Steel making system and method

A steel and sliding connection technology, applied in the field of steelmaking systems, can solve problems such as the inability to grasp the quality of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

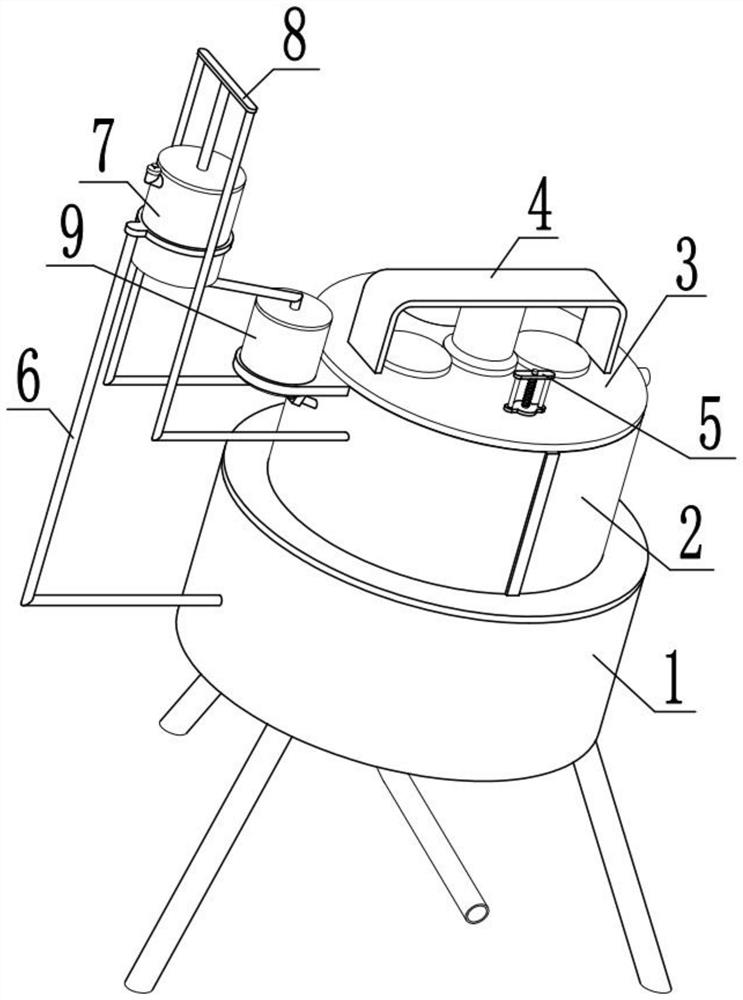

[0037] Combine below Figure 1-10 Describe this embodiment, the present invention relates to the technical field of steelmaking, more specifically a steelmaking system and method, including a steel heating device 1, a steel smelting device 2, a shielding stirring device 3, a stirring power device 4, a pressure relief balance The device 5, the extension bearing device 6, the additive storage member 7, the linkage displacement device 8 and the interval storage device 9 place the steel in the smelting chamber 2-1, and when the steel enters the smelting chamber 2-1, the smelting chamber 2-1 1 will become heavier, driving the pressurized circular plate 8-4 to move downward, the additive located in the storage barrel 7-1 will flow into the hovering barrel 9-2 through the connecting slide tube 7-5, and start the storage chamber 1- The electric arc furnace in 1 heats the steel. When the steel gradually softens, the motor 4-2 is started, and the gear II4-3 meshes with the two gears I3-...

specific Embodiment approach 2

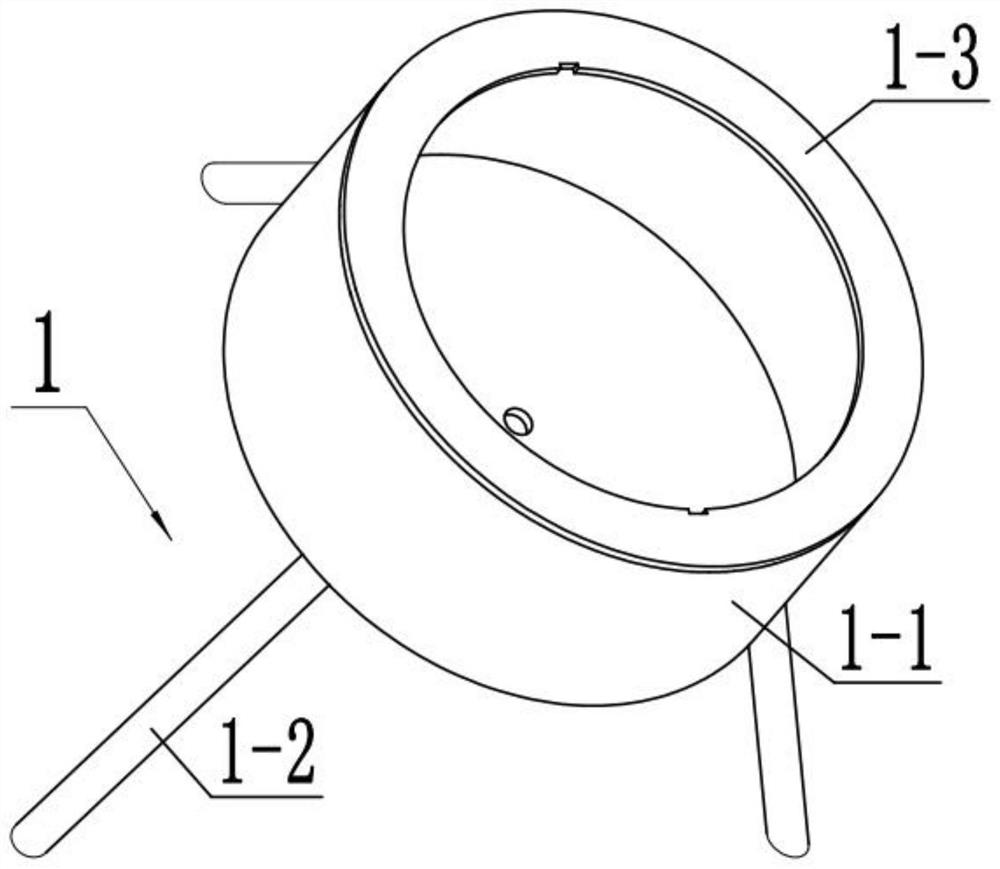

[0040] Combine below Figure 1-10 Describe this embodiment. This embodiment will further explain Embodiment 1. The iron and steel heating device 1 includes a storage chamber 1-1, an inclined leg 1-2 and a limiting ring 1-3. The storage chamber 1-1 serves as The function of load-carrying connection, the inside of the storage chamber 1-1 is fixedly connected with an electric arc furnace, the electric arc furnace can generate an electrode arc, and when the electrode arc occurs, it will generate high temperature, which can melt steel, and the lower part of the storage chamber 1-1 is evenly fixed and connected Three inclined legs 1-2 are used to support and fix the whole device, and the upper part of the storage chamber 1-1 is fixedly connected with the limit ring 1-3, and the limit ring 1-3 is set There is a keyway, which is convenient to limit the melting chamber 2-1, so that the melting chamber 2-1 can only slide up and down.

specific Embodiment approach 3

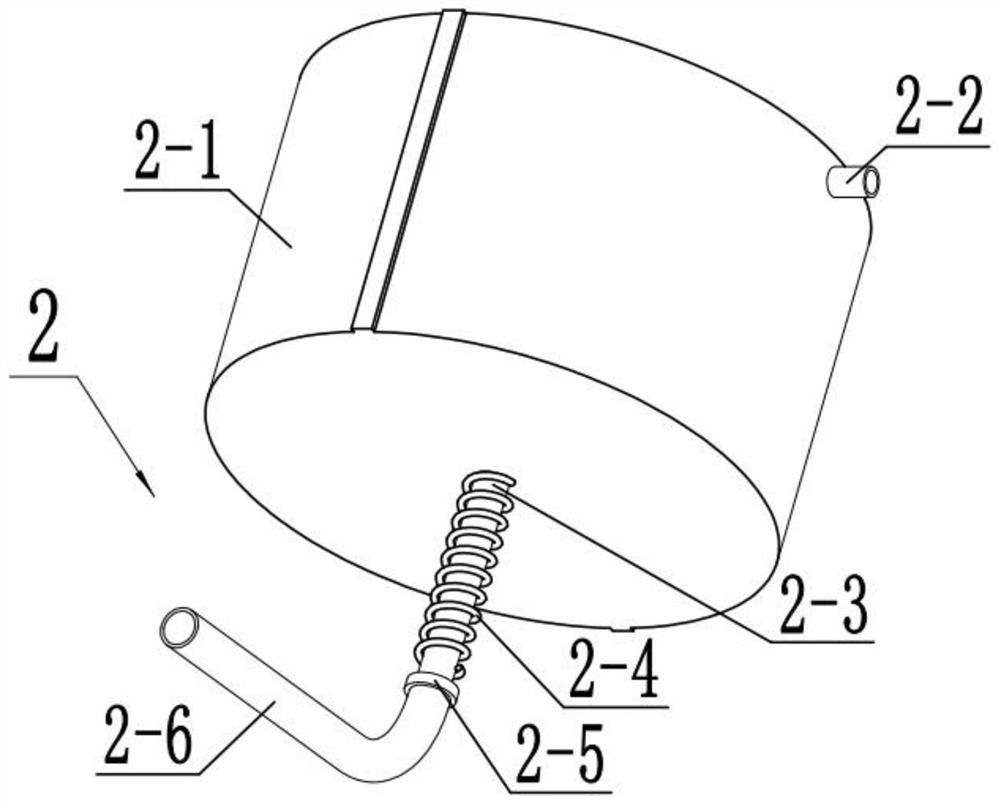

[0042] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the second embodiment, the iron and steel smelting device 2 includes a smelting chamber 2-1, an air intake pipe 2-2, a telescopic empty pipe 2-3, a spring I2-4, a limit The plate 2-5 and the liquid outlet pipe 2-6 place the steel in the melting chamber 2-1, and use the electrode arc generated by the electric arc furnace to heat the steel until it is liquefied. There is a key on the melting chamber 2-1, when the key slides After being connected in the keyway, the limit of the melting chamber 2-1 can be realized, so that the melting chamber 2-1 can only slide up and down, so as to realize the removal of the corresponding amount of additives, and the upper part of the melting chamber 2-1 is fixedly connected with the intake pipe 2 -2 and connected, the intake pipe 2-2 is connected with the oxygen generator, and the oxygen is discharged into the melting chamber 2-1 through the intake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com