Drying and collecting device and drying and collecting process for bearing maintenance

A collection device and drying technology, which is applied in the direction of drying gas arrangement, drying solid materials, and drying goods processing, etc., can solve the problems of high labor consumption and low work efficiency, and achieve the effect of reducing labor labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The application will be described in further detail below in conjunction with the accompanying drawings.

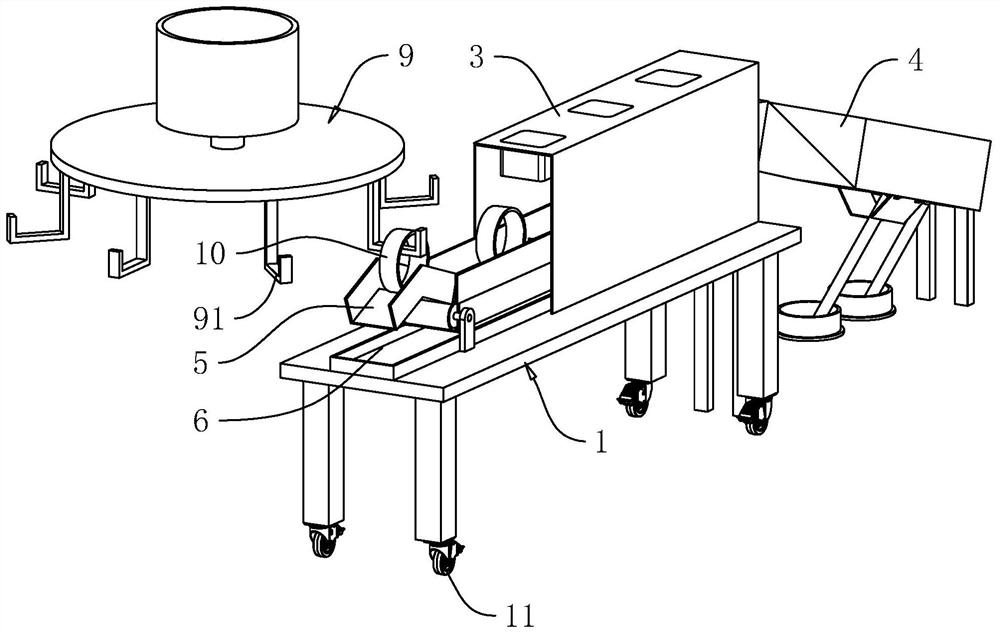

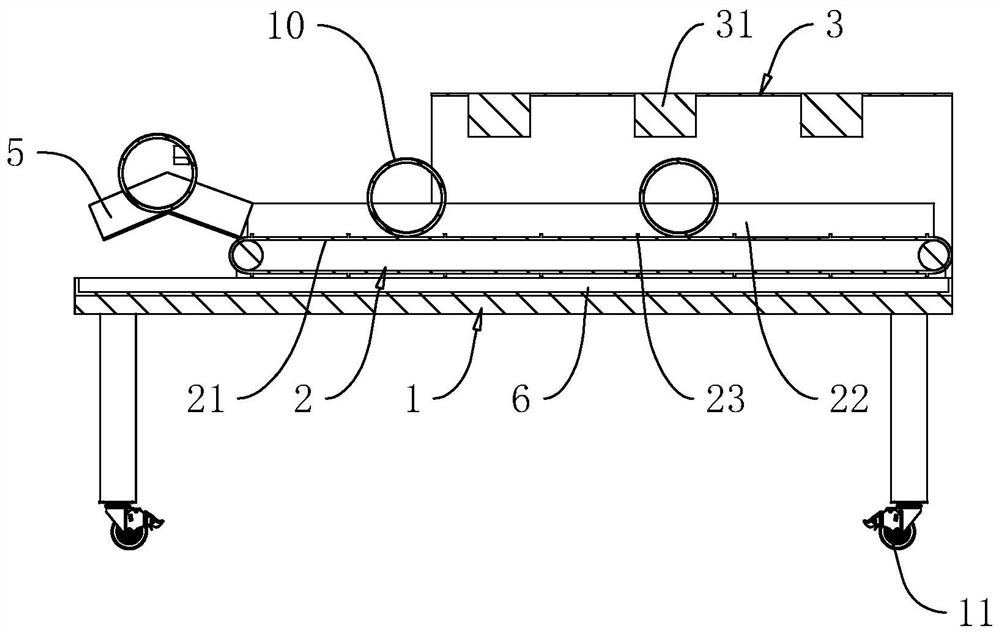

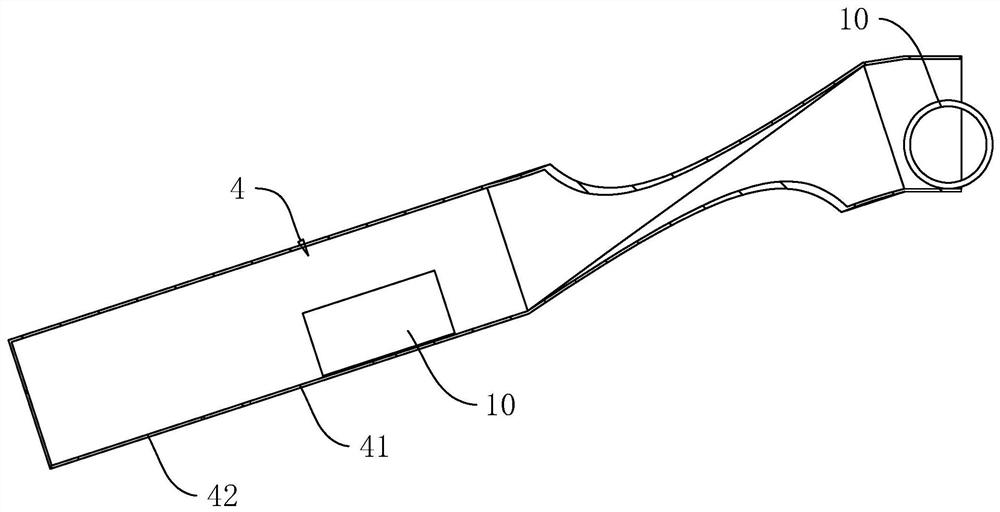

[0043] The embodiment of the present application discloses a dry collection device and a dry collection process for bearing maintenance. refer to figure 1 and figure 2 , a dry collection device for bearing maintenance includes a bottom frame 1, a belt conveyor 2 fixedly mounted on the bottom frame 1 laterally, a drying box 3 covered on the belt conveyor 2, and a belt conveyor The guide slideway 4 at the discharge end of the machine 2, and the collection assembly near the discharge end of the guide slideway 4. The bearing ring 10 is hung on the hook 91 of the rotating hanger 9 for cleaning, and the upper surface of the conveyor belt 21 of the belt conveyor 2 is higher than the height of the lowest part when the bearing ring 10 is hung on the rotating hanger 9. The feeding end of the type conveyor 2 is close to the edge of the rotating rack 9, and the belt convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com