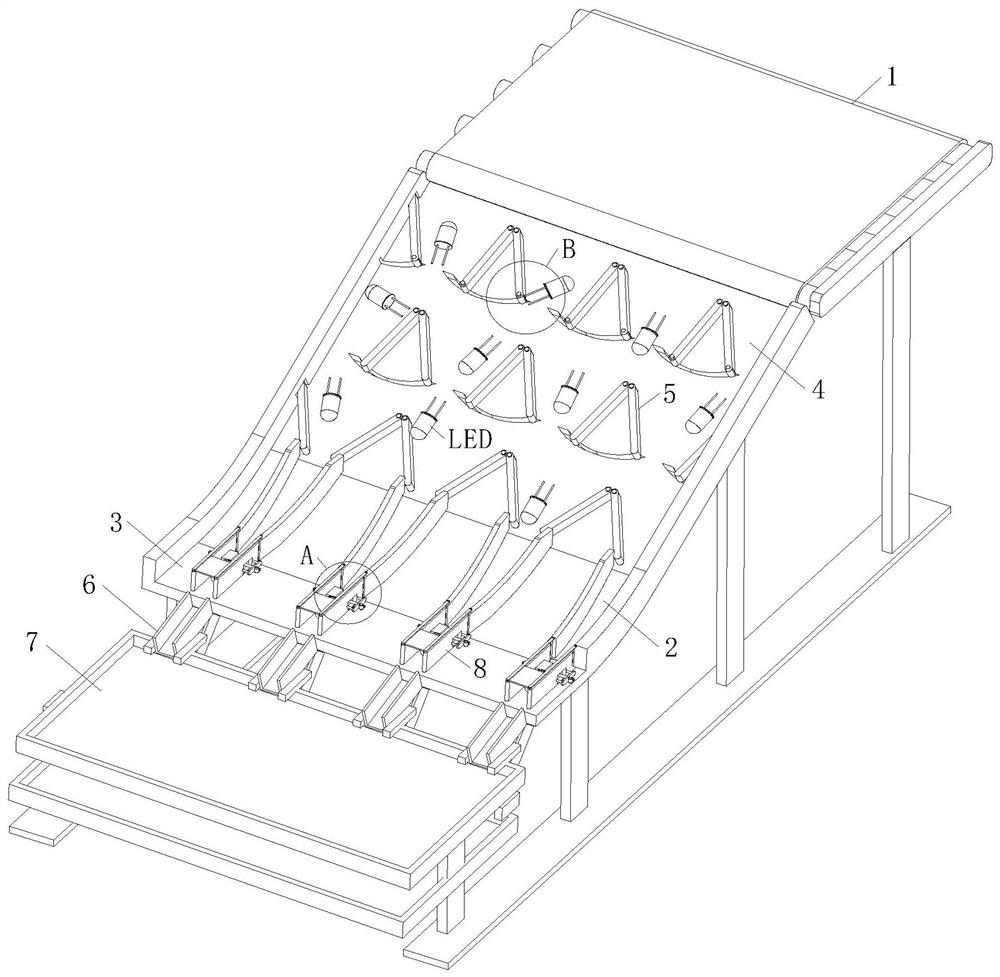

Intelligent light-emitting diode (LED) automatic sorting system

An automatic sorting system and sorting technology, applied in sorting and other directions, can solve the problems of limiting LED sorting efficiency, difficult to match LED production rate, unsolved LED high-speed detection, etc., to achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

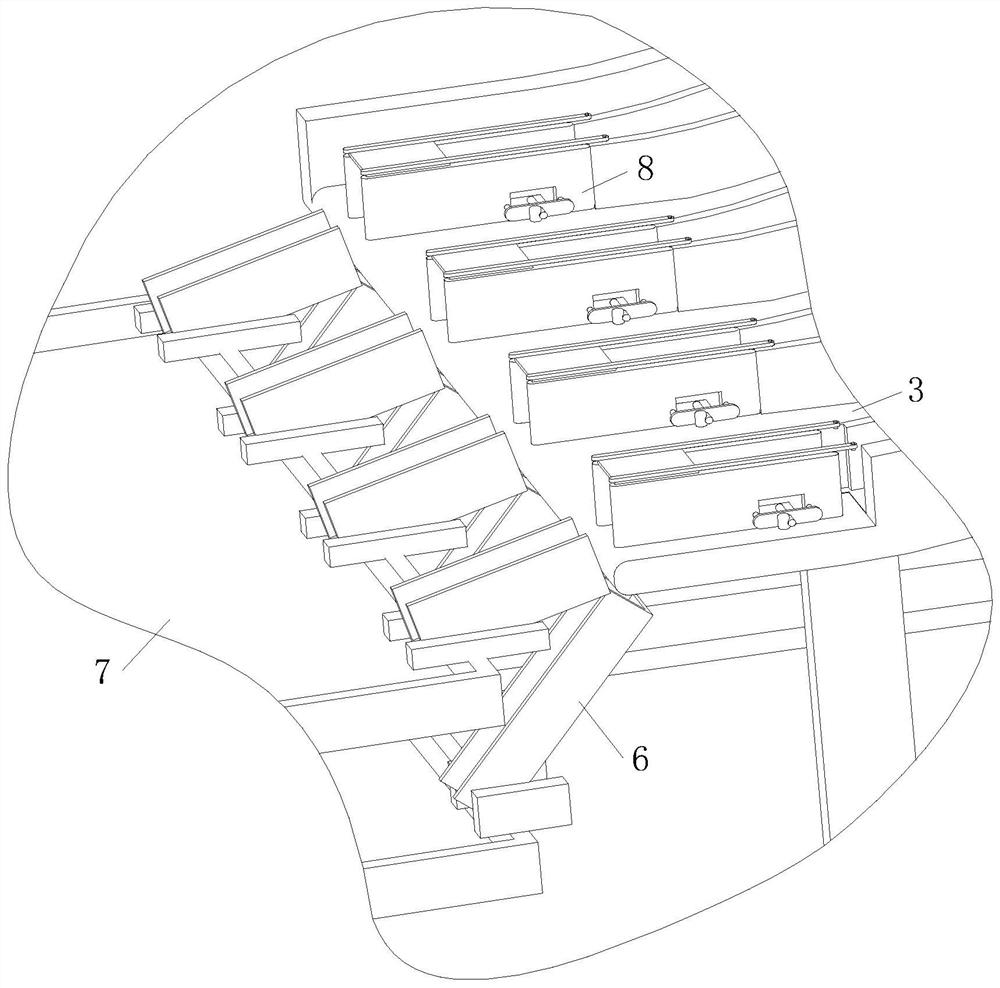

Embodiment approach

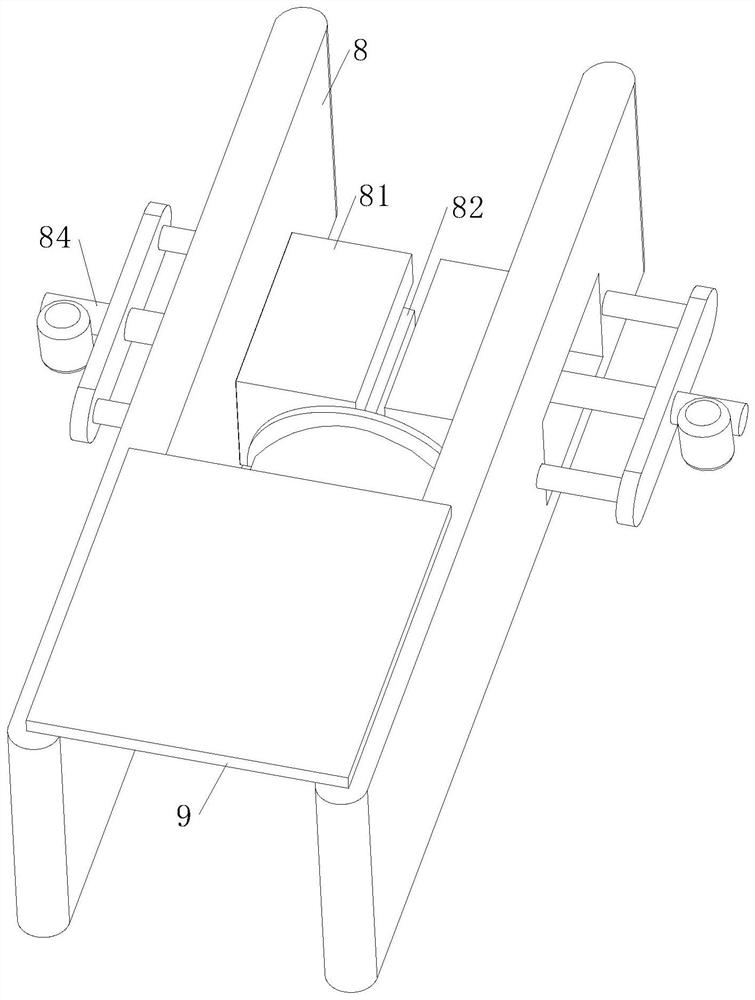

[0035] As an embodiment of the present invention, the detection unit includes a splint 8 and a photometer 9; the splint 8 is perpendicular to the moving direction of the carrier belt 3, and the gap between the splints 8 is used for passing the LED on the carrier belt 3; A pair of telescopic electrode blocks 81 are also installed on the splint 8, and the splint 8 is also provided with a photometer 9 at the end of the LED traveling direction; the photometer 9 is parallel to the surface of the carrier belt 3; during work, the LED is detecting During the process, it needs to be powered on to measure the light parameters, that is, the LED lying flat on the carrier belt 3 needs to keep its electrical connection state stable to ensure the convenience of the measurement process; through the splint set in the detection unit 8. When the LED on the carrier belt 3 enters the detection unit, the controller drives the electrode block 81 in the splint 8 to stretch out, and presses the pins of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com