Plane carcass puncturing device

A carcass and puncture technology, which is applied in the field of rubber tire building, can solve the problems of inability to precisely control the force, easy damage to the steel wire, and the impact of tire quality, and achieve the effect of significant energy saving and stable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the invention is not limited to these embodiments.

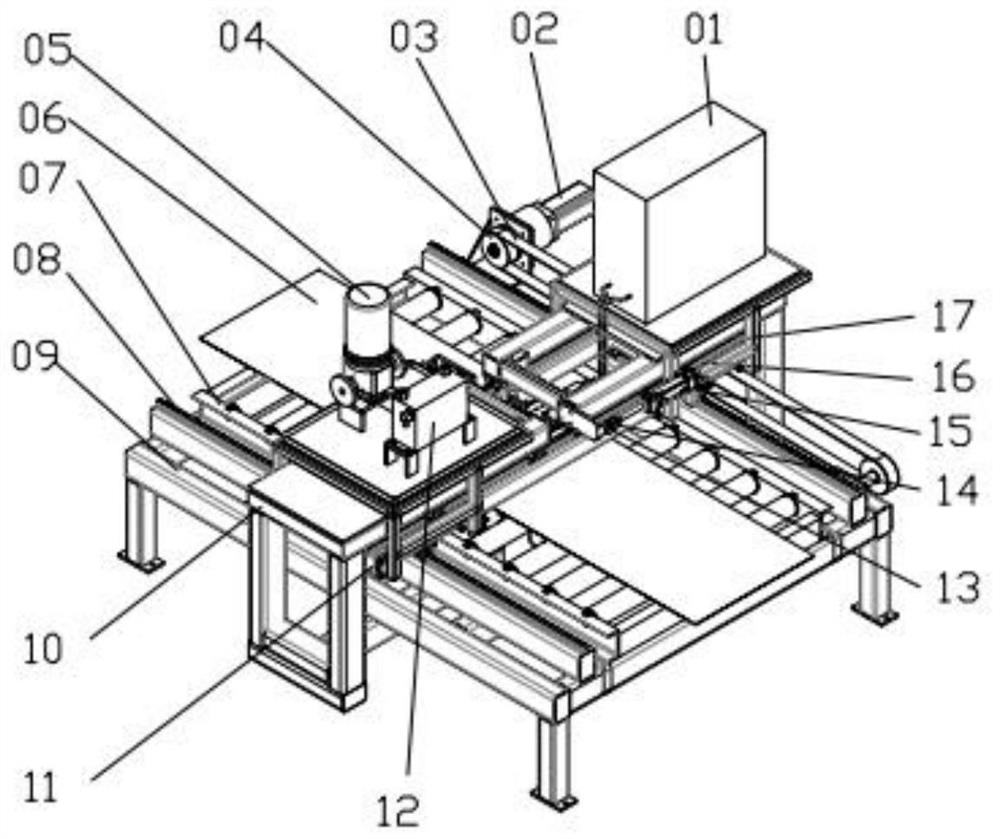

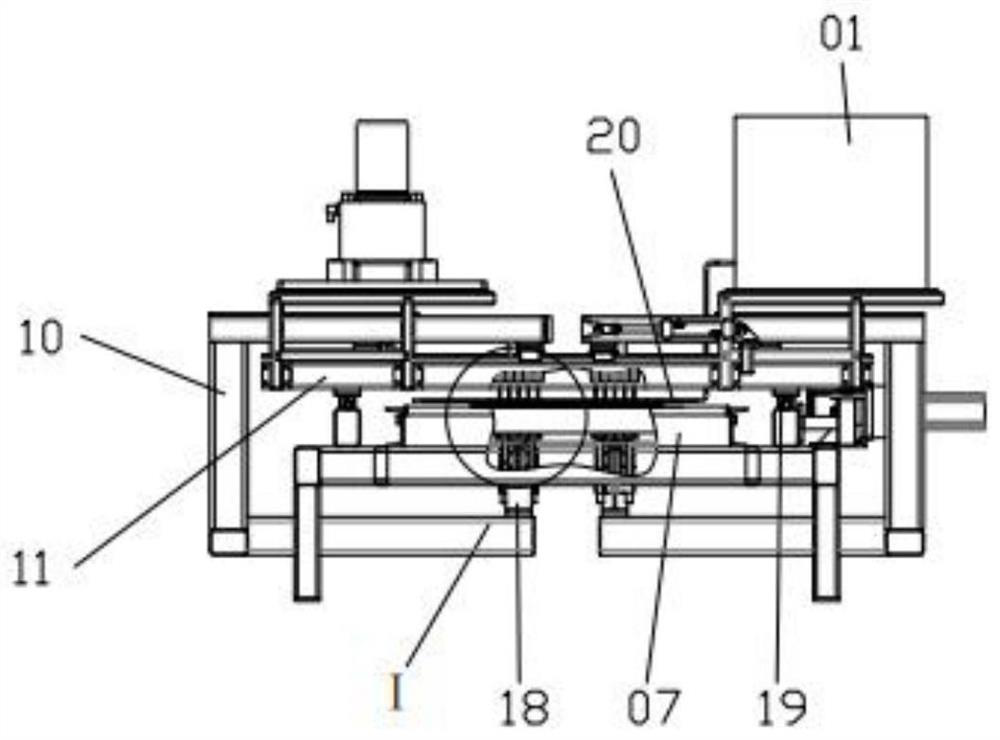

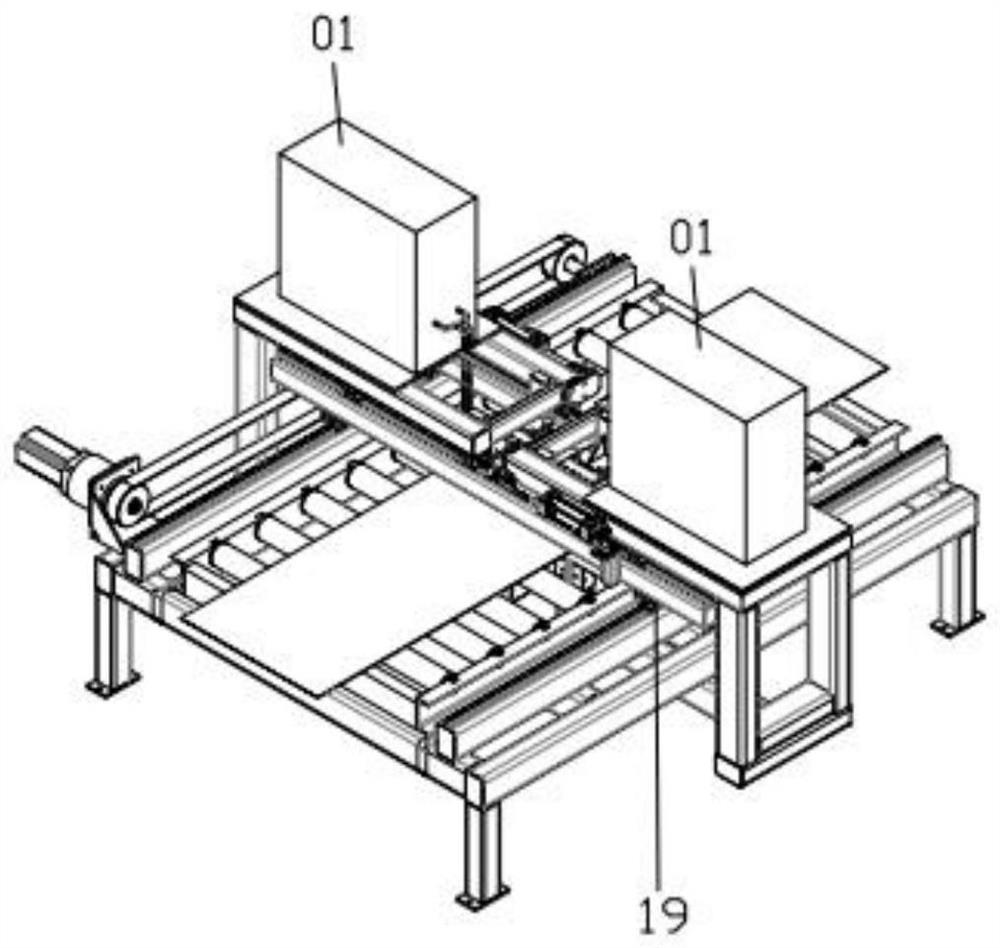

[0025] like Figure 1 to Figure 7 As shown, the present invention provides a plane carcass puncturing device, including a heating mechanism, a longitudinal movement mechanism, a lateral movement mechanism, a carcass stabilizing puncture mechanism, and a frame. The heating mechanism includes a high-frequency heater 01, and the Described longitudinal movement mechanism comprises longitudinal guide rail slider movement mechanism, longitudinal frame 11; Described transverse movement mechanism is positioned on longitudinal frame 11, comprises transverse frame 10, transverse power unit, transverse guide rail 17, transverse slide block 16, and described The carcass stabilizing puncturing mechanism is fixedly connected with the transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com