Tire processing equipment

A processing equipment and tire technology, applied in the field of tire processing, can solve the problems of artificial bead placement, etc., and achieve the effect of protecting safety, high quality and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

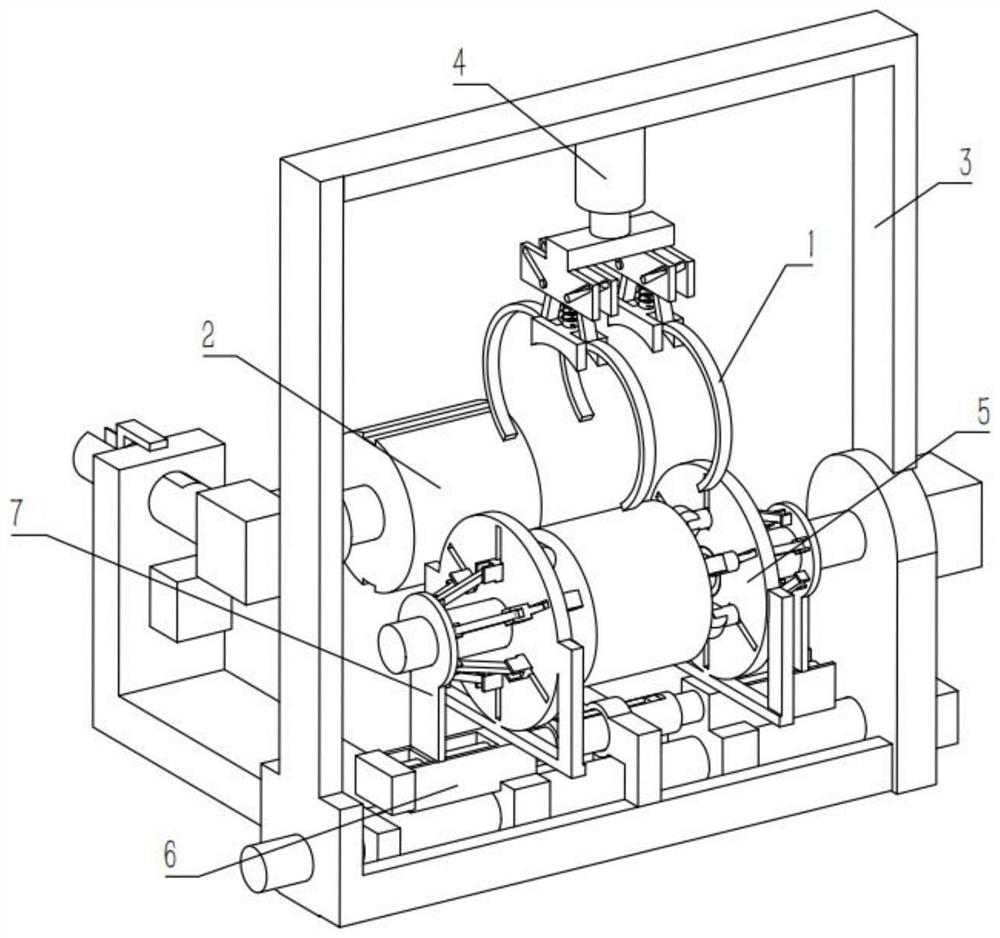

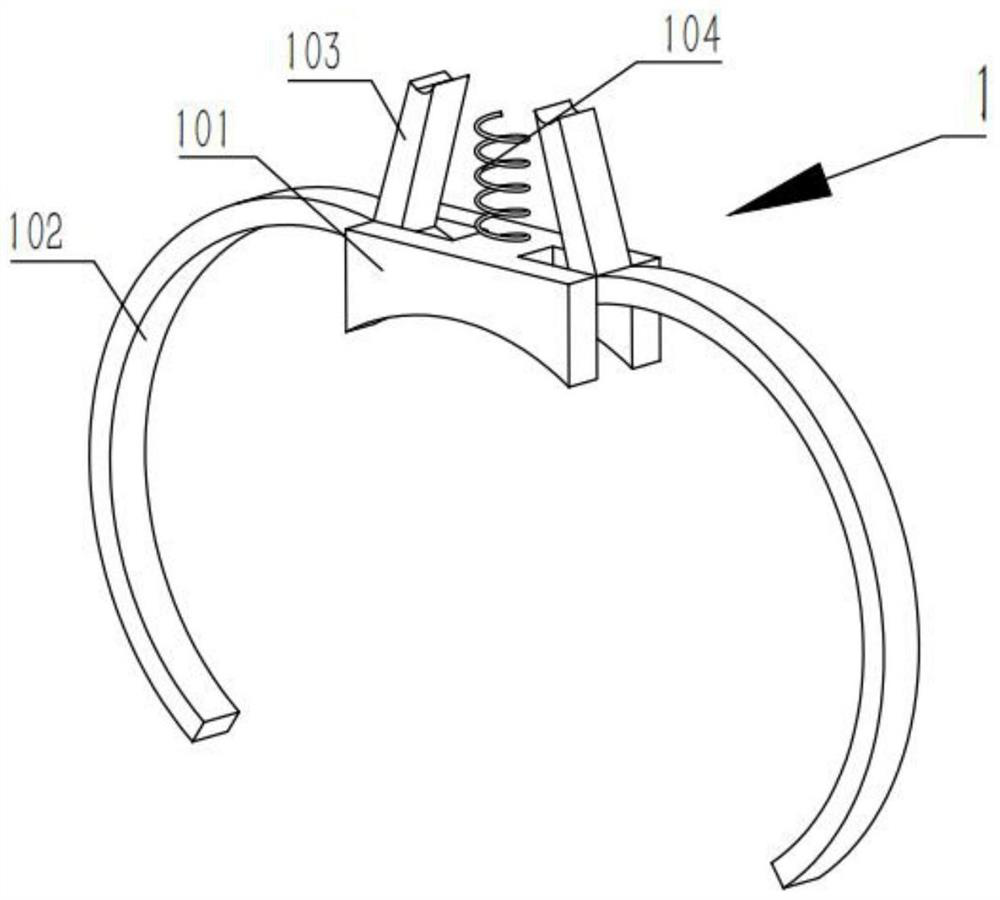

[0029] Combine below Figure 1-8 Illustrating this embodiment, a tire processing equipment includes a position limiting mechanism 1, a bead fixing mechanism 2 and a main frame mechanism 3, characterized in that the position limiting mechanism 1 includes an annular frame fixing plate 101, an annular fixing frame 102, The rotating rod 103 and the spring 104, the two annular fixing frames 102 are both rotatably connected to the annular frame fixing plate 101, the two rotating rods 103 are respectively fixedly connected to the upper ends of the two annular fixing frames 102, and the lower end of the spring 104 is fixedly connected to the annular frame. On the upper end of the frame fixing plate 101, the bead fixing mechanism 2 includes a telescopic rod 207 and a bead placer 208, and the bead placer 208 is fixedly connected to the telescopic rod 207, and the main frame mechanism 3 includes a tire building roller 304;

[0030]The placement of the bead can be completed automatically,...

specific Embodiment approach 2

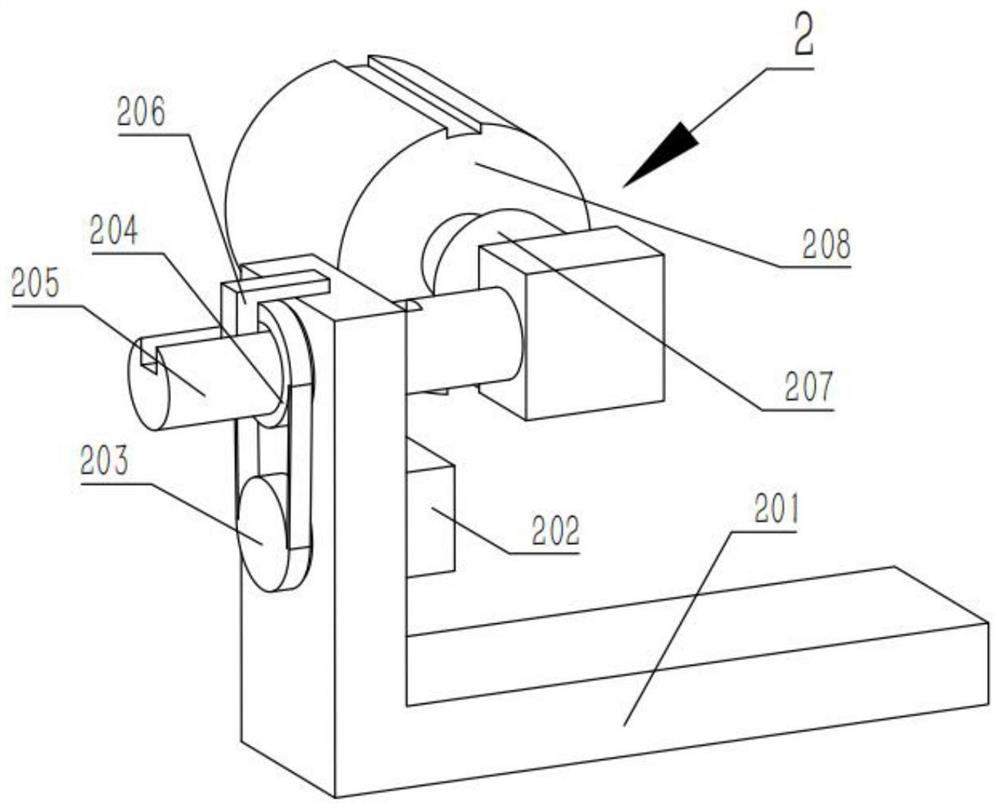

[0032] Combine below Figure 1-8 Describing this embodiment, this embodiment further describes Embodiment 1. The bead fixing mechanism 2 further includes a bead fixing frame 201, a motor 202, a pulley 203, a threaded ring 204, a threaded rod 205 and a rotation limiting rod 206. The motor 202 is fixedly connected to the bead holder 201, the pulley 203 is fixedly connected to the output shaft of the motor 202, the pulley 203 is rotatably connected to the bead holder 201, the threaded ring 204 is rotatably connected to the bead holder 201, and the threaded rod 205 and the threaded ring 204 are driven by threads, the pulley 203 and the threaded ring 204 are driven by a belt, the rotation limiting rod 206 is fixedly connected to the bead holder 201, the threaded rod 205 is provided with a chute, and the threaded rod 205 is slidably connected to the threaded rod 205. On the ring 204, the telescopic rod 207 is fixedly connected to the threaded rod 205;

[0033] The rotation of the o...

specific Embodiment approach 3

[0035] Combine below Figure 1-8 Describing this embodiment, this embodiment further describes Embodiment 2. The main body frame mechanism 3 further includes a main body support frame 301, a sliding rail 302, a rotating shaft 303 and a power motor 305. The sliding rail 302 is fixedly connected to the main body support frame At the bottom end of 301, the rotating shaft 303 is rotatably connected to the right end of the main body support frame 301, the power motor 305 is fixedly connected to the right end of the main body support frame 301, the rotating shaft 303 is fixedly connected to the output shaft of the power motor 305, and the tire building roller 304 is fixed connected to the left end of the rotating shaft 303;

[0036] The rotation of the output shaft of the power motor 305 drives the rotation of the rotation shaft 303, and the rotation of the rotation shaft 303 drives the rotation of the tire building roller 304, and the rotation of the tire building roller 304 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com