Cable sealing device for permanent magnet synchronous motor

A permanent magnet synchronous motor and cable sealing technology, which is applied to the cable entrance sealing device, electromechanical device, cooling bus device, etc., can solve the problems of hidden dangers in insulation, unresolved sealing, and poor sealing performance, and achieve simple connection Convenient, simple and convenient assembly, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

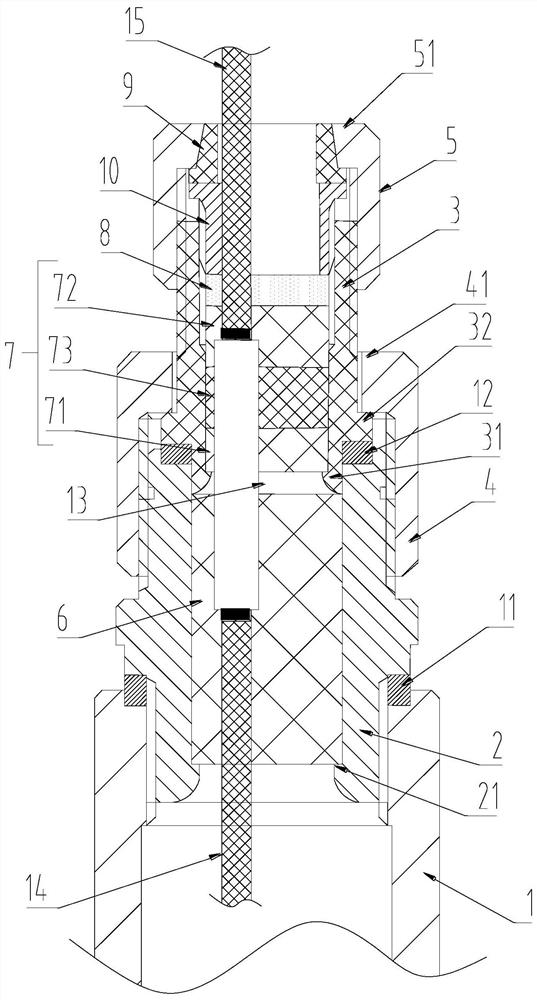

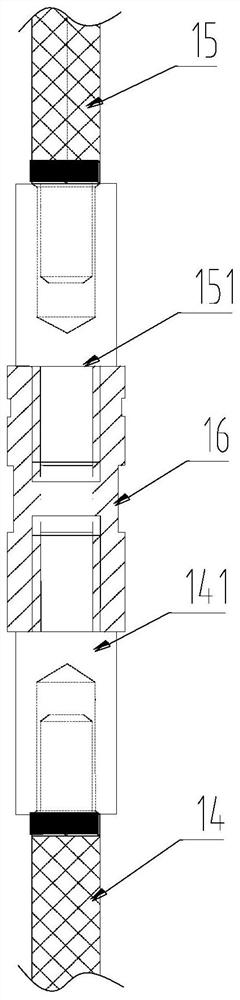

[0036] EXAMPLES: One permanent magnet synchronous motor cable sealing device, such as figure 1 As shown, including the motor outgoing seat 1, three motor outlet cable 14, three upper cable 15, the hollow first sealing joint 2, the sealing cushion in the first sealing joint 2 is connected to the first sealing joint 2 The first block 4 of the outer wall, the hollow second sealing joint 3, is located in the seal 7 in the second sealing joint 3, and the thread is threaded connected to the head 10 of the inner wall of the second sealing joint 3, and the thread is connected to the second seal. The second compression cover 5 of the joint 3.

[0037] Such as figure 1 As shown, the first sealing joint 2 is threaded with the motor outgoing line 1, and the first sealing joint 2 is provided with a first sealing pad 11 between the motor outgoing lines 1, and the first sealing pad 11 is a metal pad. The first sealing joint 2 is formed in the inner step one 21, and one end of the sealing cushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com