Thermoelectric unit water supply bypass and transformer main reheating steam temperature wide-range adjusting system

A thermal power unit, reheating steam temperature technology, applied in feed water heater, superheat temperature control, preheating and other directions, to achieve the effect of reducing flue gas temperature, improving furnace efficiency and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

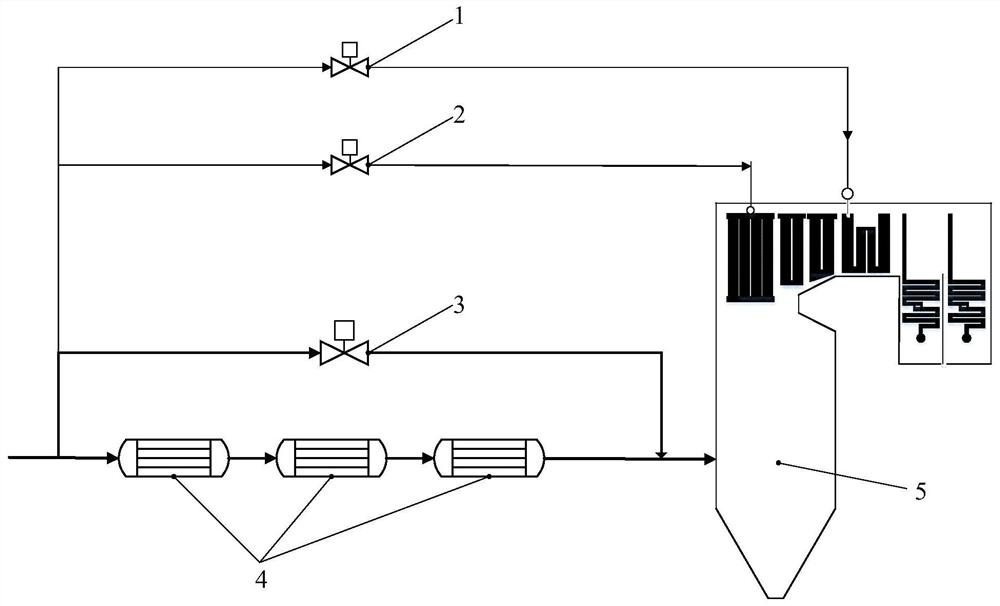

[0027] 1. The high-pressure heater bypass adjustment valve 3 is connected in parallel with the high-pressure heater 4, its inlet is connected to the inlet of the high-pressure heater 4, and its outlet is connected to the outlet of the high-pressure heater 4. The feedwater flow through the high-pressure heater can be continuously adjusted in the range of 0 to 100%, so as to adjust the heating and extraction flow. When the feedwater flow through the high-pressure heater is small, the steam extraction of the steam turbine is less, and the steam extraction for heating can be greatly increased, and the final increase can reach 20% to 30%.

[0028] 2. A main steam temperature regulating valve 2 is added, the inlet of which is connected to the inlet of the high-pressure heater 4, and the outlet is connected to the main steam system of the boiler 5 to form a normal desuperheating system of the main steam. This system is commonly used in the heating period, and can realize the adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com