Vacuum auxiliary heating cabin for coating machine

A vacuum-assisted coating machine technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of increasing vacuuming time, occupying a large area, and increasing manufacturing costs due to large volume. Reduce cabin space and evenly heat the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further description below in conjunction with accompanying drawings.

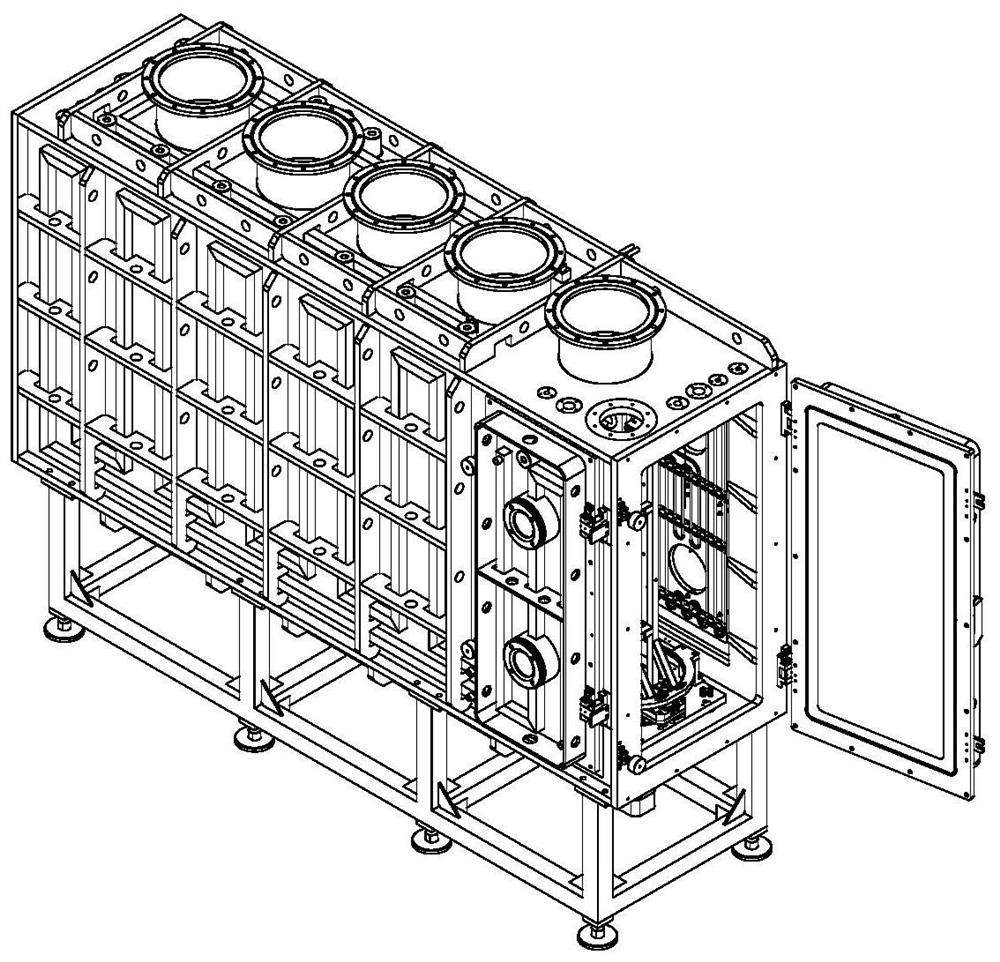

[0027] figure 1 It is an external schematic diagram of a square heating cabin according to an embodiment of the present invention, which shows the structure of a square cabin from a three-dimensional perspective.

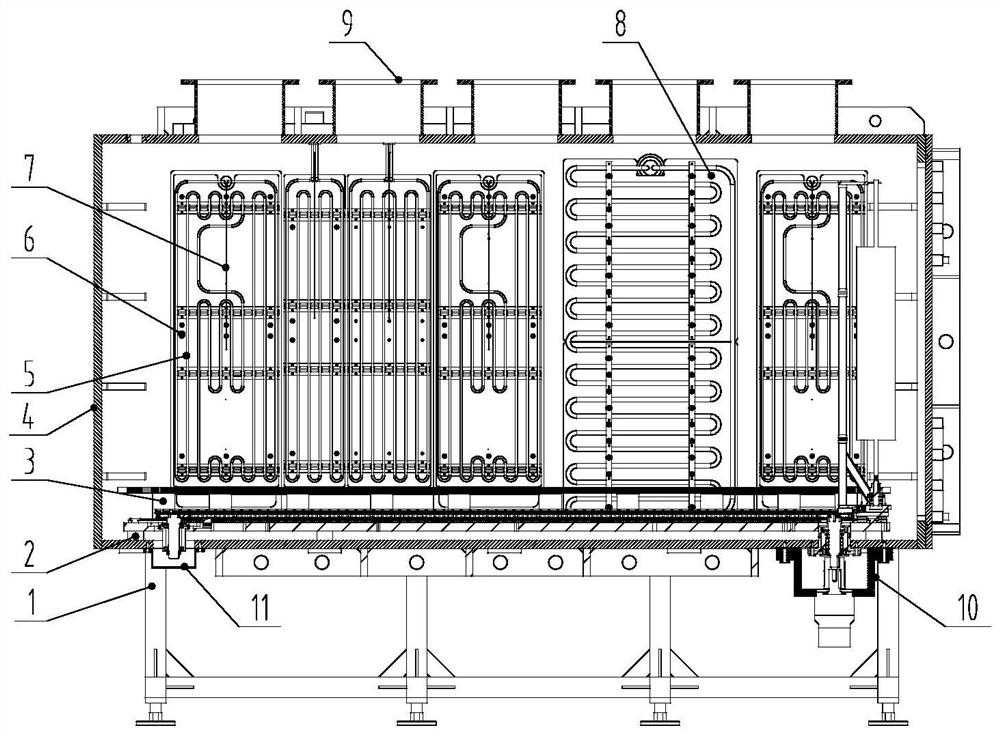

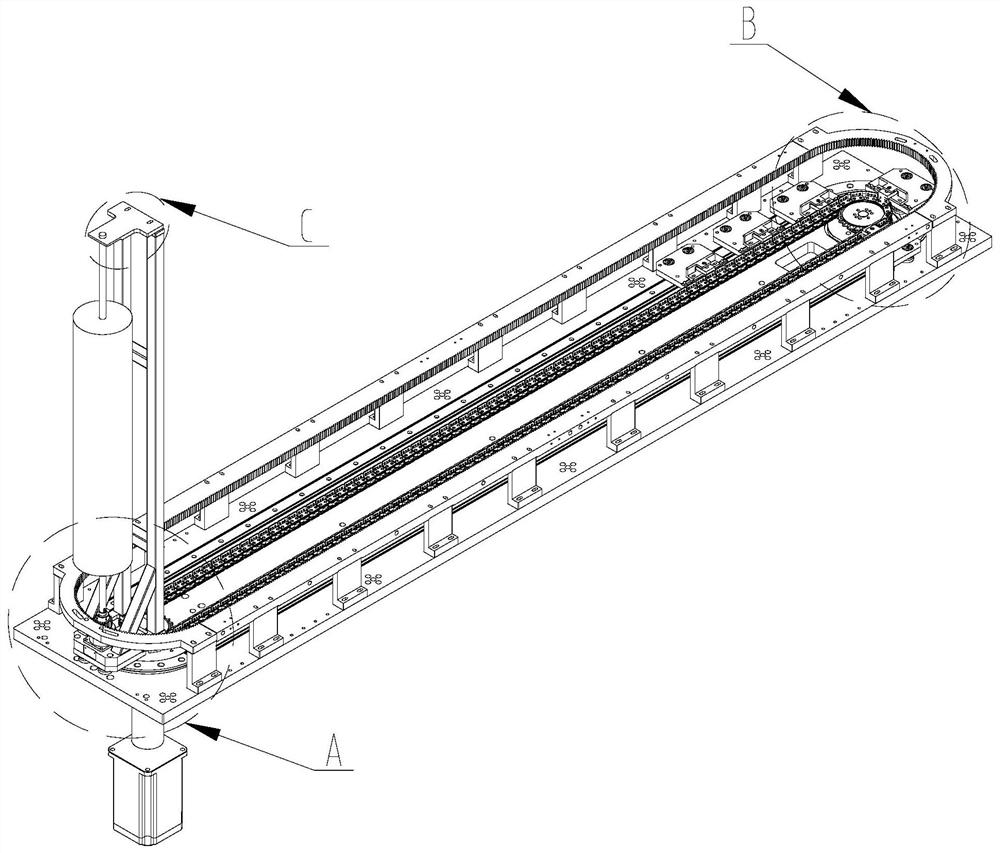

[0028] figure 2 It is a schematic diagram of the interior of the square heating cabin. It shows that the square heating cabin is made up of frame 1, long circular track 3 and heating cabin 4. Similar to the side track of a football field, the long circular track 3 composed of two parallel symmetrical straight lines and two semicircular arcs is fixed on the long circular track fixing seat 2 by screws, and the long circular track fixing seat 2 is fixed on the heating cabin 4 by screws On the bottom plate, the heater 5 is fixed on the side wall of the cabin body through the heater fixing part 6, the temperature measuring probe 7 is fixed next to the heating pipe of the heater 5, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com