Closing-in installing structure of detachable shutter

A technology for installing structures and louvers, which is applied to building components, building structures, shading screens, etc., can solve problems such as quality defects of curtain wall products, inability to disassemble, and curtain wall damage, so as to ensure the smoothness and integrity of the appearance, save materials and resources, ease of installation and precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

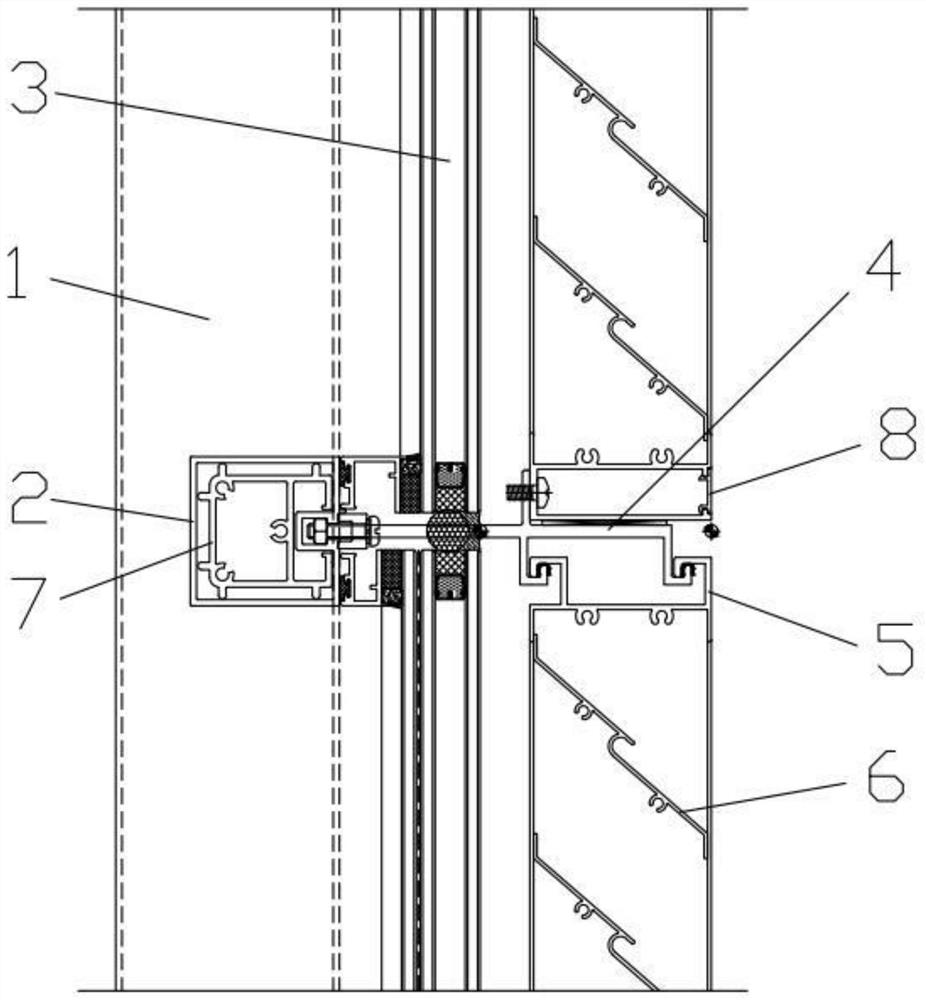

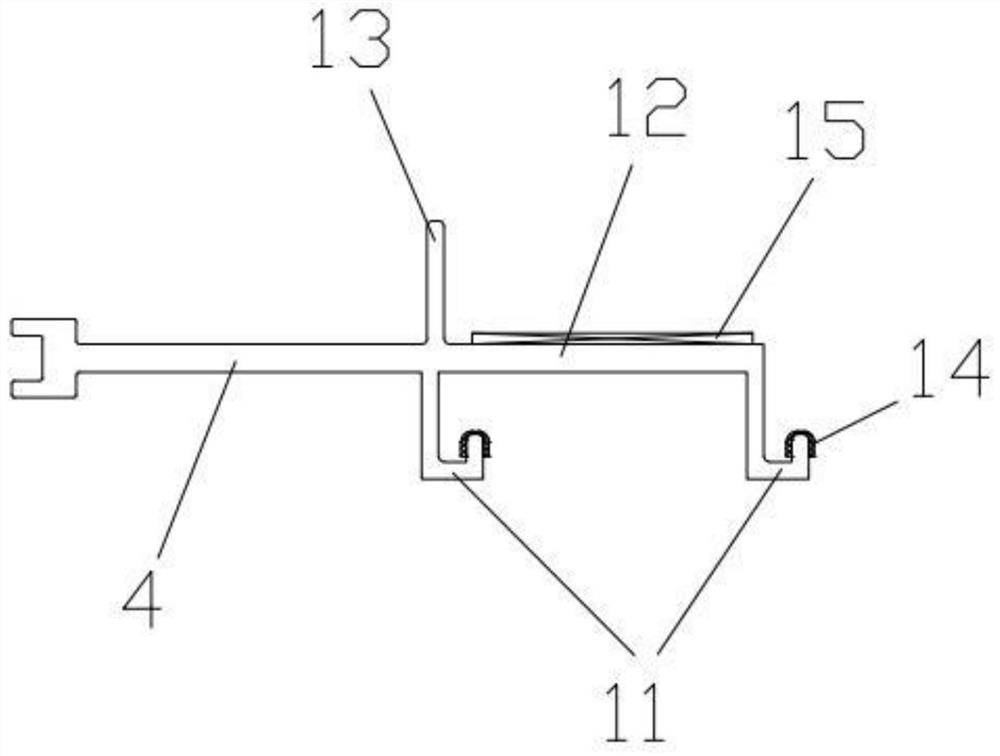

[0016] like Figure 1-2 As shown, a closing installation structure of a detachable louver according to the present invention includes a curtain wall keel, a curtain wall glass 3, a connecting pendant 4 and a louver frame 5. The curtain wall keel is composed of a column 1 and a beam 2, and the beam 2 is provided with a sleeve The core 7 and the sleeve core 7 play a supporting role on the beam 2 to ensure the stability of the beam 2; the curtain wall glass 3 cooperates with the column 1 and the beam 2 through the glass attached frame, and the louver frame 5 is provided with louver blades 6 to form a louver The unit can be processed and formed in the factory first, and directly transported to the site for installation.

[0017] One end of the connecting pendant 4 located inside the room of the curtain wall glass 3 cooperates with the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com