Raw material purifying and screening device for electronic-grade copper sulfate powder

A technology of copper sulfate powder and screening device, which is applied in the direction of filtering, solid separation, and drying gas arrangement, etc., which can solve the problems affecting the normal use of the screening seat, difficult copper sulfate raw materials, poor screening effect, etc., and achieve screening Good effect, reduce moisture phenomenon, improve screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

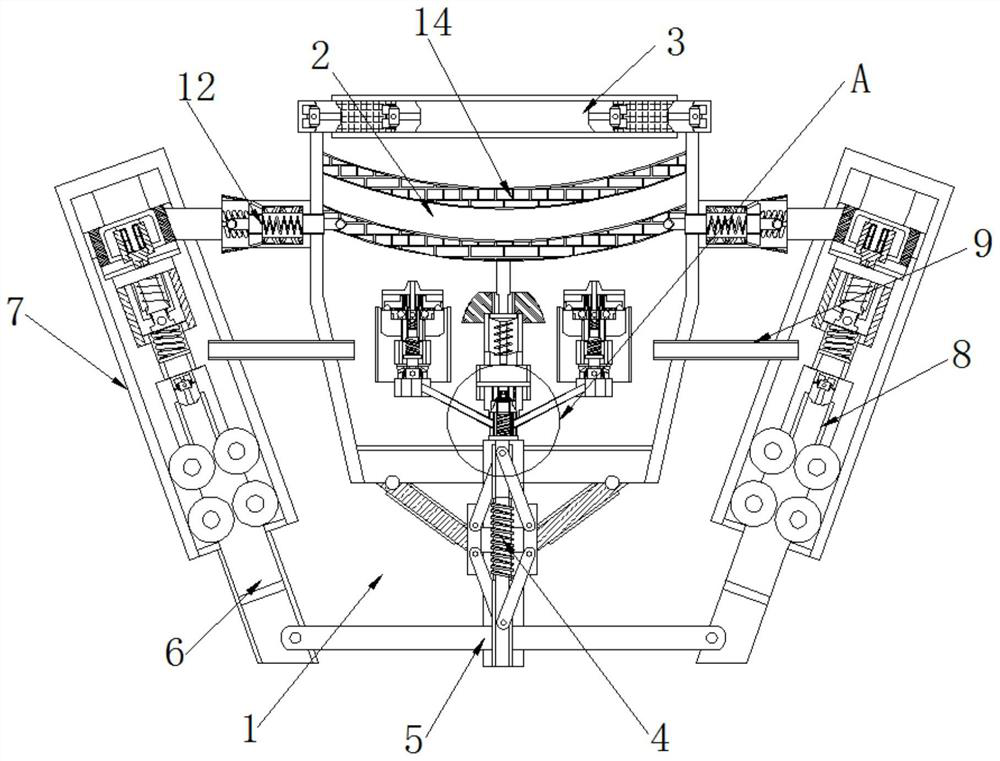

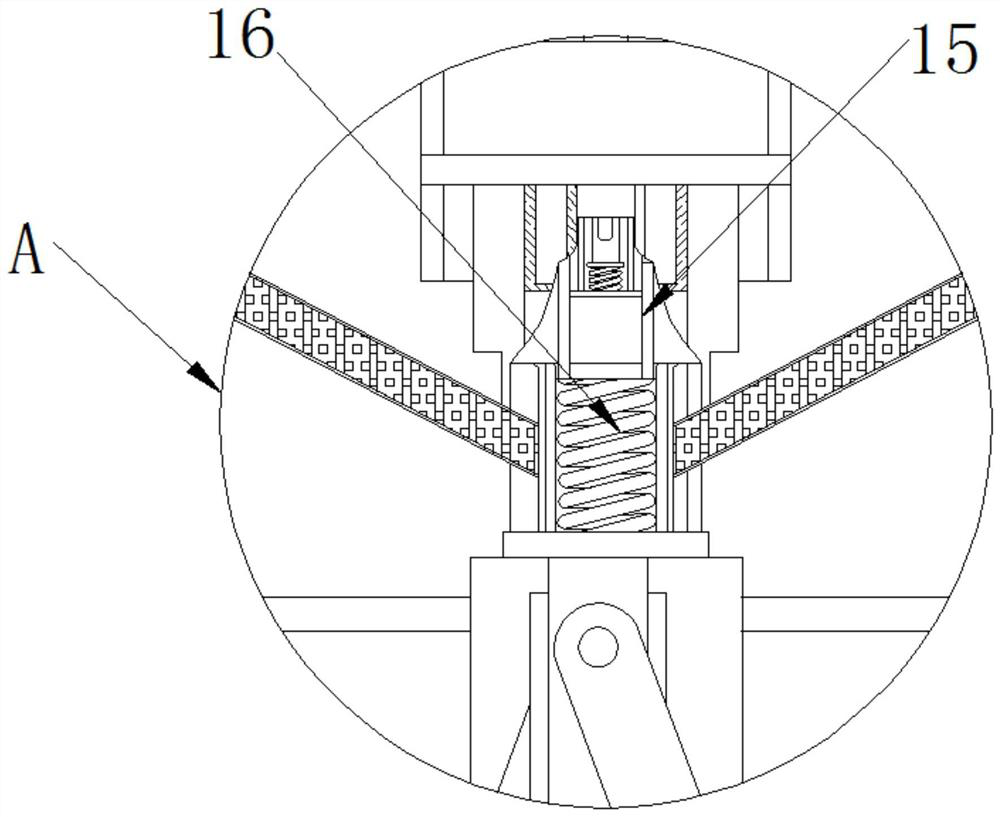

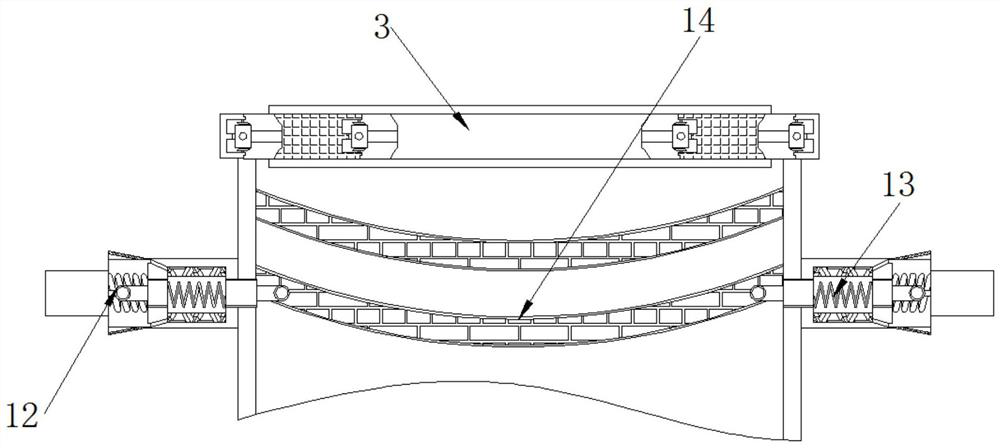

[0025] as attached figure 1 to attach Figure 8 Shown:

[0026] The invention provides a raw material purification and screening device for electronic grade copper sulfate powder, comprising a support base 1, the upper surface of the support base 1 is fixedly connected with a screening base 2, and the outer surface of the screening base 2 is provided with a feeding port 3, The inside of the support base 1 is connected with threaded column 4 for rotation, and the left and right sides of threaded column 4 are movably connected with engaging rod 5, and the surface of engaging rod 5 is provided with teeth suitable for threaded column 4, and one end of engaging rod 5 A compression column 6 is movably connected, and one end of the compression column 6 runs through the interior of the hollow cavity seat 7, and the surface of the hollow cavity seat 7 is provided with a sliding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com