Tensile pressure testing machine for batch pressing and method for realizing batch pressing of workpieces

A tension-compression and testing machine technology, applied in the direction of applying stable tension/compression to test the strength of materials, can solve the problems of increasing the tension-compression universal testing machine, unable to meet production needs, not a solution, etc., to achieve good application value and The effect of promoting value, saving money, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

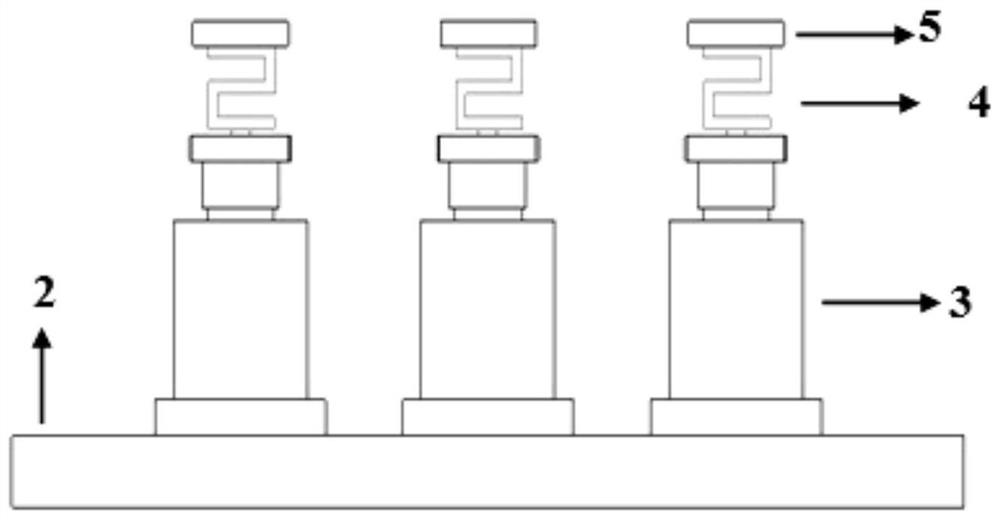

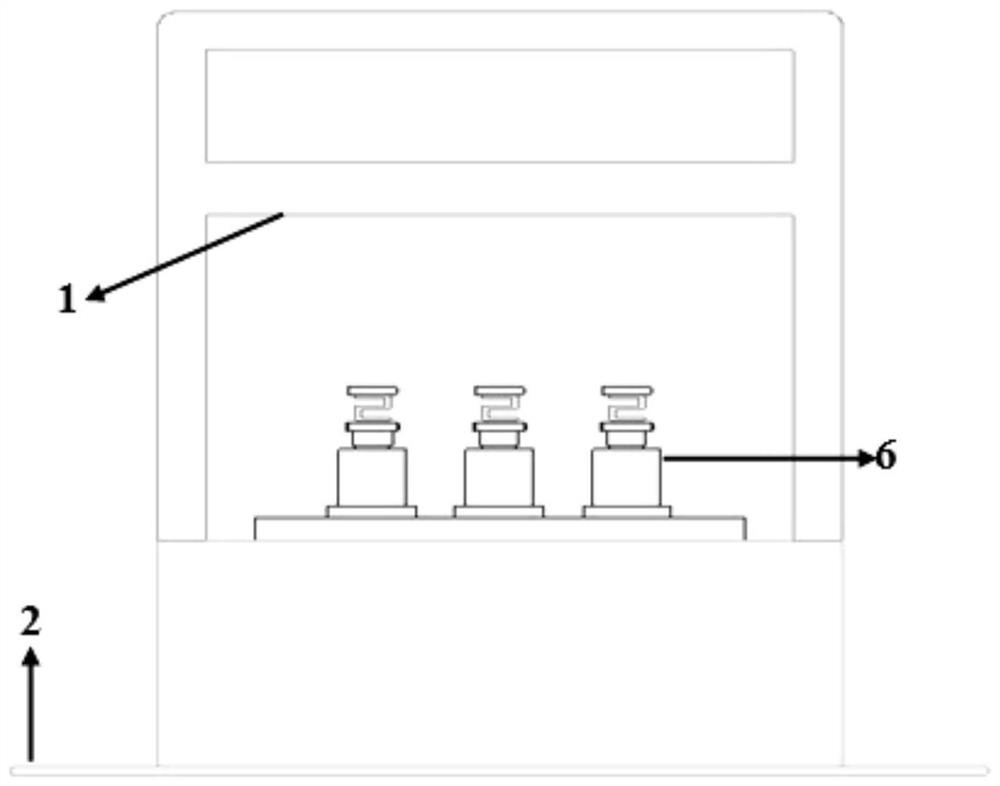

[0032] From figure 1 and figure 2 It can be seen that the tension and pressure testing machine of this embodiment mainly includes an upper beam 1, a base 2, a force value control unit 6 fixed on the base 2, a force value control system and a hydraulic control system; Multiple groups of force value control units 6 are installed on the base 2 of the machine (taking 3 groups as an example), and each group of force value control units 6 includes a hydraulic pump 3 and a force sensor 4 arranged on the jack shaft of the hydraulic pump; On the base 2, the top of the force sensor 4 is used to fix the workpiece to be pressed; in this embodiment, the force sensor 4 is a pressure force sensor, which is fixed on the top shaft of a small hydraulic pump. Each group of small hydraulic pumps and its corresponding pressure force sensor, force control system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com