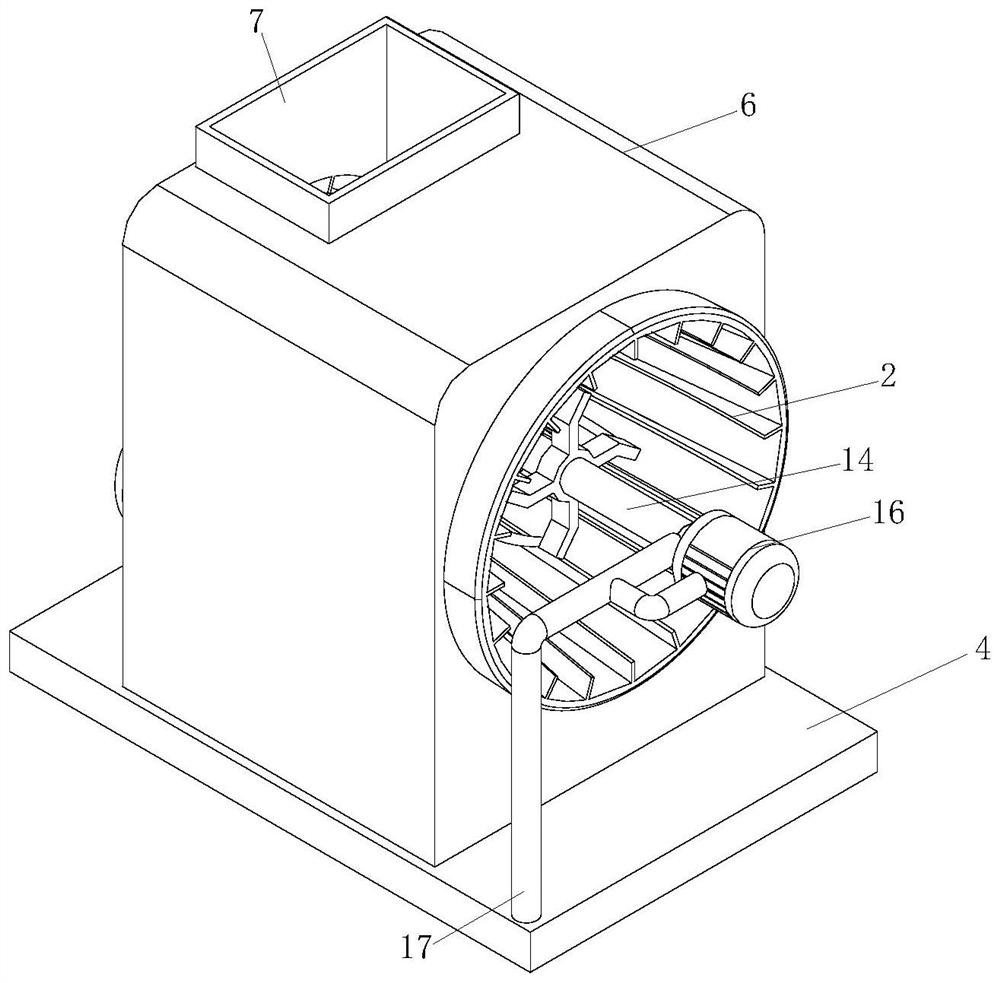

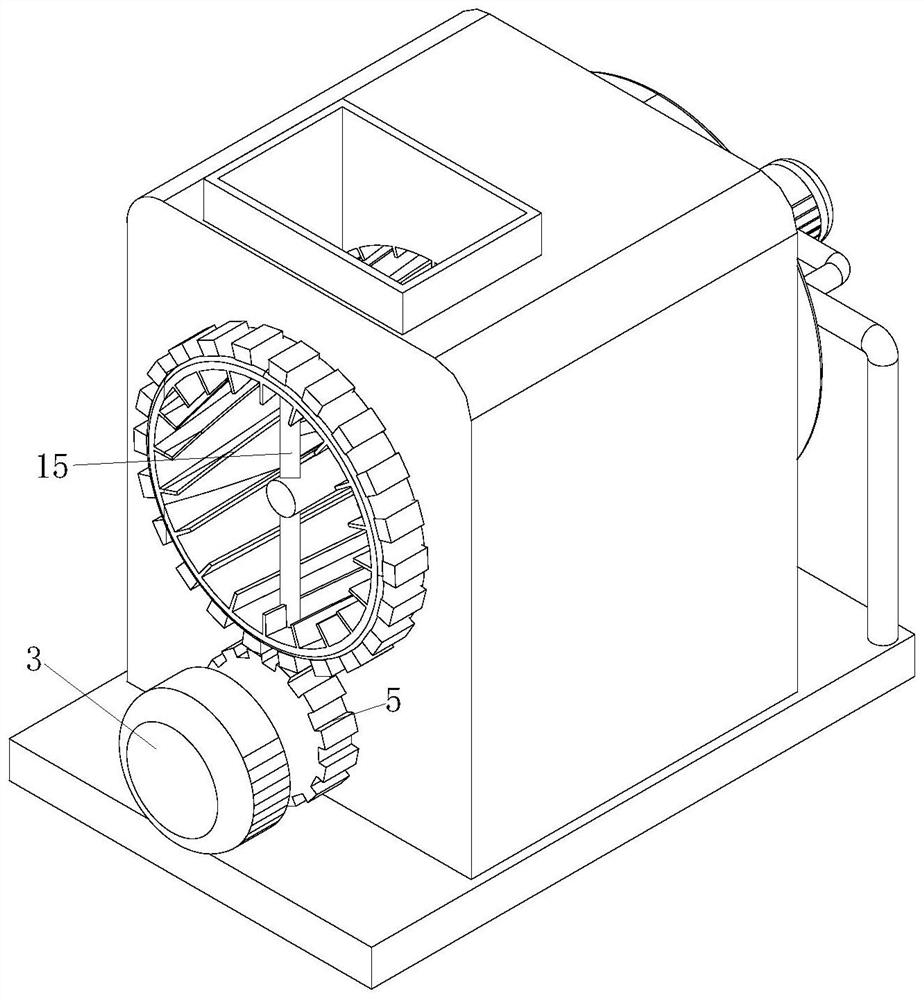

Puffed food processing system

A technology of puffed food and processing system, applied in the field of puffed food processing, can solve the problems of heavy taste of puffed food, uneven mixing of seasoning and puffed food, etc., and achieve the effect of reducing power requirements and reducing the degree of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

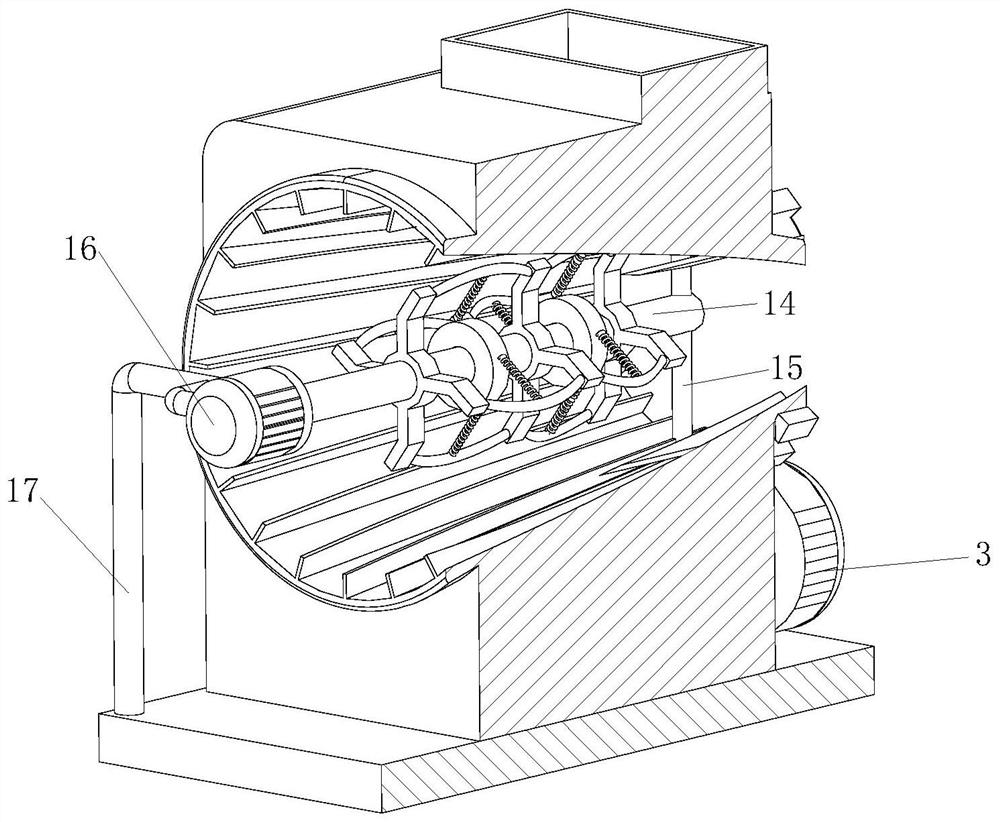

[0026] As an embodiment of the present invention, the distance between two adjacent groups of breaking leaves 18 gradually increases from left to right; the two adjacent groups of breaking leaves 18 are correspondingly fixedly connected with soft columnar capsules 19 The soft column bag 19 is inflated in an arc shape after being inflated; the soft column bag 19 can be used to straighten the puffed food accumulated at the bottom; during work, the puffed food is easy to produce puffed food when it is dropped from the entrance of the mixing shell 1 If they are piled up together, the puffed food at the bottom will not be sprinkled with seasoning; in the present invention, the soft column capsules 19 are fixedly connected to the two groups of breaking leaves 18, and the rotation of the breaking leaves 18 drives the soft column capsules 19 to rotate. During the rotation of the soft column capsule 19, if it touches the piled up puffed food, it will gently flatten the puffed food; this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com