Enveloping type motor rotor purging dust removal device

A motor rotor and dust removal device technology, applied in the direction of smoke removal, cleaning methods and tools, chemical instruments and methods, etc., can solve the problem of increasing the cost of motor rotor cleaning equipment, difficulty in ensuring the effect of motor rotor dust removal, and poor working environment in maintenance workshops and other problems to achieve the effect of avoiding dust removal blind spots, improving efficiency and quality, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

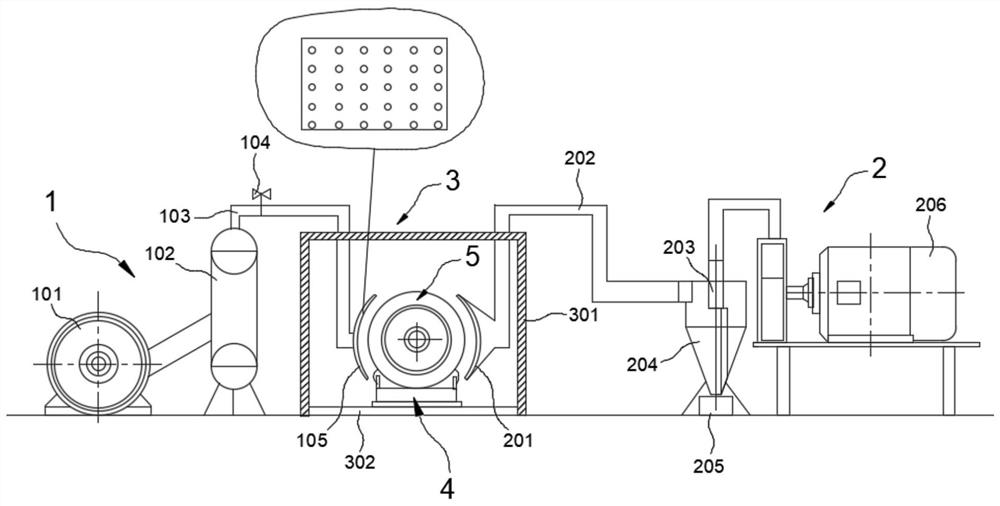

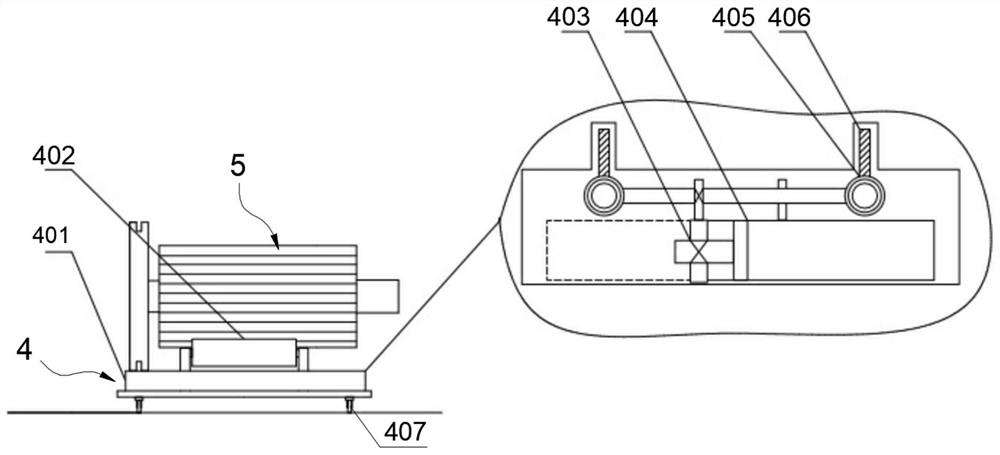

[0040] see figure 1 , 2 , The enveloping motor rotor blowing and dust removal device in the preferred embodiment of the present invention includes a blowing assembly 1 , an exhaust assembly 2 , a dust removal cabinet 3 , and a motor carrying mechanism 4 . Among them, the dust removal cabinet 3 is preferably arranged in the maintenance workshop, and is used to form a closed space for placing the motor rotor 5 to be purged; Operation, the dust in the motor rotor is blown out, and then the air containing a large amount of dust in the dust removal cabinet 3 is extracted by the exhaust assembly 2 until the blowing and dust removal operation of the motor rotor 5 is completed.

[0041] Specifically, the dust removal cabinet 3 in the preferred embodiment includes a cabinet body 301 , and the bottom of the cabinet body 301 is fixedly arranged to form a closed space where the motor rotor 5 can be placed. Simultaneously, in order to realize putting in and taking out of the motor rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com