Styrenic block copolymer and preparation method thereof

A technology of block copolymers and styrenes, which is applied in the field of styrenic block copolymers and its preparation, can solve the problems of cumbersome steps for hydroxyl-functionalized polymers, difficulty in controlling the sulfonation reaction process, and cumbersome preparation process, etc. Achieve the effects of improving the use temperature and thermal stability, enhancing interaction, and enhancing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the styrenic block copolymer provided by the invention comprises the following steps:

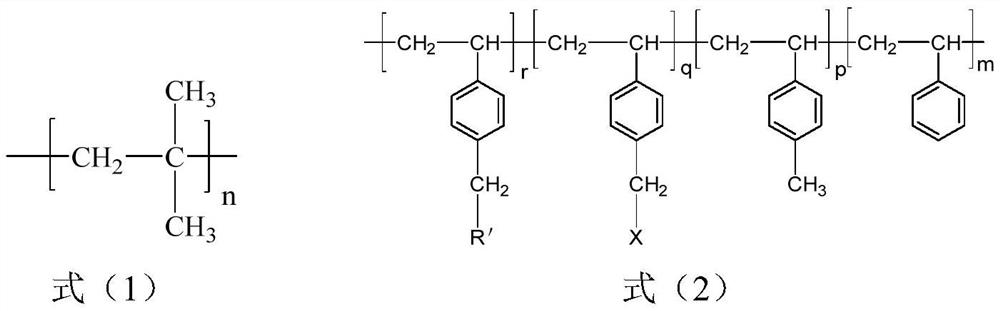

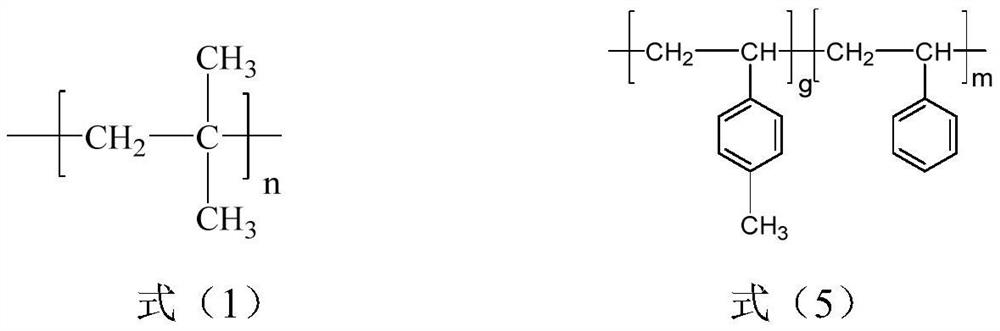

[0028] S1, isobutylene, styrene and p-methylstyrene are obtained through sequential living cationic copolymerization in the presence of an initiating system to obtain a polyisobutylene segment with a structure shown in formula (1) and styrene with a structure shown in formula (5) Block copolymers (SMB) of random copolymerized segments with p-methylstyrene structural units;

[0029]

[0030] Wherein, n is 200~1800, the total number (m) of styrene structural units accounts for 0.5~29% of the total moles of all structural units, and the total number (g) of p-methylstyrene structural units accounts for 0.5~29% of the total moles of all structural units. 1.05-43%.

[0031] S2, carry out bromination reaction / chlorination reaction in organic solvent with the block copolymer obtained in step S1 and bromination / chlorination reagent, obtain bromination / chlorinatio...

Embodiment 1

[0078] This example serves to illustrate the azonia-ionized poly[(p-methylstyrene-co-styrene)-b-isobutylene-b-(styrene-co-p-methylstyrene)] block copolymer (FSMB -1) Preparation and properties.

[0079] Preparation of S1 and SMB-1

[0080] Under the protection of high-purity nitrogen at -78°C, 110 mL of dichloromethane, 164 mL of n-hexane, 0.3 mol of isobutene (IB) and 0.845 mmol of bifunctional initiator 1,4-bis(2-chloro-2 -Propyl)benzene (DCC), add 7.0mL containing co-initiator FeCl 3 With the additive isopropanol (POH) solution (of which: FeCl 3 :POH=1:1.4), so that the concentration of IB in the reaction system is 1.0mol / L, DCC:FeCl 3 : IB=1:3.6:355 (molar ratio), reaction 15min, IB monomer is fully converted, obtains polyisobutylene double-end active chain; Add 100mL containing styrene (St, 68.7mmol) and p-methylstyrene (pMS, 34.4mmol) in dichloromethane / normal hexane (4 / 6, v / v) mixed solution, further carry out active cationic block copolymerization reaction, the rea...

Embodiment 2

[0088] The preparation method of S1 and SMB-2 is the same as step S1 in Example 1. At -80°C and under the protection of high-purity nitrogen, add 220mL of dichloromethane, 328mL of n-hexane, 0.6mol of isobutene and 3.38mmol of DCC into the polymerization reactor and mix well, add 14mL of FeCl containing co-initiator 3 With POH solution (where: FeCl 3 :POH=1:1.4), so that the concentration of IB in the reaction system is 1.0mol / L, DCC:FeCl 3 : IB=1:3.6:178 (molar ratio), polymerization reaction 15min, IB monomer is fully transformed, obtains polyisobutylene two-terminal active chain; Only the feeding amount of St and pMS mixed solution is reduced, add 120mL containing 82.4mmol styrene and 41.2mmol methylene chloride / n-hexane (4 / 6, v / v) mixed solution of p-methylstyrene, obtain poly(styrene-co-p-methylstyrene)-b-polyisobutylene-b-poly( Styrene-co-p-methylstyrene) triblock copolymer SMB-2.

[0089] S2, BSMB-2 preparation method is the same as step S2 in embodiment 1, just Br2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com