A method of shock-absorbing laying of pipelines

A pipeline and shock-absorbing technology, which is applied in the direction of pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of high work intensity of construction personnel, achieve the effect of reducing work intensity and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

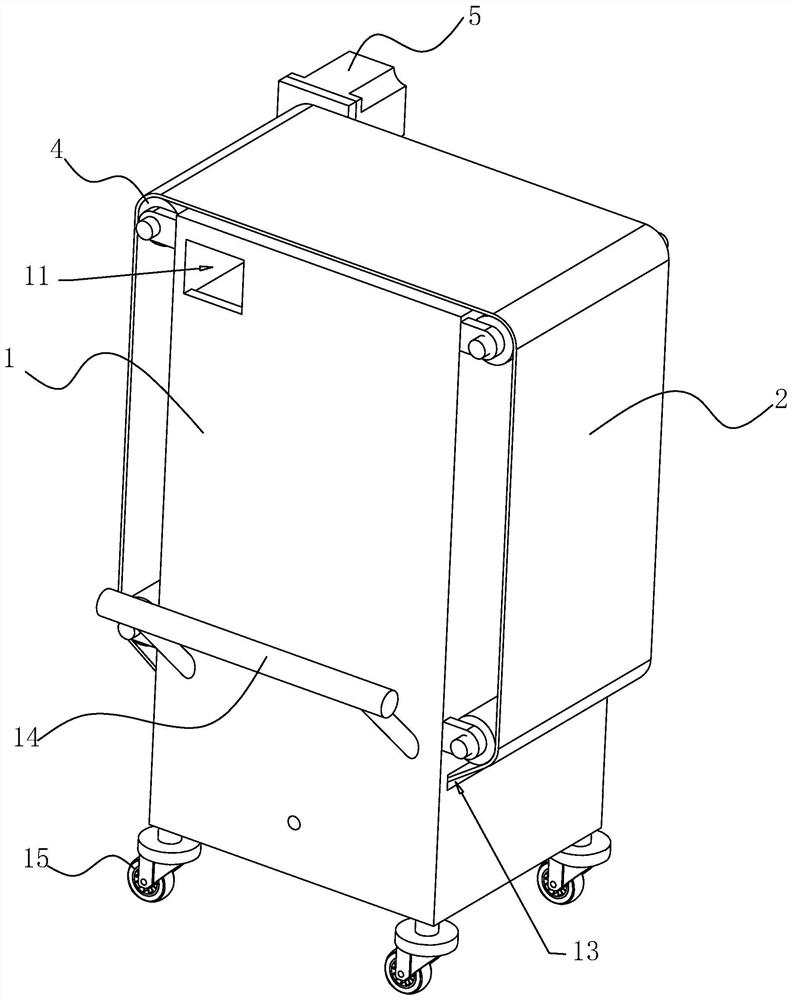

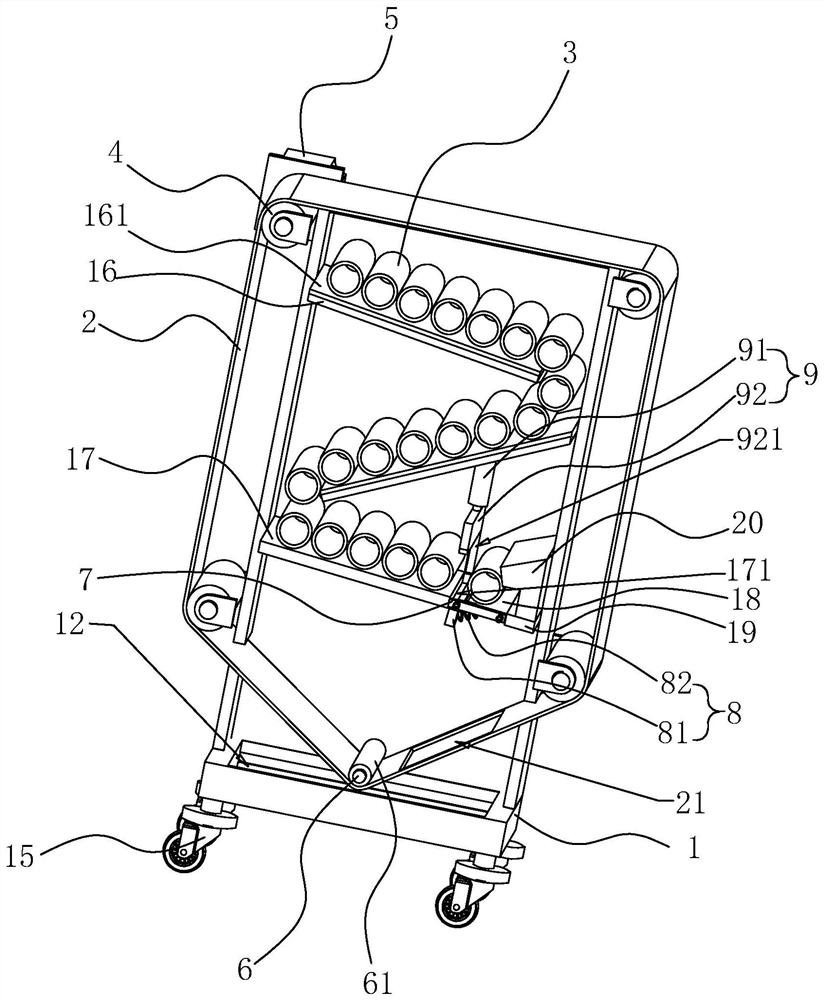

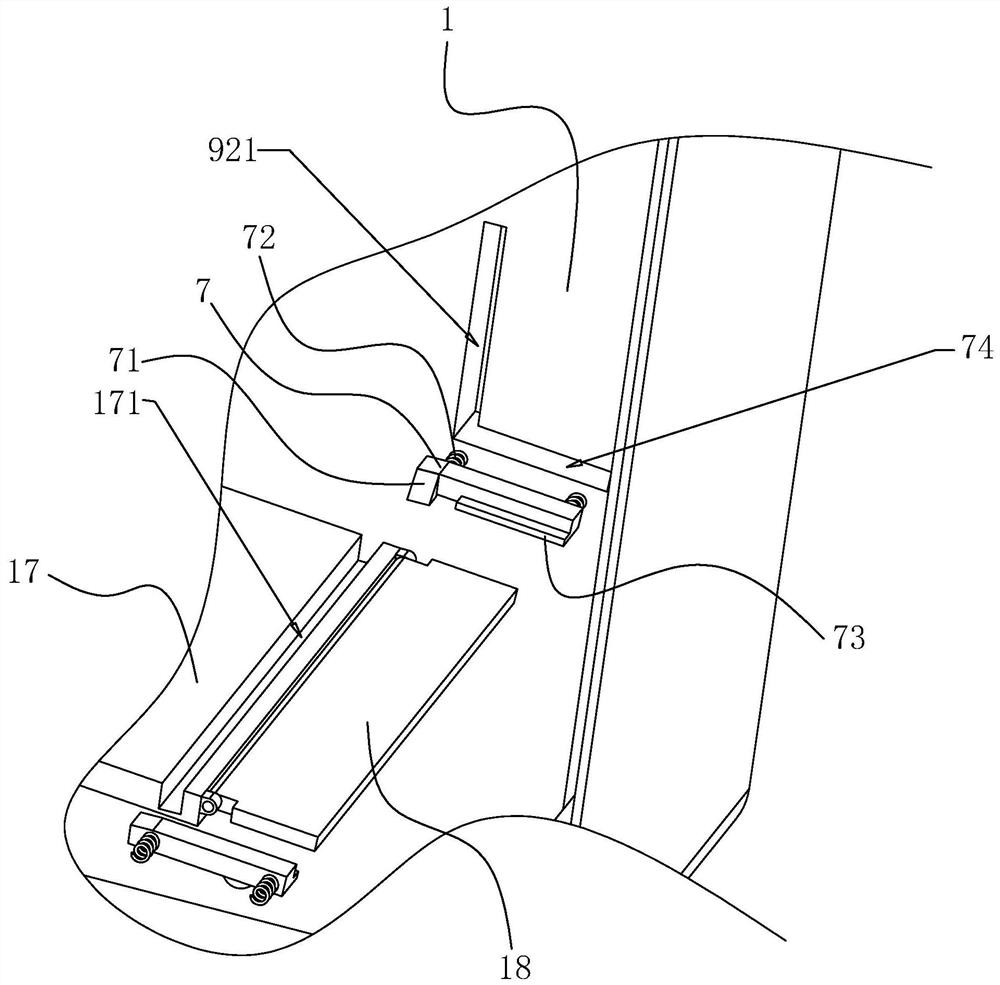

[0035] The following is attached Figure 1-3 The application is described in further detail.

[0036] The embodiment of the present application discloses a shock-absorbing laying method of a pipeline. refer to figure 1 and figure 2 A method for laying shock absorbers for pipelines comprises the following steps:

[0037] Step 1: Prefabricate the mobile pipe-releasing device;

[0038] Step 2: Preparation of pipeline monomers: Load each pipeline monomer 3 into the mobile pipe laying device one by one:

[0039] Step 3: Place the pipeline monomers: move the mobile pipe releasing device to the installation position corresponding to each pipeline monomer 3, and lower the pipeline monomers 3 one by one;

[0040] Step 4: Splice the adjacent pipeline monomers and fix them at the installation position;

[0041]The mobile pipe-releasing device comprises a body 1 and four rollers 15 installed and fixed on the lower end surface of the body 1, and the outside of the body 1 is in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com