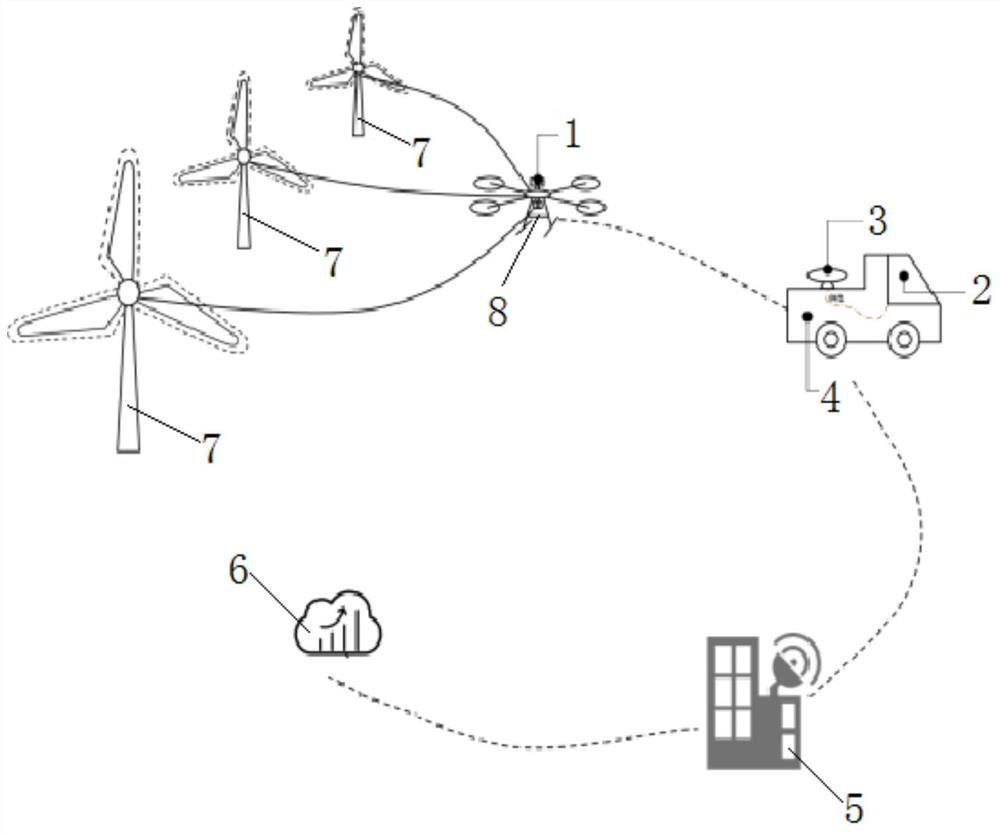

Wind driven generator blade dynamic inspection system and method

A technology of wind turbine and inspection system, applied in the field of wind power generation, can solve the problems of large loss of power generation due to shutdown, high labor intensity of workers, low detection efficiency, etc., so as to avoid energy loss, save manpower, and facilitate moving back and forth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

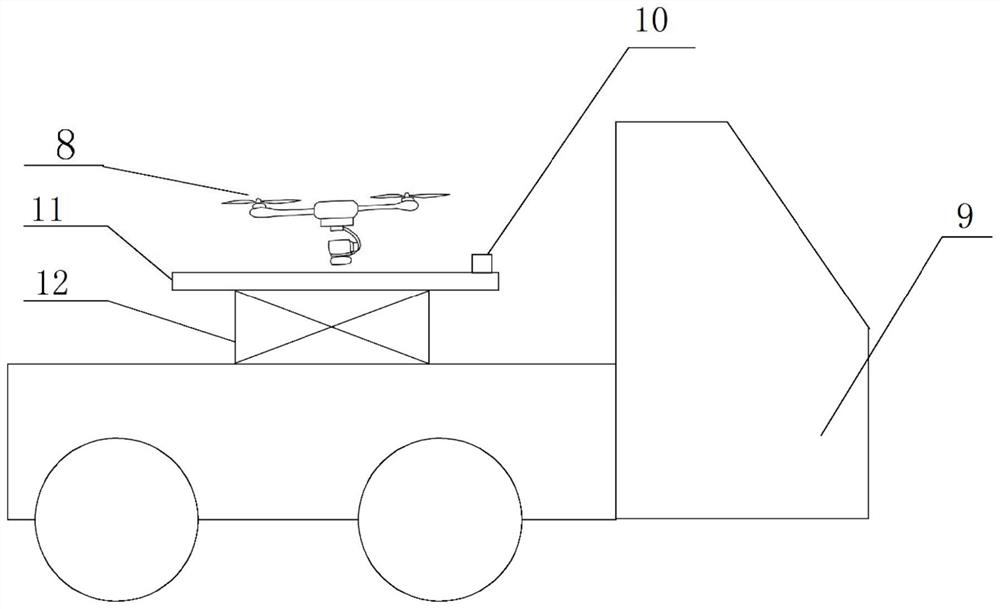

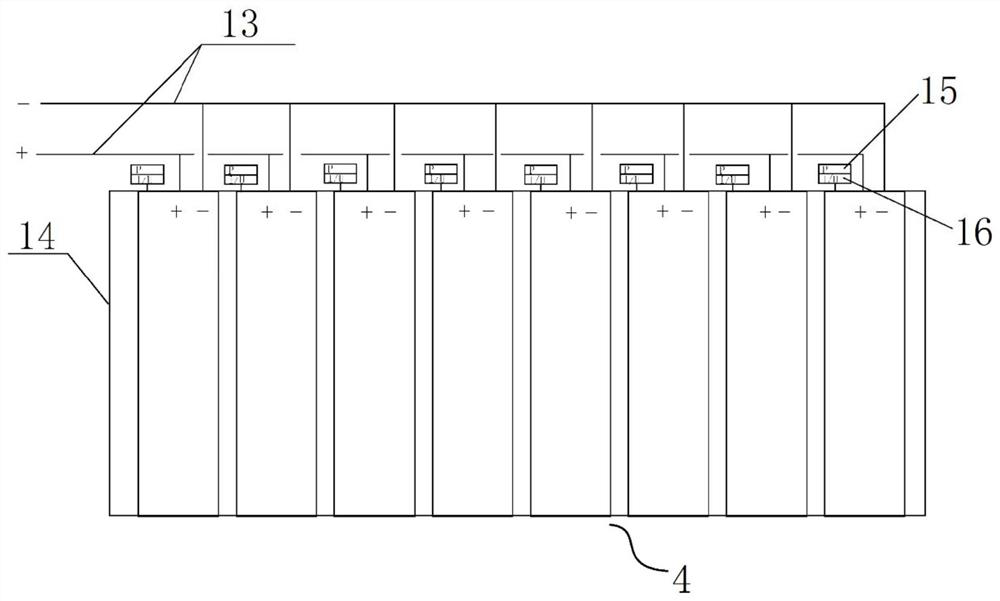

[0056] 1. After the inspection personnel drive the mobile vehicle 9 equipped with the blade dynamic inspection system of the present invention to the vicinity of the wind turbine 7 of the wind turbine that needs to be inspected by the blades, they check the lithium battery power of the UAV through the UAV battery compartment device 4, Whether the battery is faulty, and from the unmanned aerial vehicle battery compartment device 4, select the lithium battery that has been charged without failure and pack it into the unmanned aerial vehicle 8 placed on the unmanned aerial vehicle take-off and landing device 3 .

[0057] 2. The inspection personnel control the UAV take-off and landing device 3 to rise by operating the UAV control system 2 . It is also possible to operate the lifting platform controller 10 of the unmanned aerial vehicle landing device 3 which is provided separately to control the platform to rise.

[0058] 3. The inspectors prepare inspection tasks by operating th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap