A method for fabricating an oxidation-enhanced diode

A manufacturing method and diode technology, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of multiple cycles, multiple product classifications, uneven oxidation, etc., and achieve the effects of improving product performance, reducing costs, and reducing process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The invention provides a method for making an oxidation-increased diode. When the method of the invention is growing AlAs, 40-100PPM of O (oxygen) element is added to TMAl, so that the oxidation uniformity of the product is improved. Decrease from 3.09 to 1.77, increase ΔN, improve device performance.

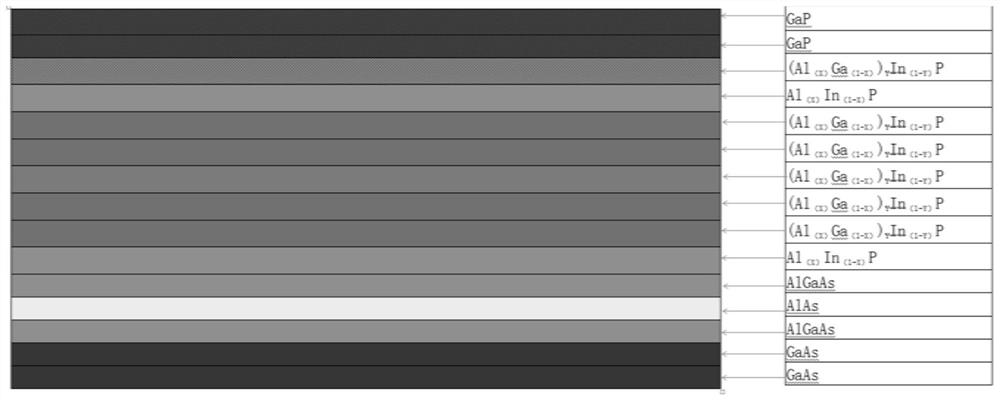

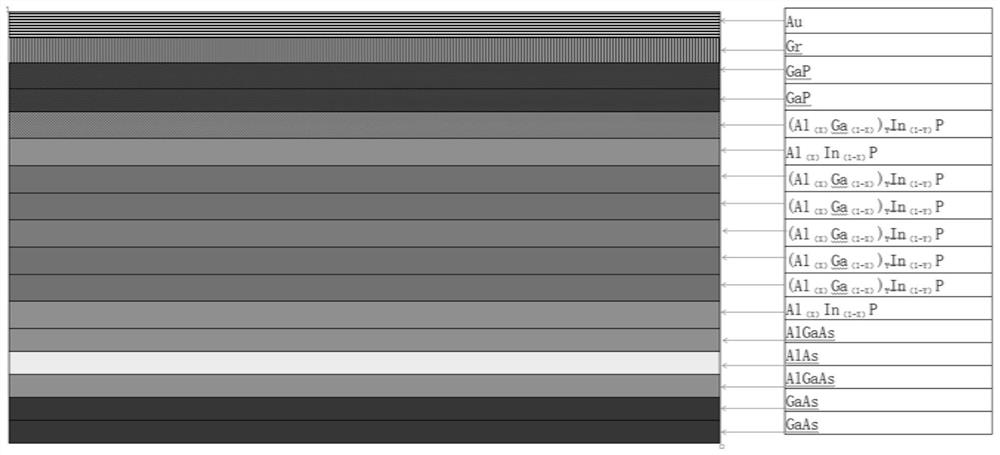

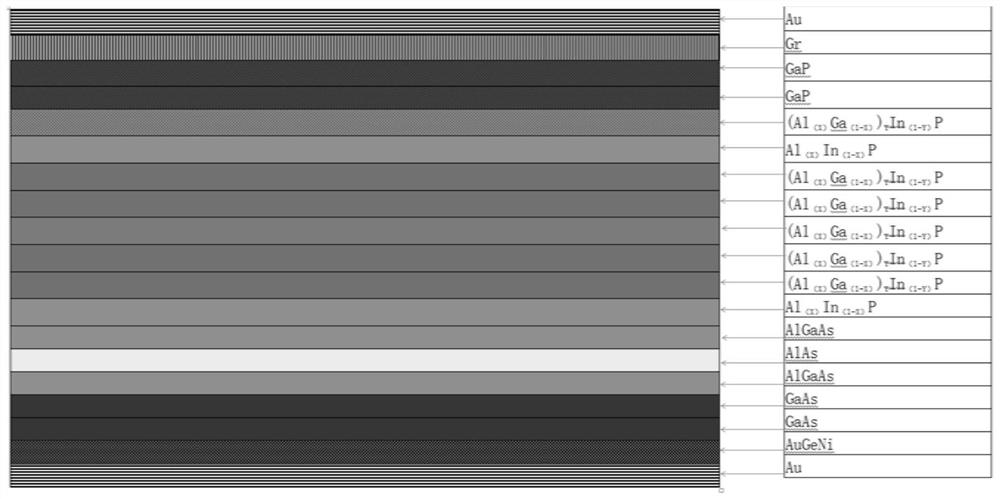

[0034] The method for making an oxidation-enhanced diode provided by the present invention comprises the following steps:

[0035] Step 1. Use epitaxial MOCVD equipment to grow an epitaxial structure on a GaAs substrate. The growth components of the structure are grown sequentially from bottom to top. The growth temperature is 550-700°C, the growth pressure is 40-50 torr, and the preferred pressure is 42 torr. When growing, add 40-100PPM O (oxygen) element in TMAl;

[0036] Step 2, making the front metal electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com