A processing system for tripod-type universal joints

A processing system and universal joint technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of inaccurate centering and reversing angles, low product precision, and high labor intensity, etc., to reduce error, improve product accuracy, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

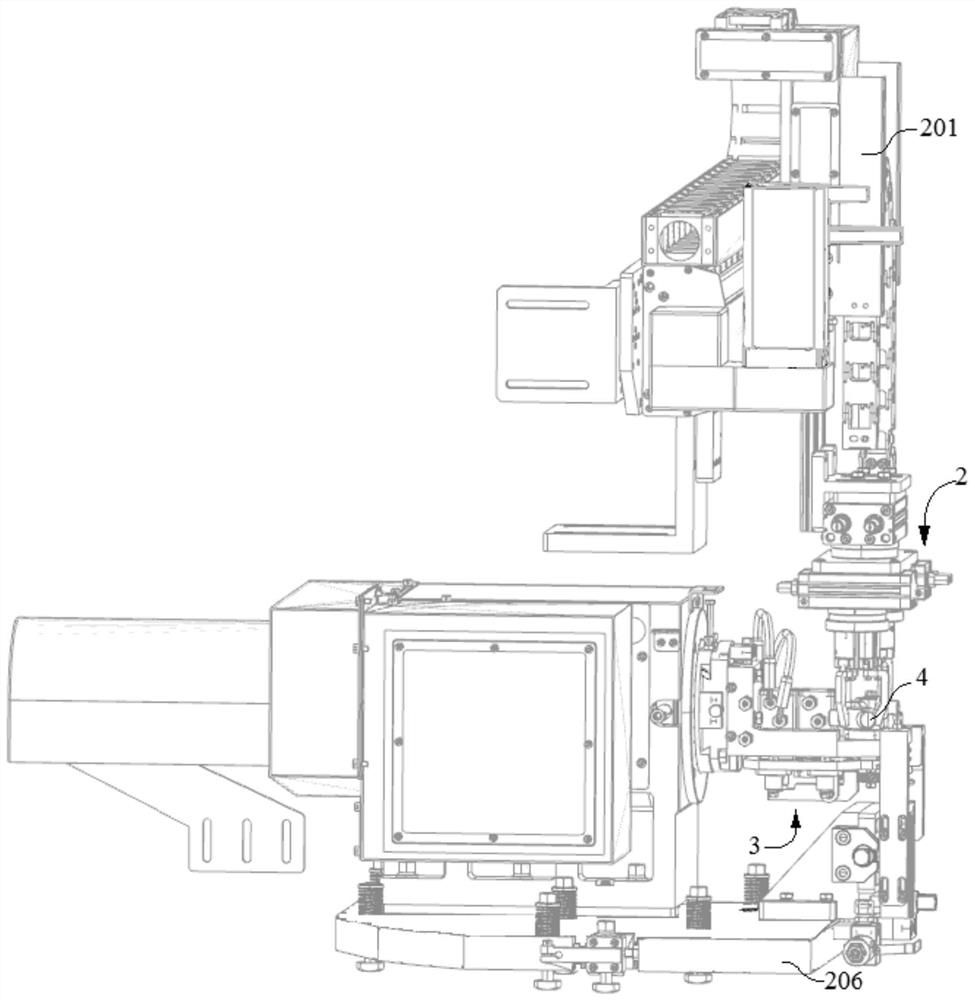

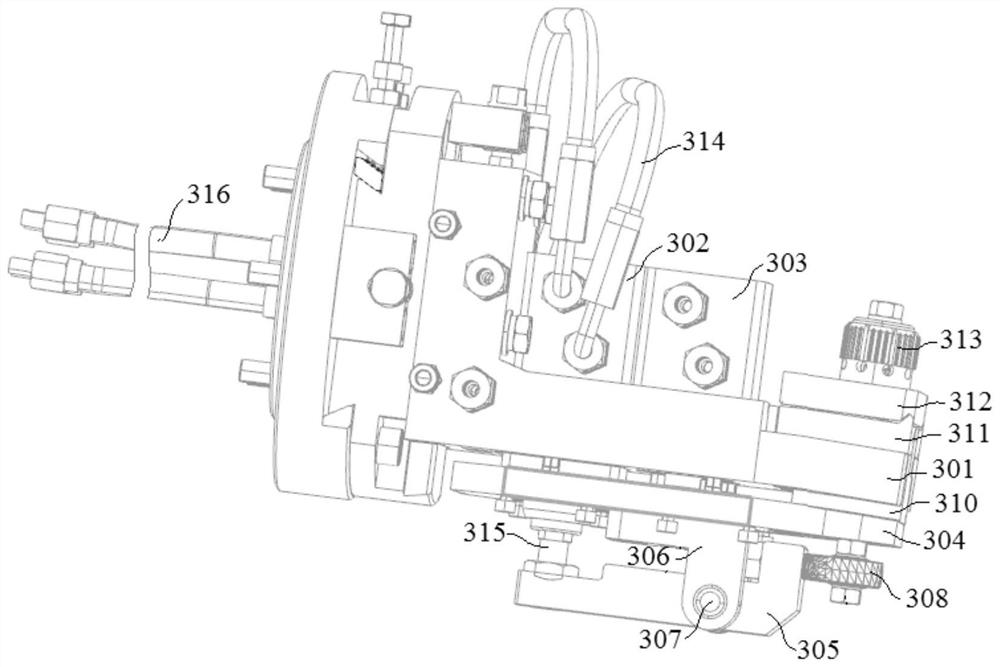

[0049] Such as figure 1 , figure 2 and Figure 10 As shown, a processing system for a three-pin shaft universal joint in this embodiment includes three components: a loading and unloading unit 1, a grasping and positioning unit 2, and a clamp unit 3. The loading and unloading unit 1 is used for three The pin-type universal joint 4 is transported, and the grabbing and positioning unit 2 grabs the tripod-type universal joint 4 and sends it to the clamp unit 3 for processing. Such as Figure 4 As shown, the clamp unit 3 includes a clamp mounting plate 301, a positioning convex ring 311, a positioning concave ring 312, a mandrel 309, a first driving mechanism and a second driving mechanism, and the positioning convex ring 311 is fixedly installed on the clamp mounting plate 301, the positioning concave ring 312 is located above the positioning convex ring 311 and is engaged with it. One end of the mandrel 309 is provided with an elastic expansion sleeve 313, and the other end ...

Embodiment 2

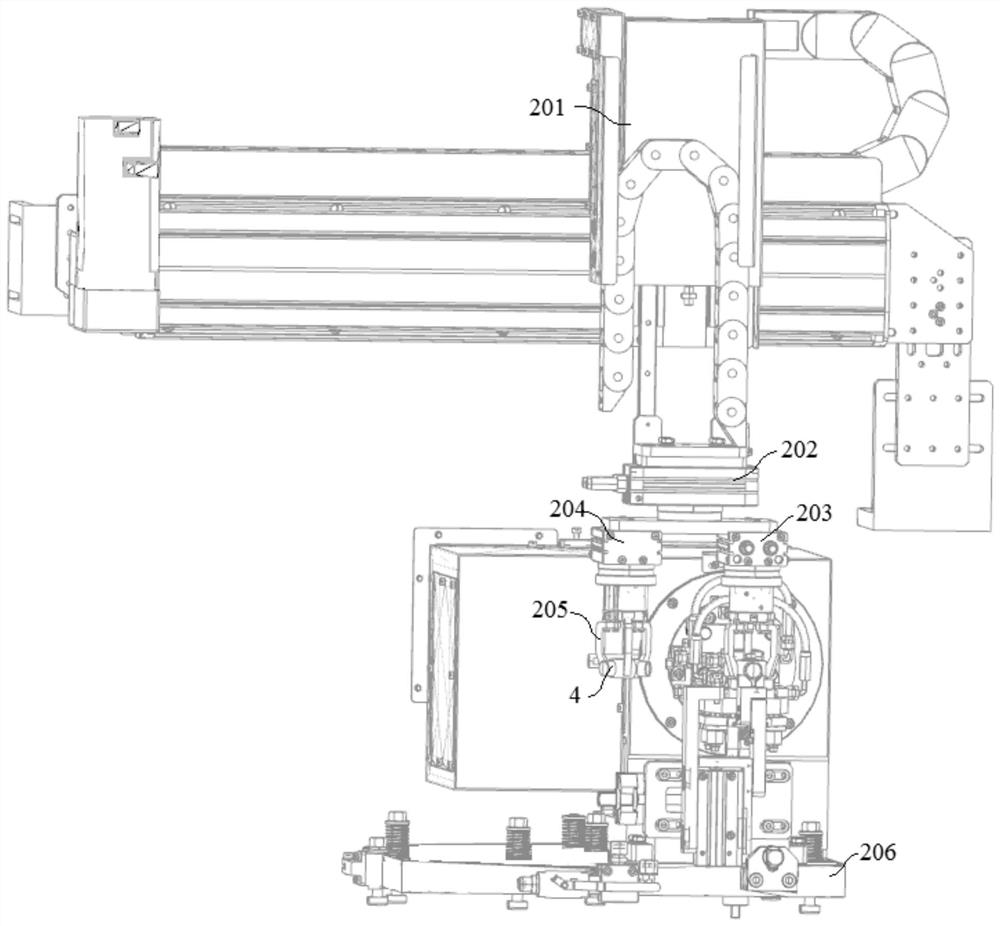

[0054] The structure of the processing system of a three-pin shaft universal joint in this embodiment is basically the same as in Embodiment 1, the main difference is that the grasping and positioning unit 2 includes two air grippers 205 and a positioning block 211, such as Figure 7 As shown, the two air claws 205 are installed on the rotary plate 213 through the second rotary cylinder 203 and the third rotary cylinder 204 respectively, and the second rotary cylinder 203 and the third rotary cylinder 204 respectively control the movement of the air claws 205 connected thereto. Rotation; the rotating plate 213 is installed below the cantilever crane 201 through the first rotating cylinder 202, and the rotating plate 213 is driven to rotate by the first rotating cylinder 202, thereby controlling the rotation of the second rotating cylinder 203 and the third rotating cylinder 204; by using The second and third rotary cylinders control their corresponding air claws 205 to grab the...

Embodiment 3

[0059] The processing system of a three-pin shaft type universal joint in this embodiment is basically the same in structure as in Embodiment 2. When using this processing system for processing, it specifically includes the following steps:

[0060] Step 1. Put multiple three-pin universal joints 4 into the discharge pipe 105 of the loading and unloading unit 1, and drive the L-shaped push plate through the telescopic cylinder 108 to push the three-pin universal joints 4 to the discharge conveyor belt 103, transport it to the discharge conveyor belt 103 front end contact stop block 115 and wait for the grasping and positioning unit 2 to grasp and process after it stops; Grabbing and processing, the follow-up tripod-type universal joint 4 will be stopped by the stop cylinder 109 until the front tripod-type universal joint 4 is grabbed and processed, and the subsequent adjacent tripod-type universal joints The knuckle 4 will not move until the stop block 115 stops and waits to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com