Pipe-shaped part profiling technology

A part and tubular technology, which is applied in the field of pipe forming process, can solve the problems of large springback, small diameter and high strength, and achieve the effects of complete shape, improved accuracy and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of tubular part pressing process, concrete steps are as follows:

[0023] (1) Connect the upper mold and lower mold of the mold with the press, put the plate to be formed into the lower mold of the mold, and extrude the plate into two semi-circular arc profiles through the cooperation of the press and the mold mechanism ;

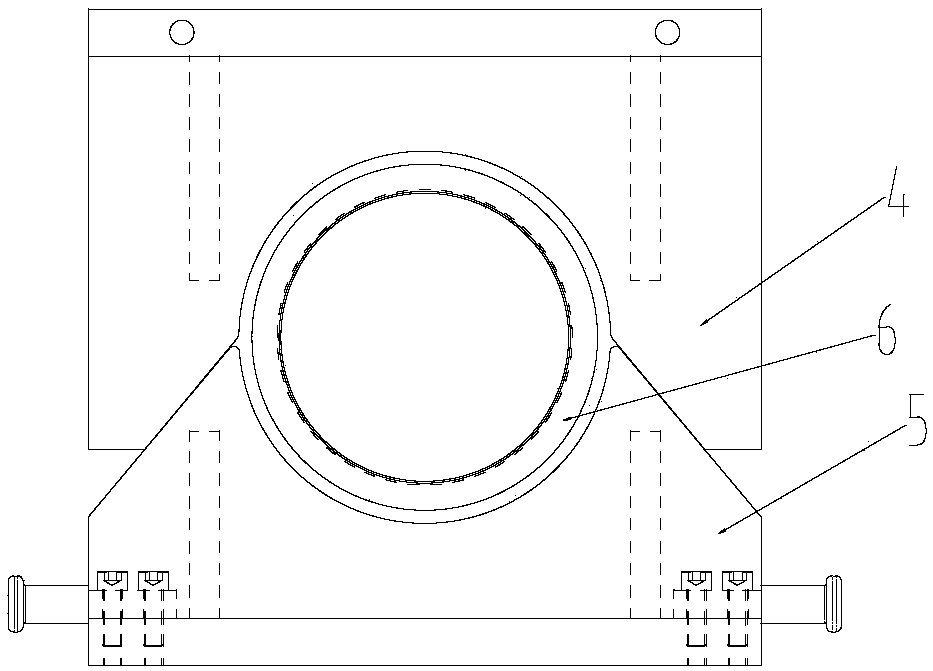

[0024] (2) Replace the mold mechanism of the press, put the two half-arc profiles that have been formed into the lower mold of the replaced mold to form a whole tubular section, insert the mandrel in the middle, and close the upper and lower molds , press extrusion molding;

[0025] (3) Stop the press, slightly open the upper mold of the mold and take out the mandrel;

[0026] (4) Clamp the mold again, press the extrusion machine, and then weld the joints of the tubular profiles.

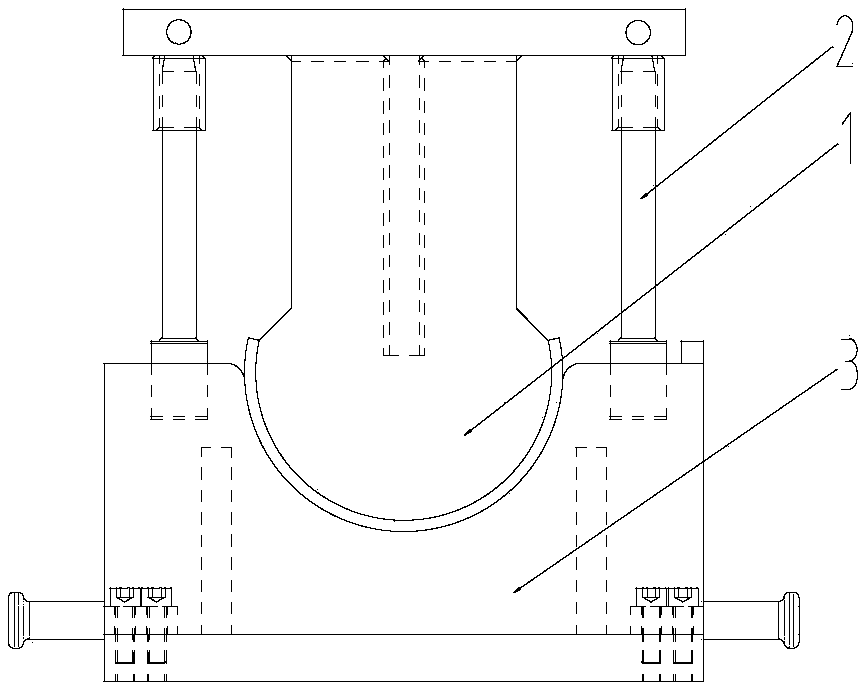

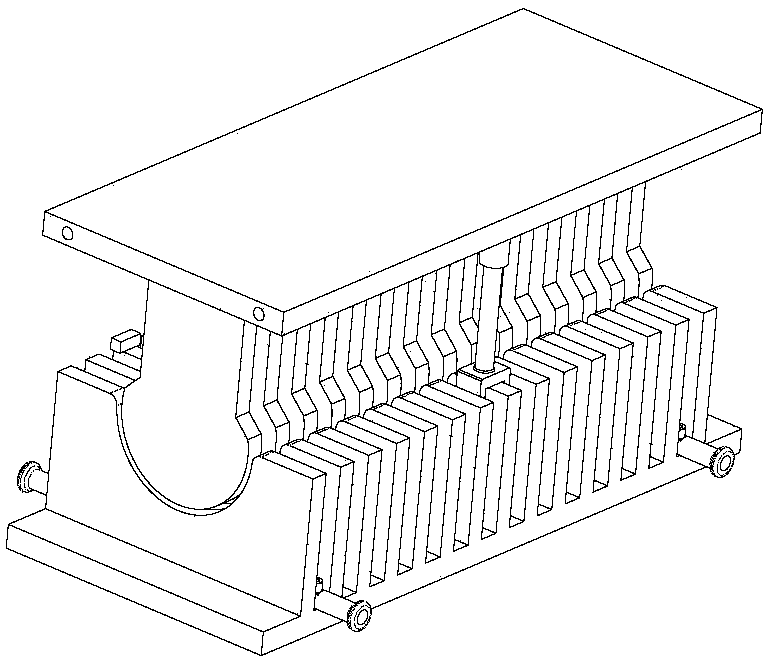

[0027] The patent of the present invention also relates to a mold mechanism used in conjunction with a press. The mold mechanism includes a mold A and a mold B; ...

Embodiment 2

[0030] The profiling process steps of the tubular part are the same as in Embodiment 1, the difference is that:

[0031] The upper mold of the mold A and the mold B is provided with a mold handle;

[0032] The mold A is provided with a pillar 2 for the upper template to move up and down, and the pillar 2 is provided with a spring for easy mold opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com