Rotary motor and rotor assembly thereof

A technology for rotating motors and rotors, which is applied in the direction of electric components, electrical components, magnetic circuit rotating parts, etc., which can solve problems such as limiting the performance of motors, and achieve the effect of enhancing reluctance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

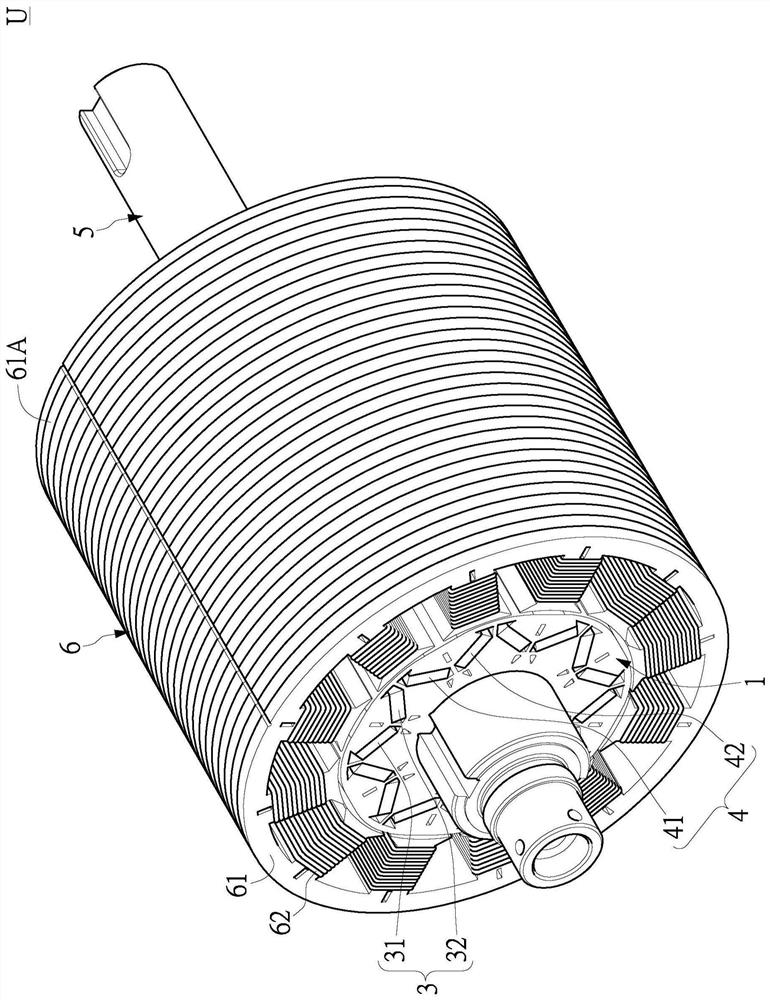

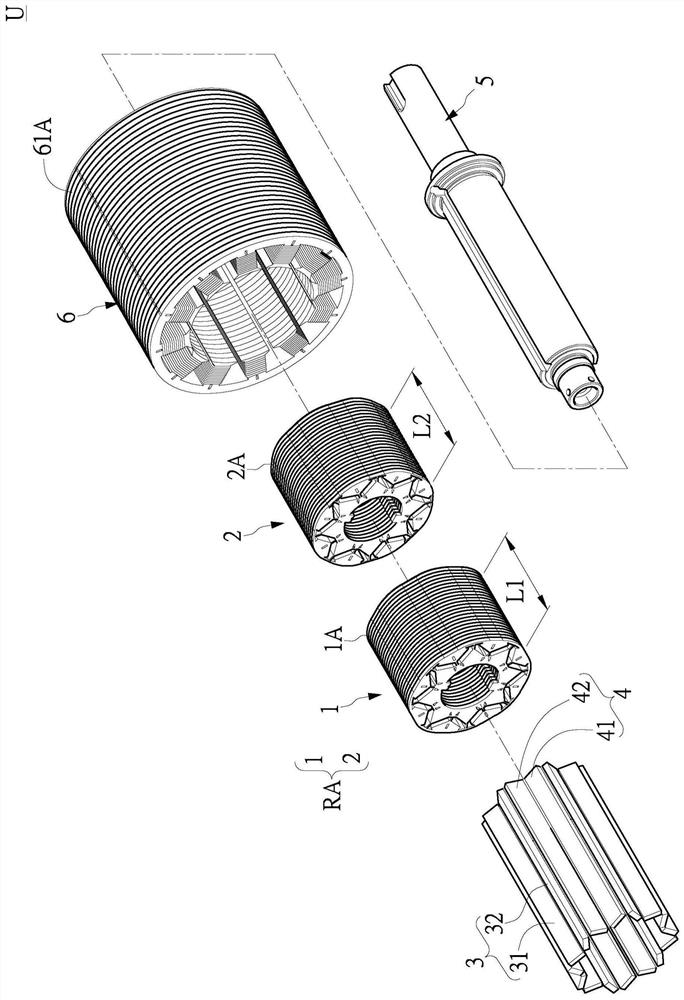

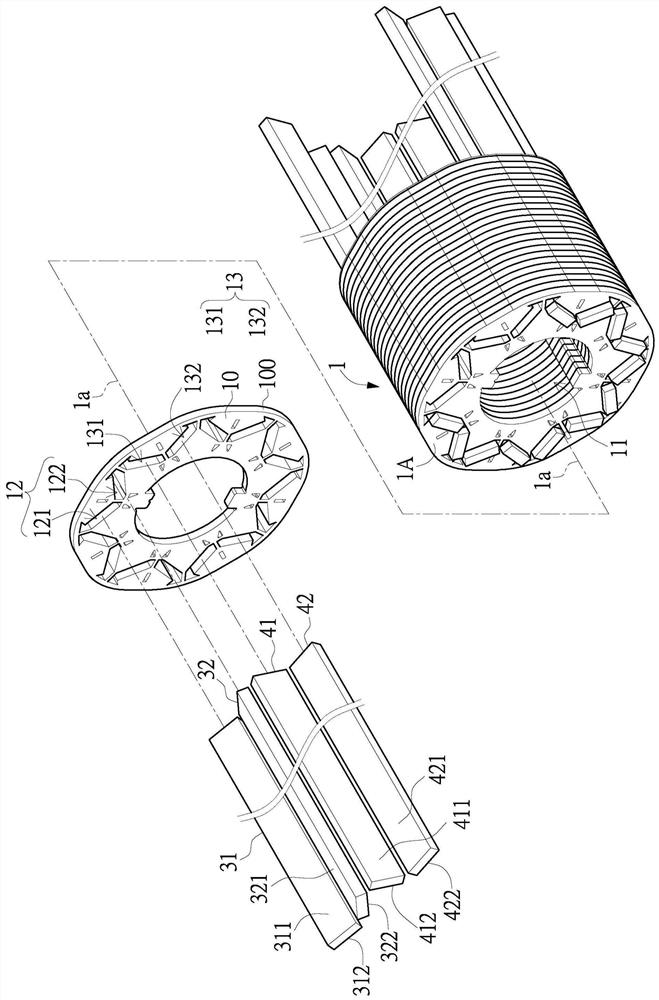

[0037] First, see figure 1 and figure 2 as shown, figure 1 It is a three-dimensional combined schematic view of the rotating electrical machine in the first embodiment of the present invention, figure 2 It is a three-dimensional exploded schematic view of the rotating electrical machine according to the first embodiment of the present invention. The present invention provides a rotating electric machine U and its rotor assembly RA, that is, an electric motor and a rotor applied to the electric motor. The rotary electric machine U may include a rotating shaft 5 , a rotor assembly RA, a first magnetic element set 3 , a second magnetic element set 4 and a stator assembly 6 . The rotor assembly RA can be arranged on the rotating shaft 5, the first magnetic element group 3 and the second magnetic element group 4 can be arranged on the rotor assembly RA, and the stator assembly 6 can be arranged corresponding to the rotor assembly RA, so that the rotor assembly RA can be relati...

no. 2 example

[0061] First, see Figure 10 and Figure 11 as shown, Figure 10 It is a three-dimensional combined schematic view of the rotating electrical machine according to the second embodiment of the present invention, Figure 11 It is a three-dimensional exploded schematic view of the rotating electrical machine according to the second embodiment of the present invention. Depend on Figure 10 and Figure 11 and figure 1 and figure 2 It can be seen from the comparison that the biggest difference between the second embodiment and the first embodiment is that the rotating electrical machine U provided by the second embodiment can be provided with two second rotors 2 .

[0062] Then, the first predetermined length L1 of the first rotor 1 and the second predetermined length L2 of the two second rotors 2 and the distance between the first rotor 1 and the second rotor 2 can be adjusted according to the application occasion of the rotating electrical machine U. Relative position, in ...

no. 3 example

[0065] First, see Figure 12 to Figure 14 as shown, Figure 12 is a schematic perspective view of the first rotor of the rotor assembly of the third embodiment of the present invention, Figure 13 is a schematic front view of the first rotor of the rotor assembly of the third embodiment of the present invention, Figure 14 for Figure 13 An enlarged schematic of part XIV. Depend on Figure 12 and Figure 13 and Figure 3 to Figure 6 It can be seen from the comparison that the salient poles of the first rotor 1 provided by the third embodiment can be arranged on the first quadrature axis Q1 , the first direct axis D1 and the second direct axis D2 at the same time.

[0066] Based on the above, further speaking, the plurality of first segments 1001 , the plurality of second segments 1002 and the plurality of third segments 1003 may be protruding relative to the first rotor body 10 . In this way, a gentle section 1004 that is gently arranged relative to the adjacent first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com