Multi-head electric servo pressing device

An electric servo and multi-head technology, applied in the field of pressing and forming, can solve problems such as complicated and cumbersome operations, and achieve the effect of improving pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

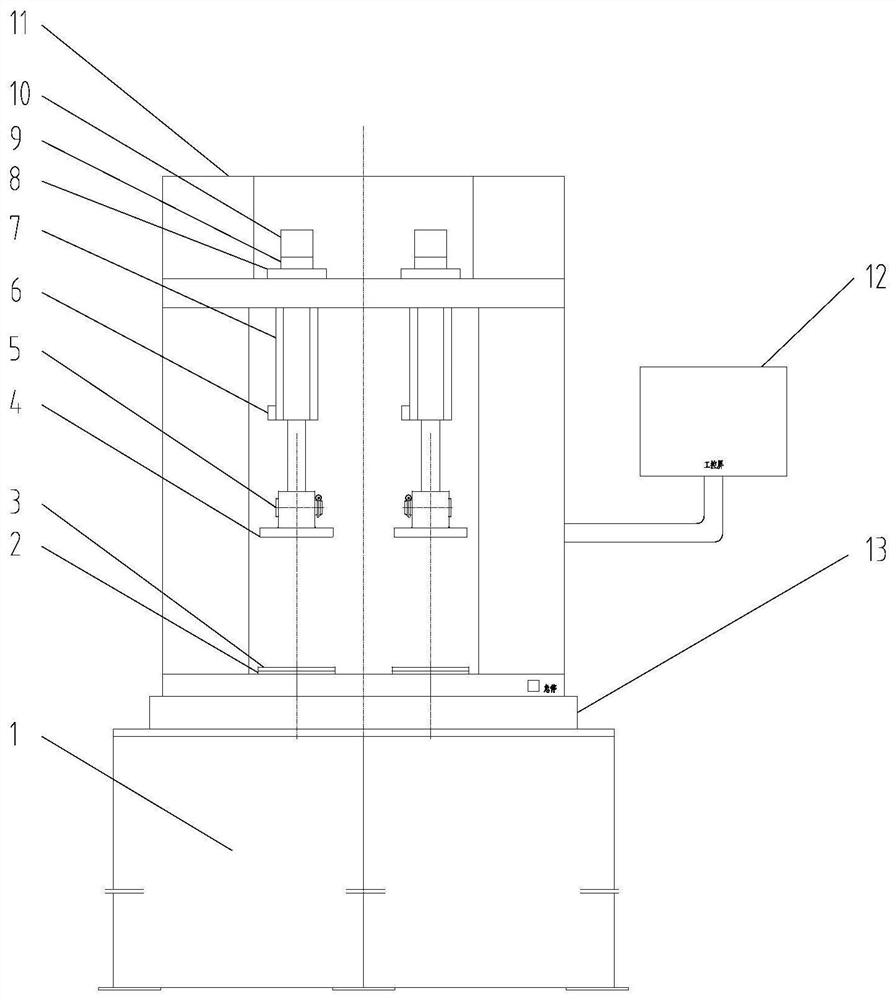

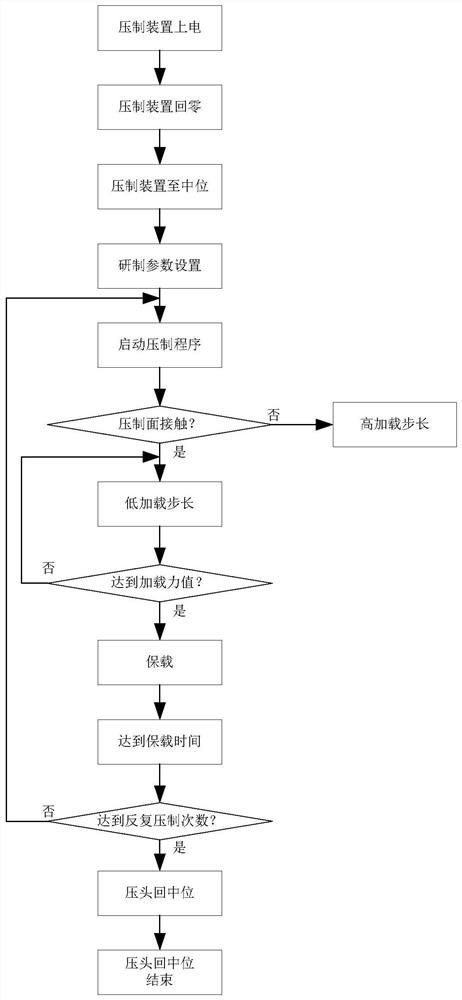

[0039] The invention relates to a multi-head electric servo pressing device, which has multiple stations, including:

[0040] - controller 1, which includes a motion controller and a servo drive, integrated in the cabinet of the pressing device;

[0041] - load-bearing frame 11, located above the controller 1 for bearing;

[0042] - press machine, its number corresponds to the number of stations, used to press the workpiece, on which a laser displacement sensor 6 is arranged to detect the displacement value generated during the pressing process of the workpiece;

[0043] -loading platform 3, the number of which corresponds to the number of stations, and is set towards the pressure head 4 in the pressing machine, for placing the workpiece to be pressed;

[0044] - The force sensor 2 is fixed to the bottom of the load-bearing frame 11 by threads, and a loading platform 3 is arranged on it to detect the axial force carried by the workpiece to be pressed thereon;

[0045] - The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com