Large-diameter seamless tube core rod rapid mounting device and using method

A technology of seamless pipe mandrels and installation devices, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., and can solve problems such as time-consuming, high work intensity, and reduced connection efficiency of mandrels and mandrels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

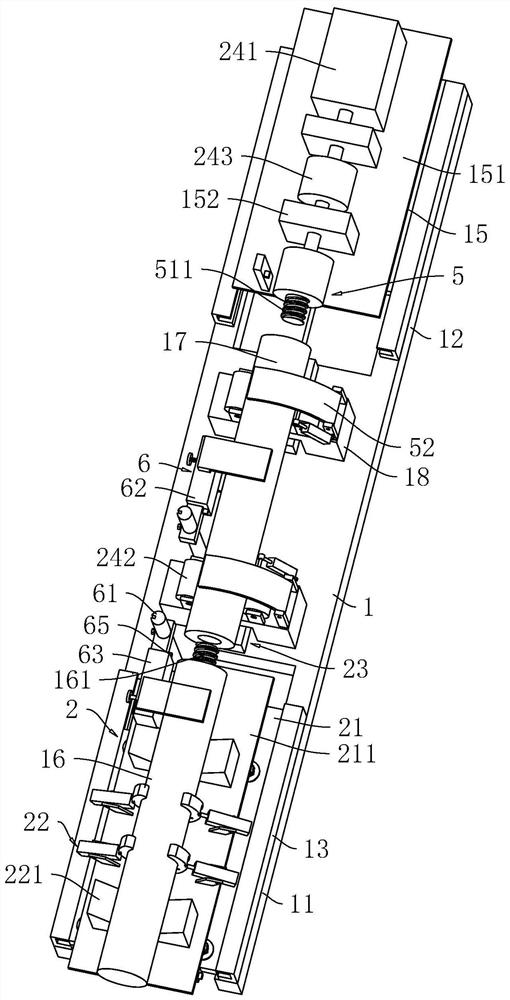

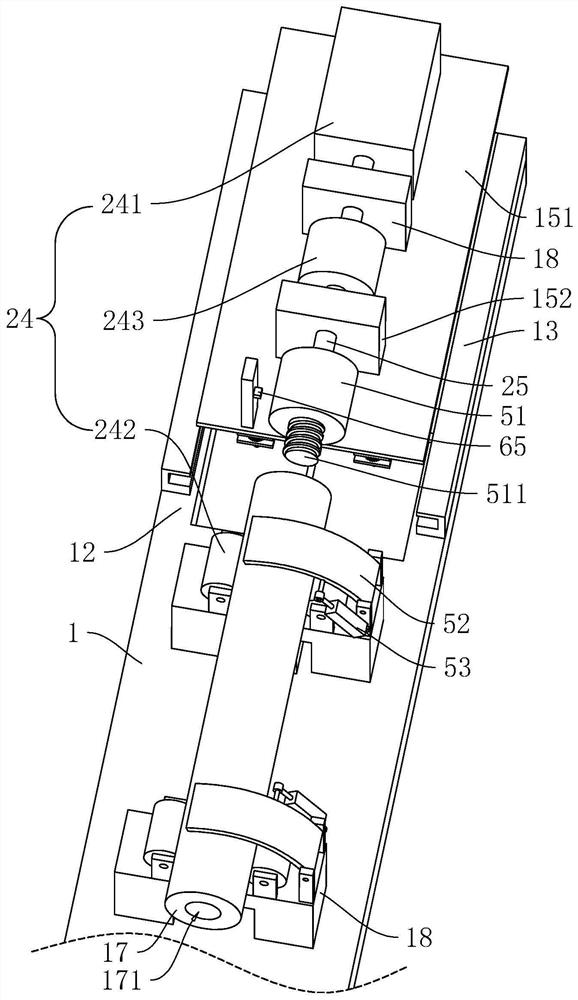

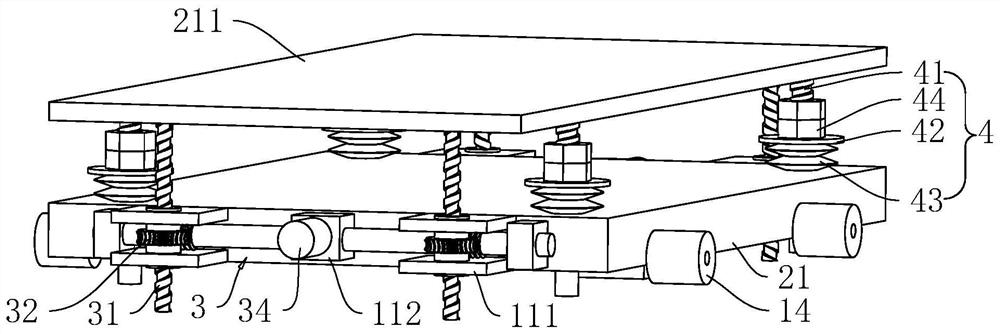

[0063] 1-7 will be described in further detail below in conjunction with the accompanying drawings.

[0064] The embodiment of the present application discloses a rapid installation device for a mandrel rod of a large-diameter seamless pipe.

[0065] refer to figure 1 and figure 2 , The large-diameter seamless pipe mandrel rapid installation device includes a base 1, and the base 1 is provided with an installation system 2. The installation system 2 includes a first sliding seat 21, a clamping mechanism 22, a moving mechanism 23, and a driving mechanism 24.

[0066] refer to figure 1 and figure 2 A first support seat 11 and a second support seat 12 are respectively integrally provided on both ends of the base 1 in the length direction, and two first support seats 11 and second support seats 12 are arranged at intervals along the width direction of the base 1, and at the same time The upper surfaces of the first supporting seat 11 , the second supporting seat 12 and the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap