A liquid rocket engine exhaust blowing treatment device and method

A liquid rocket and processing device technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems such as difficult to handle safely, health and safety hazards of operators, etc., and achieve easy replacement, small and compact structure, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the invention will be clearly and completely described below in conjunction with the accompanying drawings.

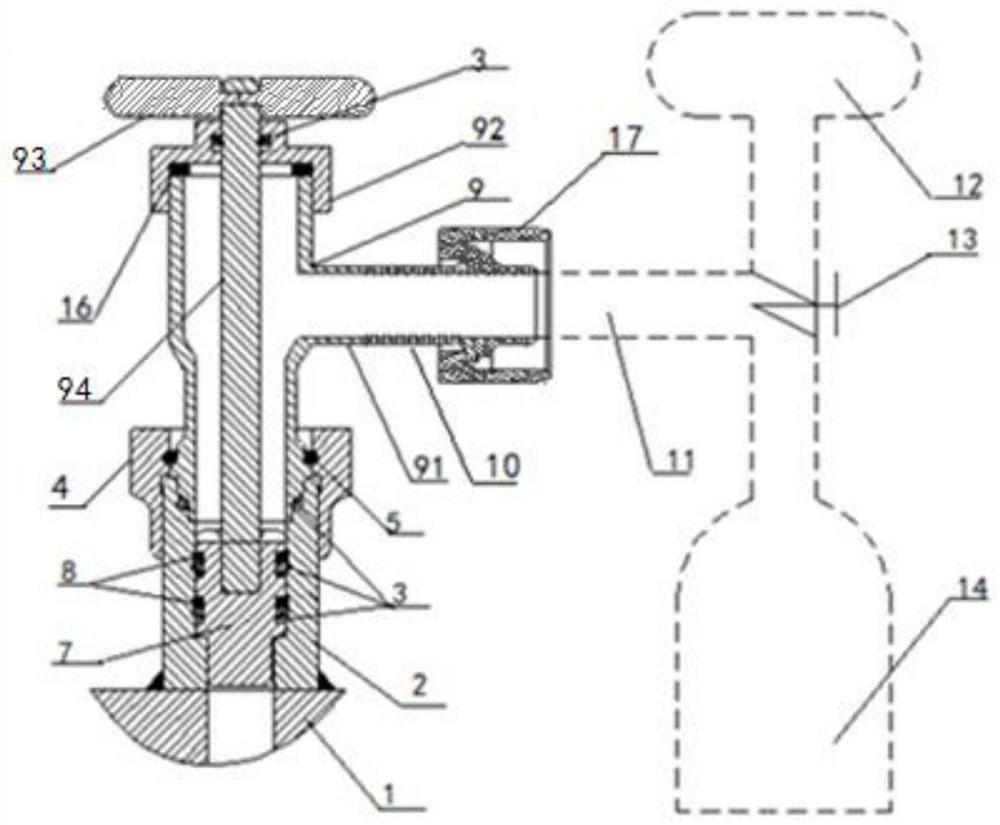

[0044]The invention provides a liquid rocket engine discharge blow-off device, which includes a nozzle 2, a discharge blow-off tool 9, and a recycling blow-off system.

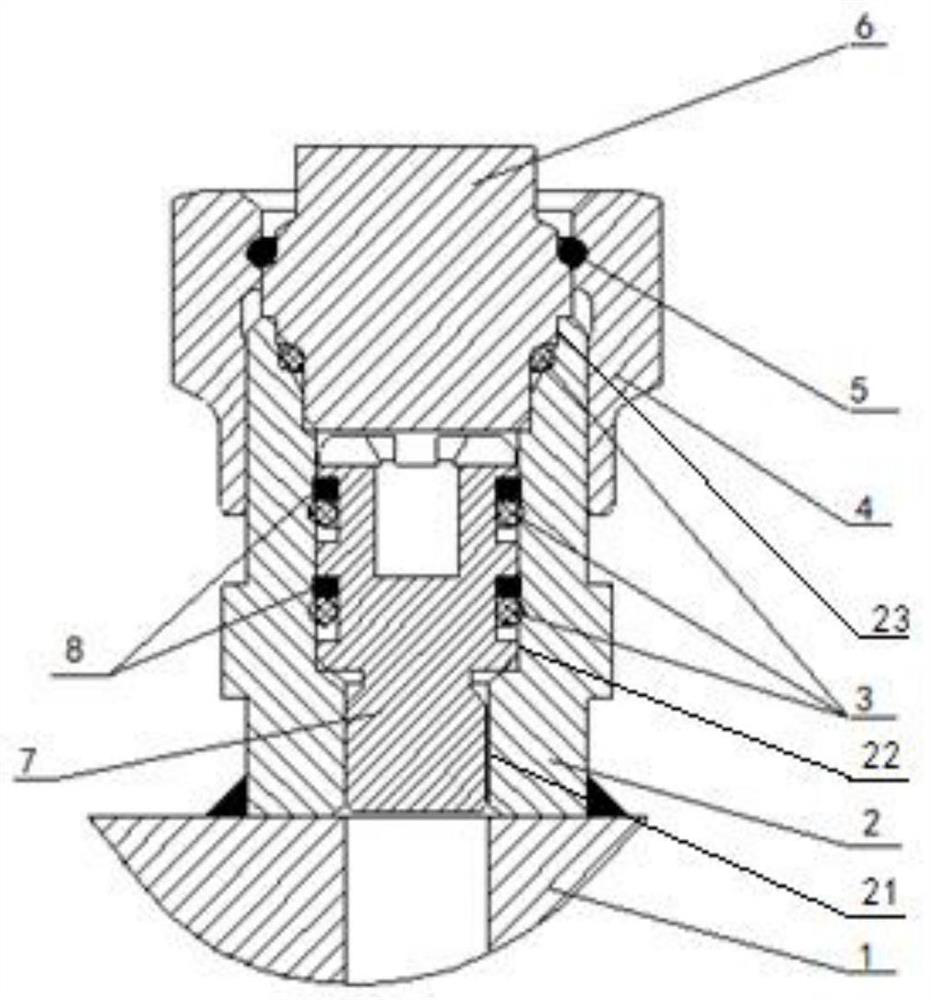

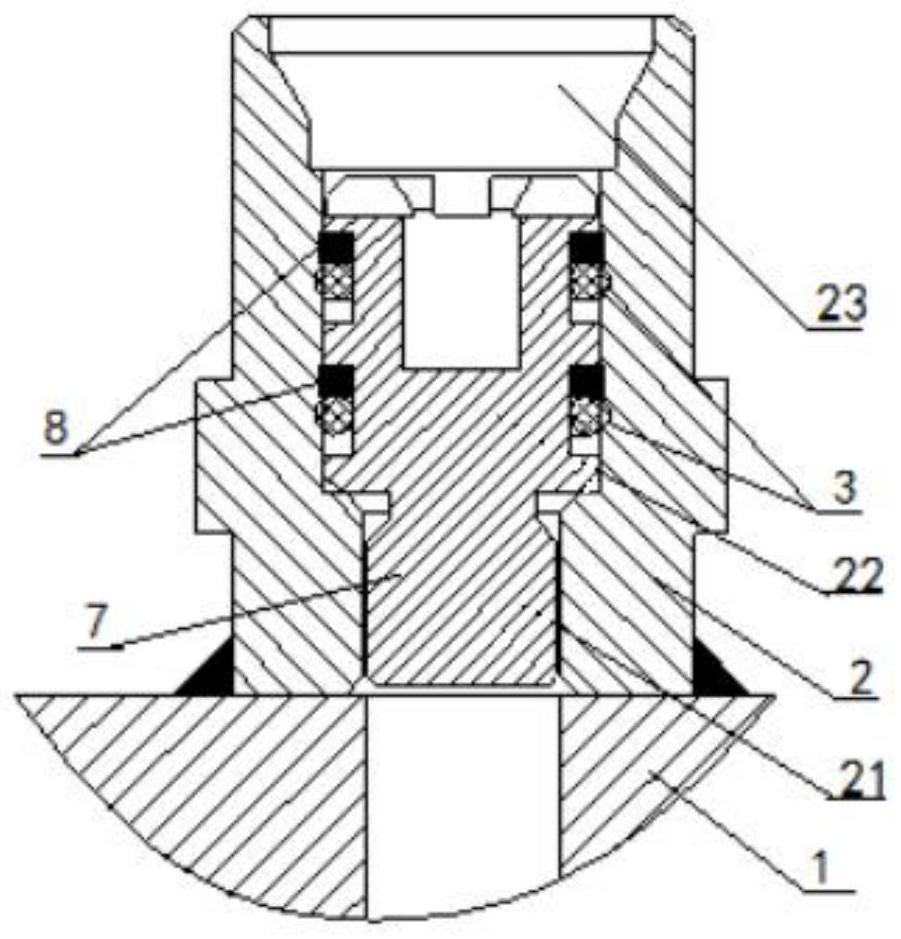

[0045] Such as figure 1 As mentioned above, the nozzle 2 is fixed on the engine housing 1 where it needs to be discharged and blown off. A sealing plug 7 is installed in the nozzle 2. The front end of the sealing plug 7 is threadedly connected to the inner wall of the nozzle 2, and the rear end is provided with a There is an interface; due to the different diameters of the nozzle 2, the sealing plug 7 is composed of two cylinders with different radii, the radius of the rear end is larger than that of the front end, and the sealing plug 7 occupies the interface pipe section 21 and the The straight pipe section 22 and the front end of the sealing plug 7 are connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com