Single-row walking type garlic combine harvester

A combine harvester, walk-behind technology, applied to digging harvesters, harvesters, excavators, etc., can solve problems affecting the best harvest time, farmers' economic losses, and long-term garlic harvesting, so as to facilitate follow-up Storage and processing, good harvest, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

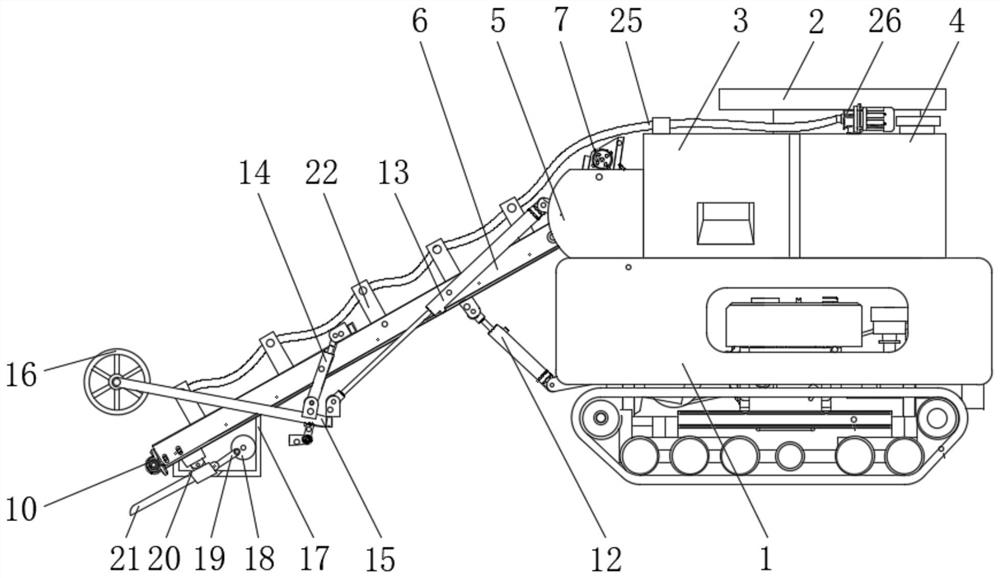

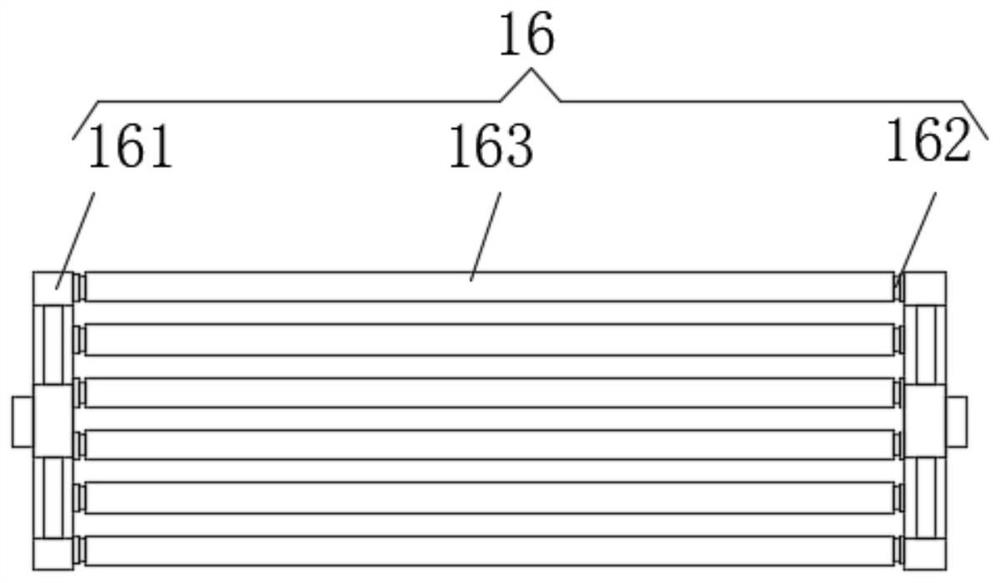

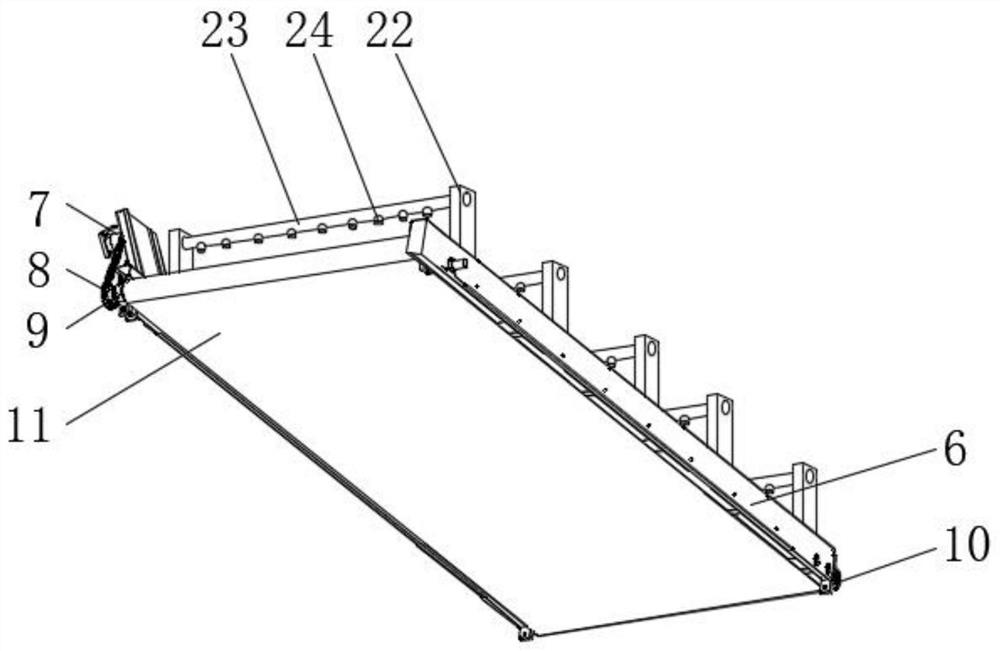

[0023] Such as Figure 1-3 As shown, the present invention provides a technical solution: a single-row walk-behind garlic combine harvester, comprising a harvester body 1, the upper surface of the harvester body 1 is provided with a control chamber 2, and the upper surface of the harvester body 1 is in contact with the storage The lower surface of the feed bin 3 and the water storage bin 4 are fixedly connected, the left side of the inner wall of the storage bin 3 is fixedly connected with the right side of the feed inlet 5, and the front and back sides of the feed inlet 5 inner wall are connected to the first rotating shaft 9 through bearings. The two ends are clamped, and the surface of the first rotating shaft 9 is clamped with the front and the back of the cleaning frame 6 inner wall through two bearings, and the front and the back of the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com