Machine tool equipment for quickly milling key groove of cylinder

A cylinder and milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of increasing the risk of accidents, the inability to complete keyway processing efficiently, and limiting processing efficiency, so as to save labor intensity and reduce labor The risk of operation, the effect of improving the efficiency of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

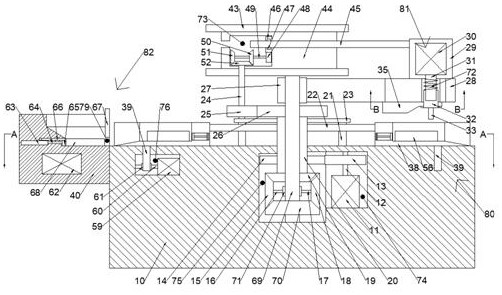

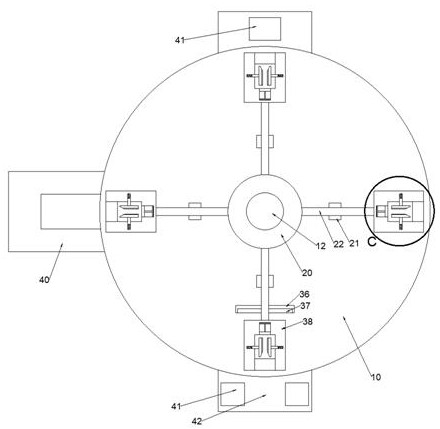

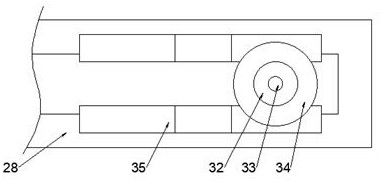

[0018] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] A machine tool for quickly milling a keyway on a cylinder according to the device of the present invention includes a body 10, a power chamber 74 and a rotation chamber 75 are provided in the body 10, a trigger chamber 76 is provided on the left side of the body 10, and a trigger chamber 76 is provided on the left side of the body 10. The left side of 10 is fixed with a fixed body 40, and the fixed body 40 is provided with a feeding chamber 79, and the front and rear sides of the body 10 are respectively fixed with an extension plate 42, and the upper extension plate 42 on the rear side is fixed with a support Column 41, two support columns 41 are fixed on the extension plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com