Stepless speed regulation micro carving pen with buffering function

A stepless speed regulation and micro-carving technology, applied in the electromechanical field, can solve the problems of uncontrollable engraving pen speed, no buffer function of the cutter head, damage to the material to be processed, etc., and achieve the effect of light weight, small length and improved portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

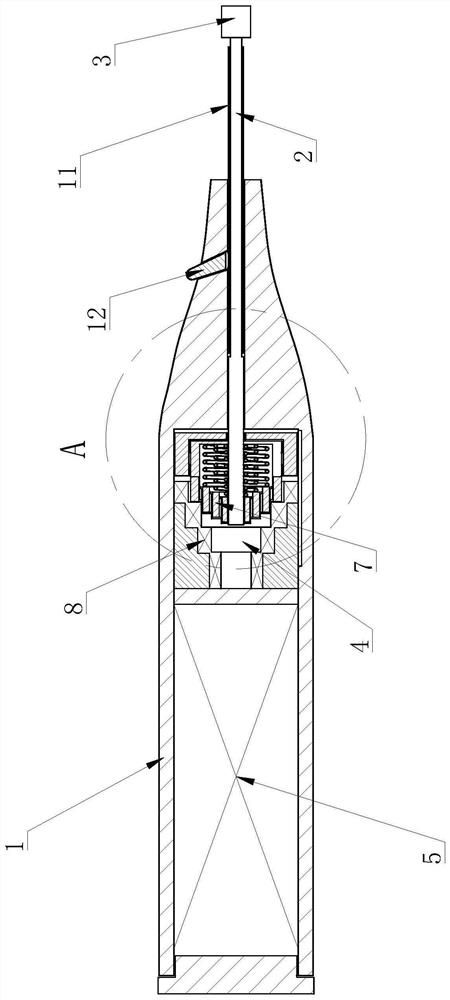

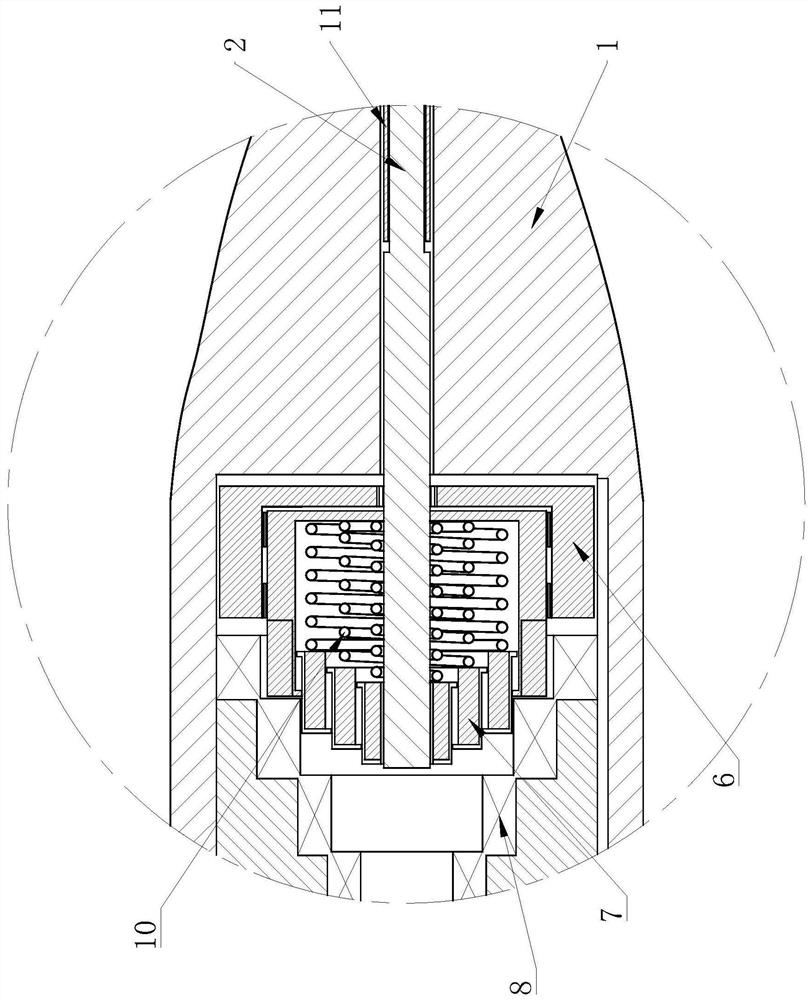

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0016] like figure 1 and figure 2 As shown, it includes a pen tube 1, a rotating shaft 2 and a cutter head tooling 3. The inner cavity of the pen tube 1 is divided into an installation cavity 4 and a storage cavity by a partition. A push block 6 is slidably connected to one end close to the nib, the rotating shaft 2 is rotatably connected to the pushing block 6, the inner end of the rotating shaft 2 is fixedly provided with a rotor 7, the outer end of the rotating shaft 2 is fixedly connected with the cutter head tooling 3, and the installation cavity 4 is far away from the end of the nib A fixed stator 8 is fixed, and the winding is electrically connected to the mobile power supply 5;

[0017] The stator 8 includes sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com