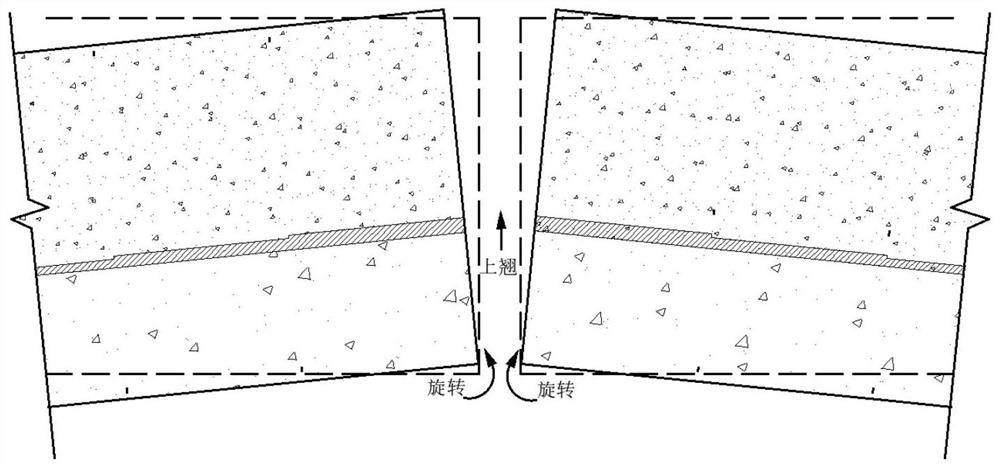

[0079] A self-stressed bridge continuous structural structure based on simply supported steel beams, such as Figure 1-5 As shown, it includes a self-stressing connection plate 2, an elastic deformation layer 1, a bridge deck pavement layer 7, a buffer energy-absorbing layer 6 and a connection structure;

[0080] The self-stressed connecting plate 2 is located between the two H-shaped steel beams 11, and the self-stressed connecting plate 2 is made of self-stressed concrete material through formwork casting, and the bottom of the self-stressed connecting plate 2 is provided with a debonding tape 5;

[0081] The elastic deformation layer 1 is arranged at both ends of the self-stressed connecting plate and is an elastic concrete material;

[0082] The bridge deck pavement layer 7 is located above the H-shaped steel beam 11, and an interface adhesive 10 is applied between the H-shaped steel beam 11 and the bridge deck pavement layer 7. The interface adhesive 10 is made of vinyl a...

Embodiment 2

[0087] A self-stressed bridge continuous structural structure based on simply supported steel beams, as described in Example 1, the difference is that the length of the self-stressed connecting plate 2 is 3.8m in span length and 3.8m in thickness of two adjacent bridge spans. The width of 0.12m is set according to the width of each linear meter (1m); the length of the debonding tape is 2 meters, and the material of the debonding tape 5 is 350# roofing paper, which has strong tensile ability and can better adapt to H-shaped steel beams It can be stretched and deformed with the self-stressed connecting plate, and at the same time, the waterproof performance is excellent, and it is preferably set in the middle part of the length of the self-stressed connecting plate;

[0088] The elastic concrete material of the elastic deformation layer 1 includes polyurethane binder, cement, standard sand and fibers, which are mixed and stirred. The polyurethane binder includes two components, p...

Embodiment 3

[0093] A self-stressed bridge continuous structural structure based on simply supported steel beams, as described in Example 2, the difference is that the bridge deck pavement layer 7 sequentially includes modified asphalt concrete surface layer, epoxy resin waterproofing layer from top to bottom Adhesive layer and C40 ordinary concrete layer, the interface adhesive 10 is applied between the C40 ordinary concrete layer and the H-shaped steel beam, and the lower part is a steel mesh formed by binding longitudinal steel bars and structural steel bars, and the bridge deck pavement layer The structure of each material functional layer is not much different from the traditional bridge deck pavement layer. figure 2 In the unified use of concrete symbols;

[0094] The longitudinal part of the inverted U-shaped steel bar 3 is 30mm away from the top of the self-stressed connecting plate 2, and the inverted U-shaped steel bar is preferably 3.9 meters long and 0.19 meters high, HRB335, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com