Forming method of integral wallboard

A molding method and overall technology, applied to the preparation of walls, formwork/formwork/work frames, and building components on site, can solve vertical cracks at the joints of unit walls, obstacles to the healthy development of inner walls, and damaged joints. Problems such as deformation tracking of seam materials, to achieve the effect of reducing punching and splicing processes, stable molding, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

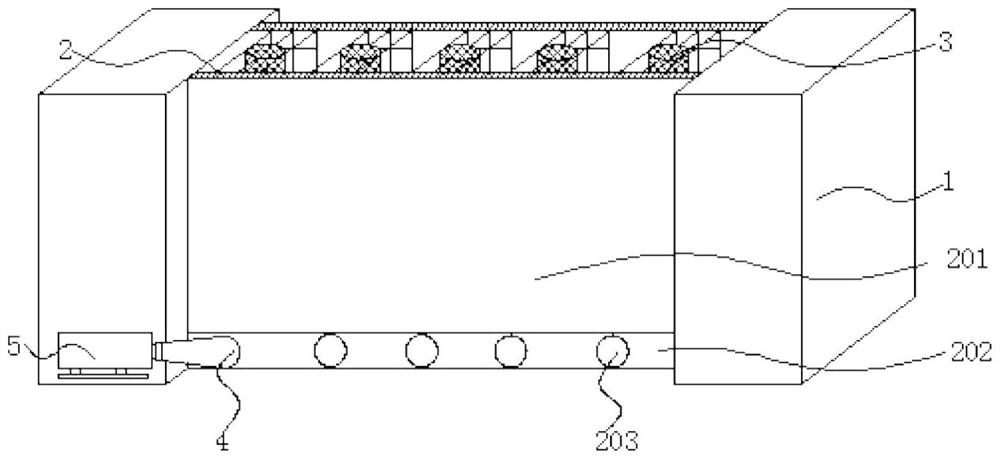

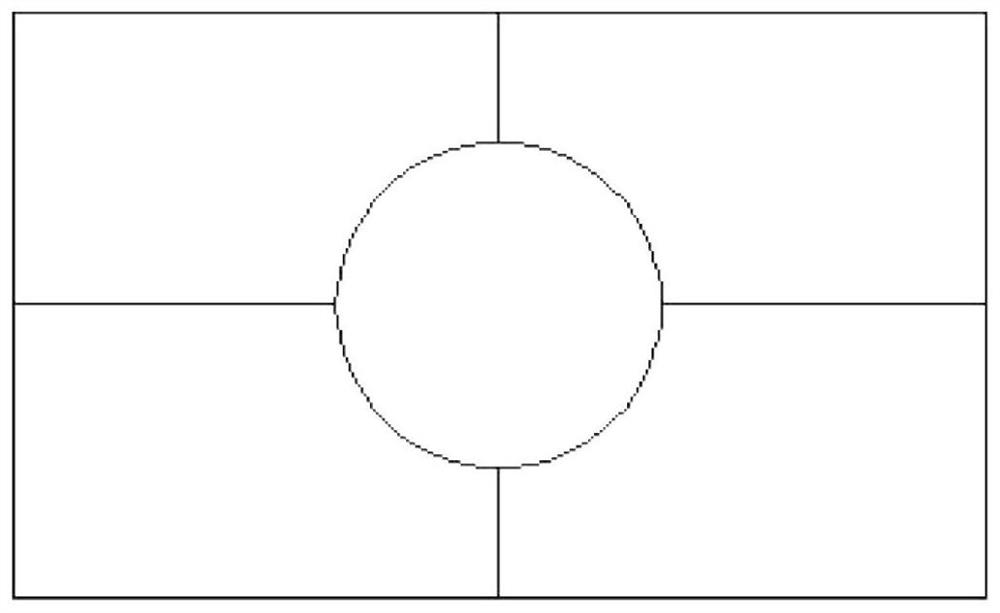

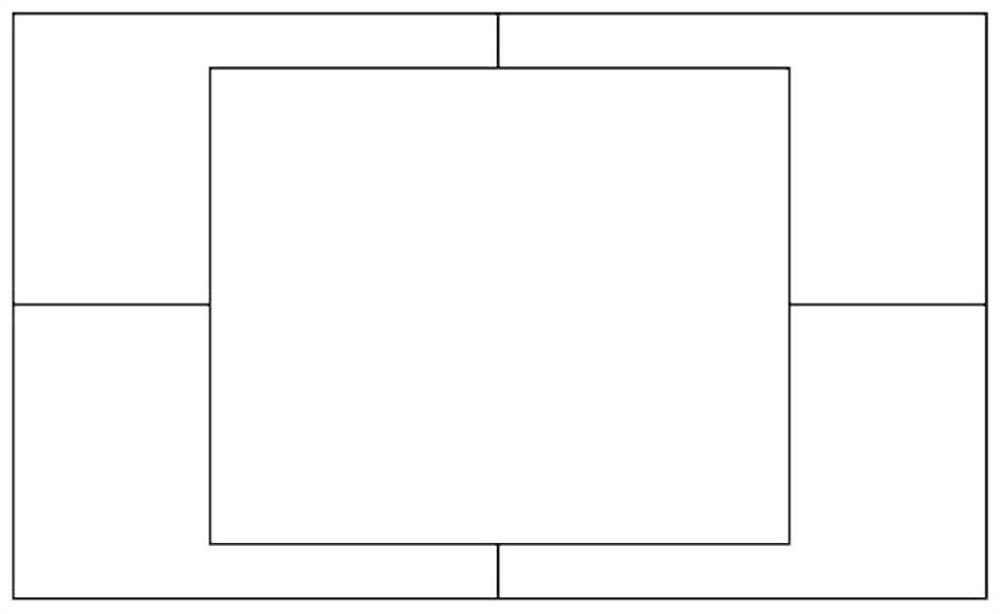

[0022] Such as figure 1 , figure 2 As shown, the molding method of the integral wallboard, the integral wallboard is an integral wallboard with a central hole, when the thickness of the integral wallboard is 10cm:

[0023] The first step is to set the supporting mold 2. The supporting mold 2 includes side plates 201, bottom plates 202, holes 203 and steel bars 204. The two side plates 201 are arranged on both sides of the preformed wall, and the left and right sides of the two side plates 201 The two ends are stuck between two load-bearing columns 1, the bottom plate 202 is provided with the lower end of the side plate 201, and a steel bar 204 is arranged at the connection between the side plate 201 and the bottom plate 202 and is located inside the support mold 2, and the length of the steel bar 204 is the same as the The length of the whole wallboard is the same, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com