Industrial wire drawing equipment for surface of metal disc

A metal disc and surface drawing technology, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low quality of disc drawing, long time consumption, low work efficiency, etc., and achieve convenience Effects of collection, reduction of cost loss, and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

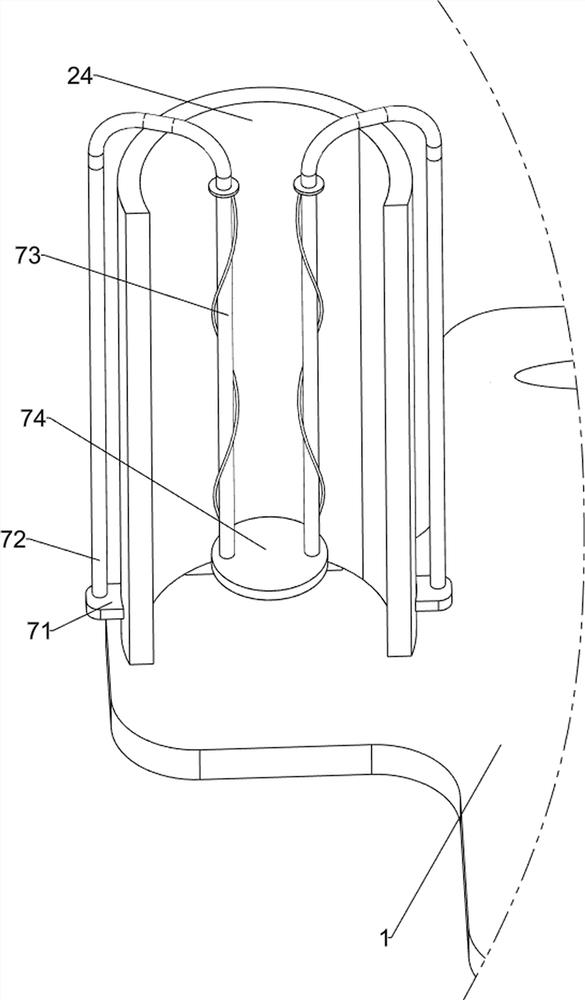

[0066] An industrial wire drawing equipment for the surface of metal discs, such as figure 1 As shown, it includes a base 1, a pushing mechanism 2, an abrasive belt drawing mechanism 3 and a sand pressing mechanism 4. The left side of the base 1 is provided with a pushing mechanism 2, and the base 1 is provided with an abrasive belt drawing mechanism 3. A sand pressing mechanism 4 is provided between the base 1 and the pushing mechanism 2 .

[0067] When people need to process the surface of the metal disc, people place the metal disc in the pusher mechanism 2. At this time, people open the pusher mechanism 2 and the abrasive belt drawing mechanism 3, so that the pusher mechanism 2 pushes the metal disc Push it to the right, and then push the metal disc to the bottom of the abrasive belt wire drawing mechanism 3. Since the pushing mechanism 2 moves to the right, the sand pressing mechanism 4 moves to the right, and then the sand pressing mechanism 4 pushes the abrasive belt wi...

Embodiment 2

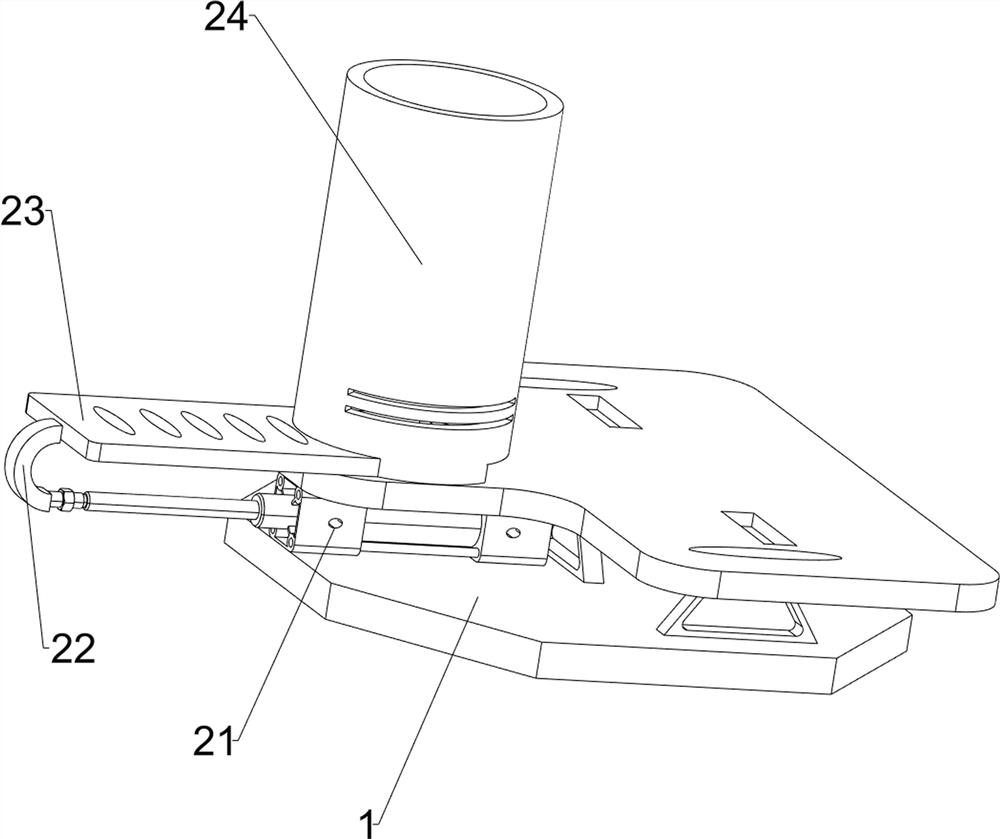

[0069] On the basis of Example 1, such as figure 2 As shown, the pushing mechanism 2 includes a cylinder 21, an arc-shaped connecting rod 22, a push plate 23 and a feeding box 24, the left side of the base 1 is provided with a cylinder 21, and the output shaft of the cylinder 21 is connected with an arc-shaped connecting rod 22 , The right end of the arc-shaped connecting rod 22 is provided with a push plate 23, the push plate 23 is slidably connected with the base 1, and the upper left side of the base 1 is provided with a blanking box 24.

[0070] When people need to process metal discs, they place the metal discs in the blanking box 24. At this time, the metal discs are located on the base 1, and people open the cylinder 21 so that the output shaft of the cylinder 21 drives the arc connection. The rod 22 moves to the right, and then drives the push plate 23 to move to the right, so that the push plate 23 pushes the metal disc to move to the right, pushes the metal disc to ...

Embodiment 3

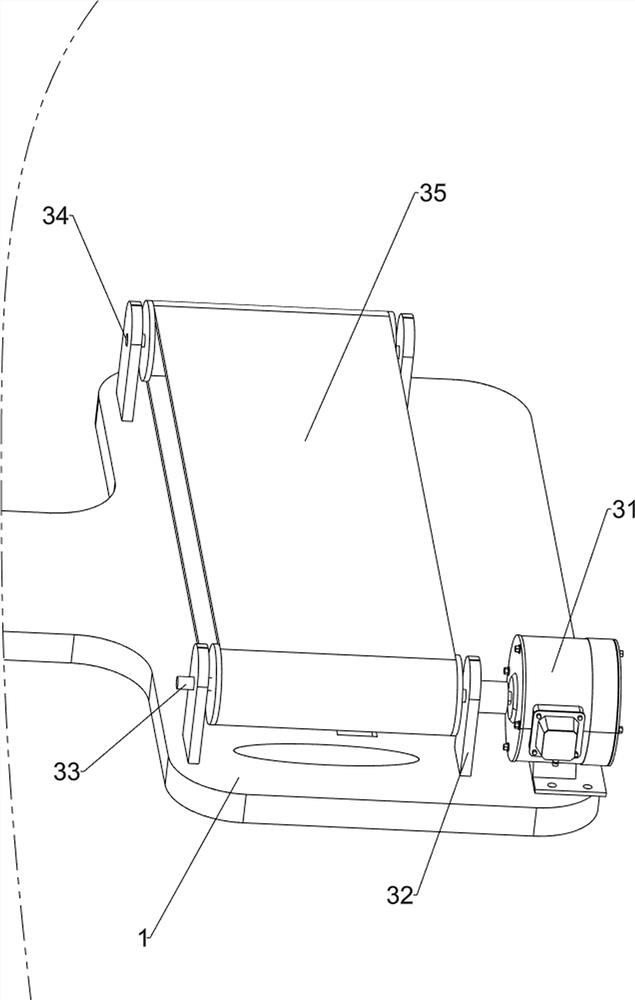

[0072] On the basis of Example 2, such as figure 1 , Figure 3-Figure 7 As shown, the abrasive belt wire drawing mechanism 3 includes a motor 31, a first bearing seat 32, a first rotating shaft 33, a second rotating shaft 34 and a rotating abrasive belt 35, and the right front portion on the base 1 is provided with a motor 31, and the base 1 The first bearing seat 32 is symmetrically arranged on the front, rear, left and right sides, and the first rotating shaft 33 is arranged in a rotating manner between the two first bearing seats 32 on the front side. The first rotating shaft 33 is connected with the output shaft of the motor 31. A second rotating shaft 34 is rotatably arranged between the first bearing seats 32, and a rotating abrasive belt 35 is wound between the first rotating shaft 33 and the second rotating shaft 34.

[0073] When the push plate 23 pushes the metal disk under the rotating abrasive belt 35, people turn on the motor 31, so that the output shaft of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com