Vamp sewing device

A shoe upper and sewing technology, which is applied to sewing equipment, sewing machine components, leather product sewing machines, etc., can solve problems such as low production efficiency, complicated shoe upper processing, and easy distraction, and achieve the effect of improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

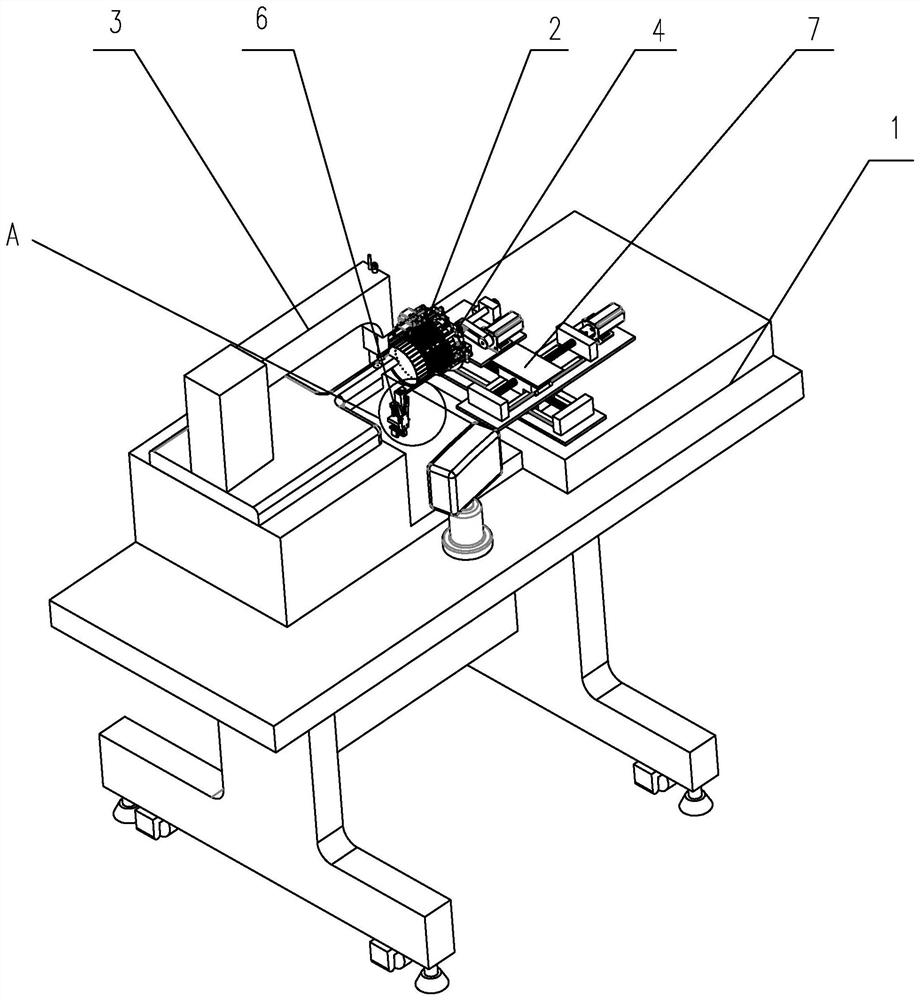

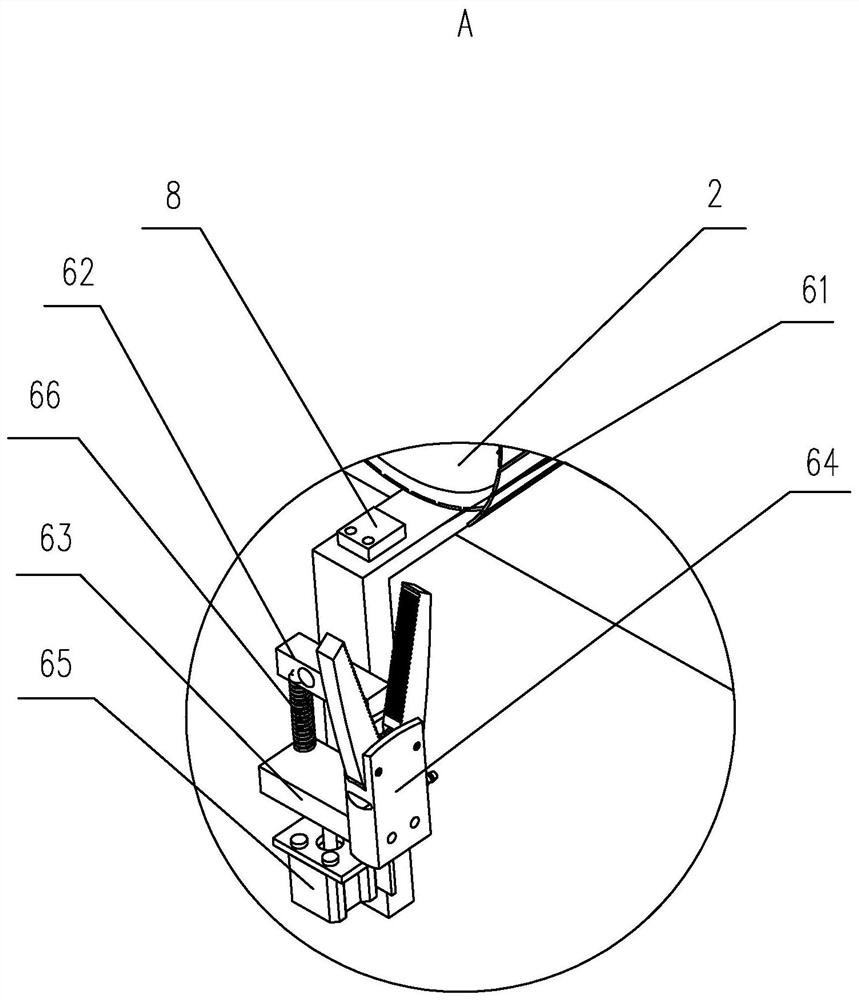

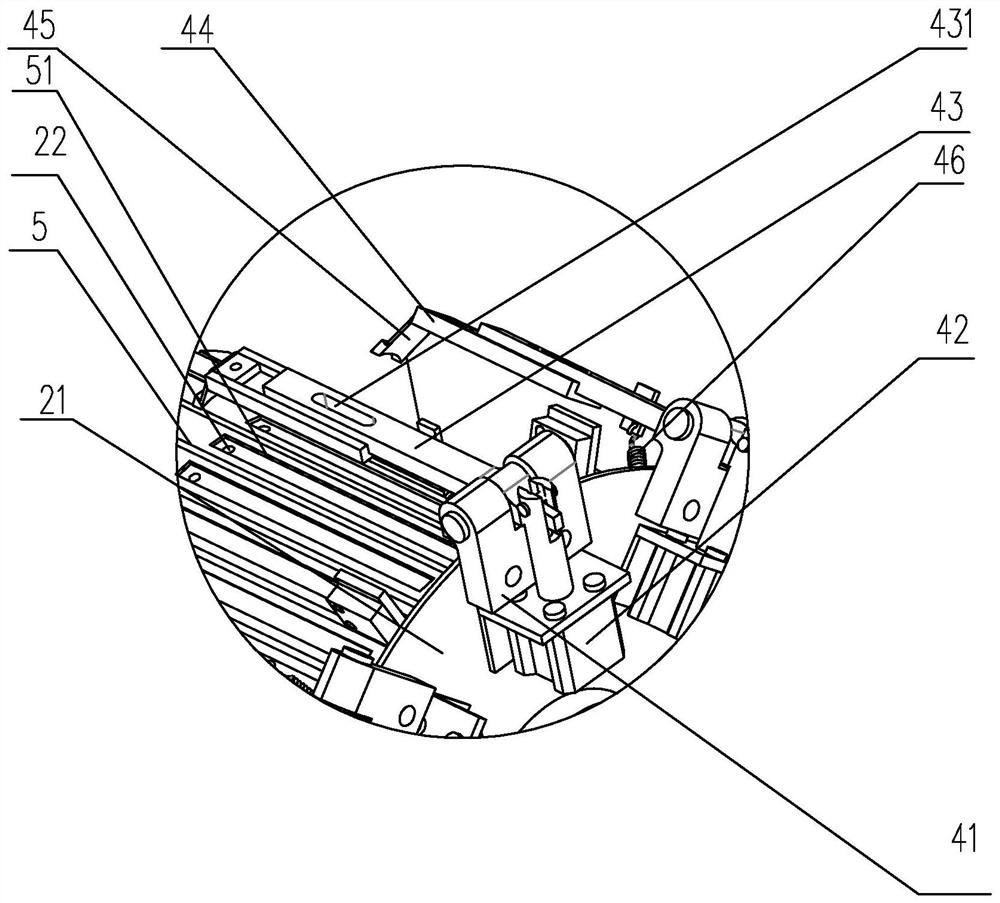

[0029] The embodiment of shoe upper sewing device of the present invention is for example Figure 1 to Figure 5As shown: it includes a frame 1, on which a sewing machine 3 is set, and on the frame 1 is also set an arc-shaped plate 2 for sheathing the vamp and an arc-shaped plate 2 for driving rotation and movement The drive mechanism 7, the arc plate 2 is provided with an edge trimming piece 5 for aligning the collar edge of the back of the shoe and a positioning piece 4 for making the heel lining against the shoe upper, the arc plate 2 Between the sewing machine 3, there is also a tightening member for attaching the vamp to the edge of the arc-shaped plate 2 and tightening it up. The frame 1 is also provided with a line array camera 8 and a console, and the console is connected to the The line scan camera 8, the sewing machine 3 and the driving mechanism 7 are connected in communication. The beneficial effect of such setting is: setting in this way, the neckline position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com