Basalt fiber asphalt preparation and performance evaluation method for simulating actual mixing process

A technology of basalt fiber and basalt, which is applied in the field of basalt fiber asphalt preparation and performance evaluation to simulate the actual mixing process, and can solve problems such as difficult mechanism of action and small proportion of basalt fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of basalt fiber pitch simulating actual mixing process, comprising the following steps:

[0028] (1) Weigh 1007.6 g of basalt coarse aggregate with a particle size between 16 and 26.5 mm, wash it with clean water, and dry it in an oven at 102 to 108 °C.

[0029] (2) Heat the dried basalt aggregate in an oven at 162-178°C for 4-5 hours, and raise the temperature of the mixing pot to 170-180°C.

[0030] (3) Weigh 3.1g of 6mm basalt fiber, put it into the mixing pot together with the aggregate and stir for 85-95s, and use tweezers to separate the basalt fiber from the aggregate after the stirring is completed.

[0031] (4) Weigh 117.9 g of base asphalt, and heat it to 162-178° C. on an induction cooker to make the asphalt in a completely fluid state.

[0032] (5) Weigh 0.6g of the dispersed basalt fiber, and add the basalt fiber to the matrix asphalt in batches with tweezers. After the basalt fiber is completely immersed in the matrix asphalt, use an ...

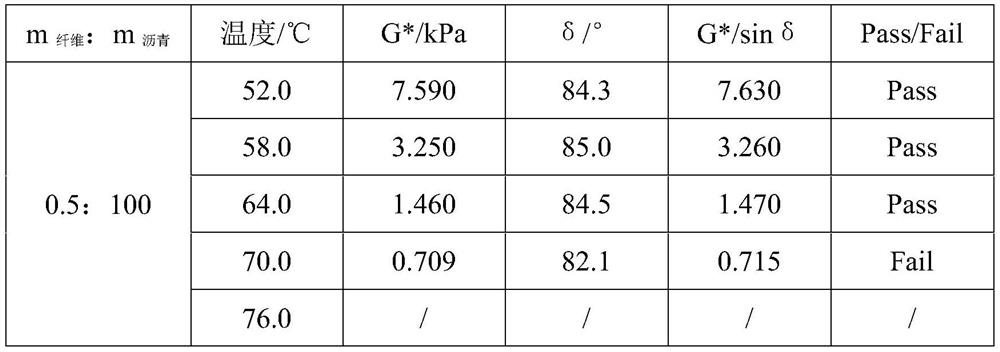

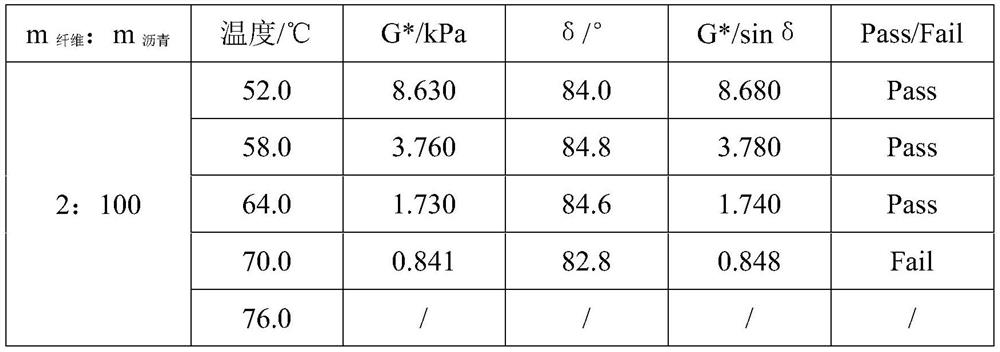

Embodiment 2

[0040] A preparation method of basalt fiber pitch simulating actual mixing process, comprising the following steps:

[0041] (1) Weigh 1003.9 g of basalt coarse aggregate with a particle size between 16 and 26.5 mm, wash it with clean water, and dry it in an oven at 102 to 108 °C.

[0042] (2) Heat the dried basalt aggregate in an oven at 162-178°C for 4-5 hours, and raise the temperature of the mixing pot to 170-180°C.

[0043] (3) Weigh 3.3g of 6mm basalt fiber, put it into the mixing pot together with the aggregate and stir for 85-95s, and use tweezers to separate the basalt fiber from the aggregate after the stirring is completed.

[0044] (4) Weigh 126.6g of base asphalt, and heat it to 162-178°C on an induction cooker to make the asphalt in a completely fluid state.

[0045] (5) Weigh 2.5 g of the dispersed basalt fiber, and add the basalt fiber into the matrix asphalt in batches with tweezers. After the basalt fiber is completely immersed in the matrix asphalt, use an ...

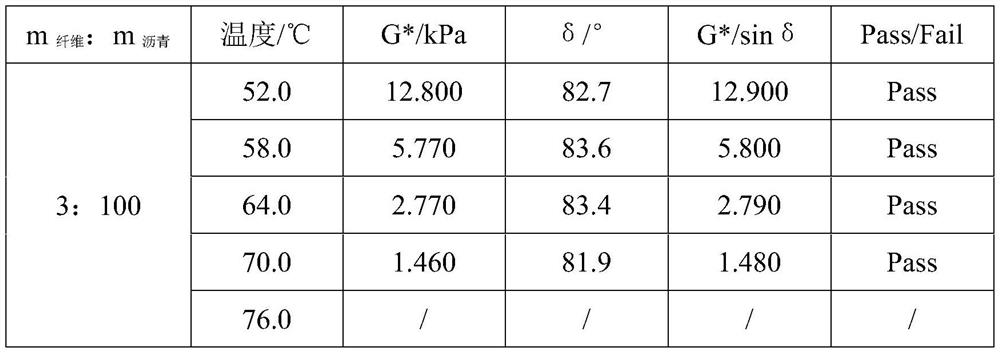

Embodiment 3

[0053] A preparation method of basalt fiber pitch simulating actual mixing process, comprising the following steps:

[0054] (1) Weigh 2001.6 g of basalt coarse aggregate with a particle size between 16 and 26.5 mm, wash it with clean water, and dry it in an oven at 102 to 108 °C.

[0055] (2) Heat the dried basalt aggregate in an oven at 162-178°C for 4-5 hours, and raise the temperature of the mixing pot to 170-180°C.

[0056] (3) Weigh 6.1g of 6mm basalt fiber, put it into the mixing pot together with the aggregate and stir for 85-95s, and use tweezers to separate the basalt fiber from the aggregate after the stirring is completed.

[0057] (4) Weigh 102.9 g of base asphalt, and heat it to 162-178° C. on an induction cooker to make the asphalt in a completely fluid state.

[0058] (5) Weigh 3.1 g of the dispersed basalt fiber, and add the basalt fiber to the matrix asphalt in batches with tweezers. After the basalt fiber is completely immersed in the matrix asphalt, stir w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com