Fuel gas ignition jet tube and submerged arc furnace utilizing same

A combustion-supporting air pipe and gas technology, applied in the burner, combustion method, combustion type and other directions, can solve the problems of material freezing in the furnace, electricity consumption, longer production cycle, etc., and achieve the effect of speeding up the smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

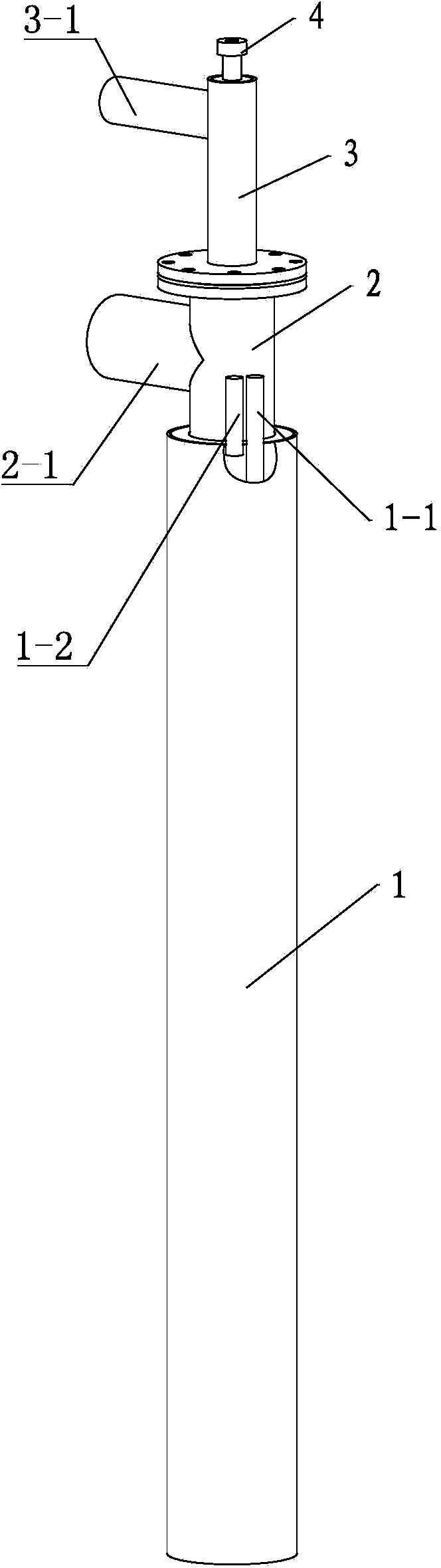

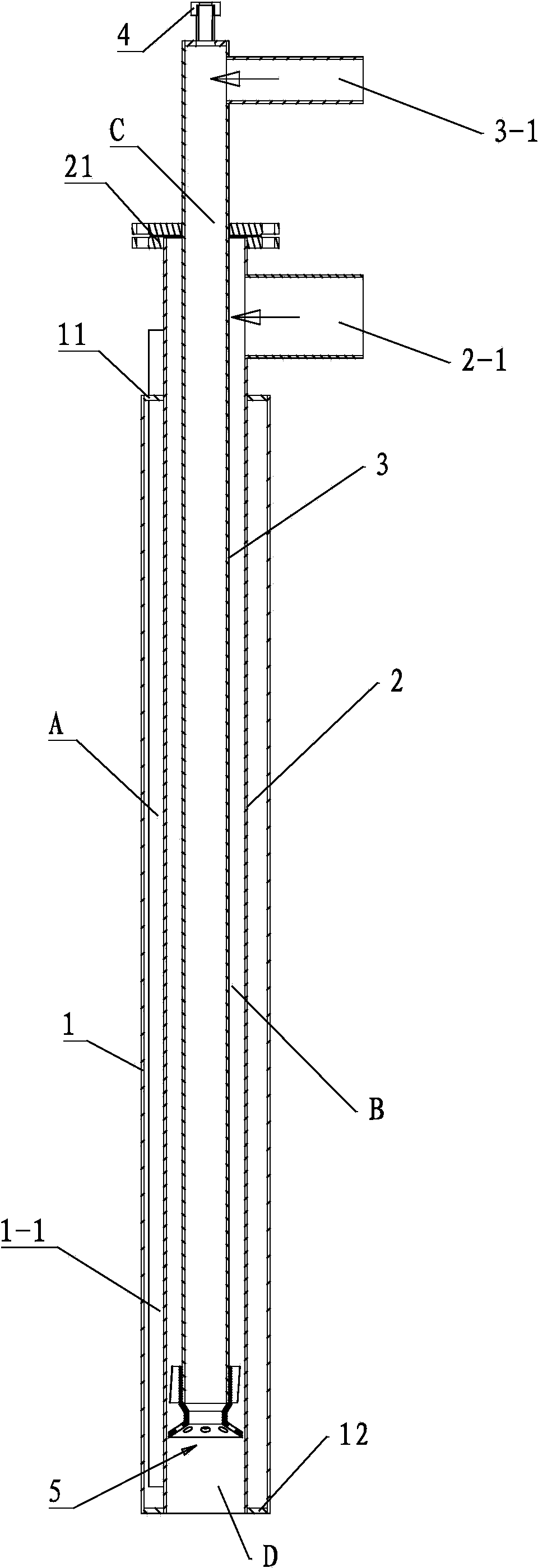

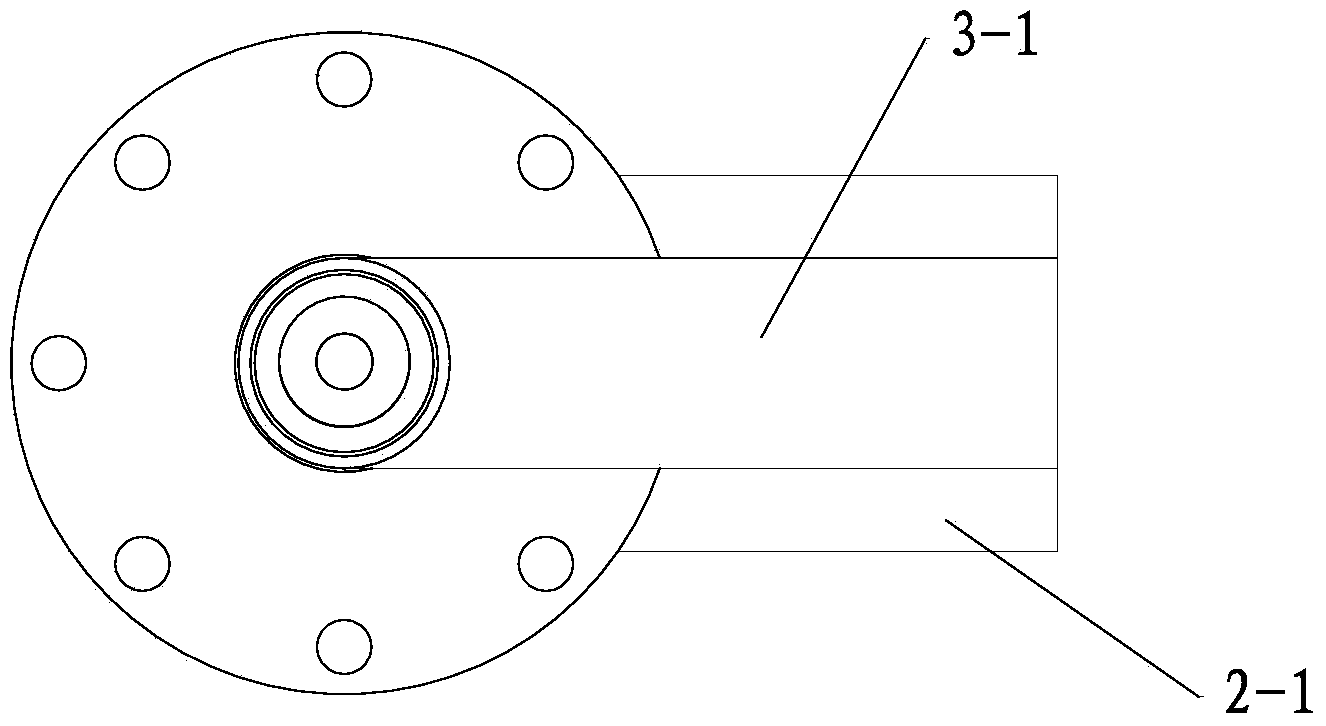

[0027] Such as Figure 1 to Figure 4 As shown, the gas ignition nozzle of this embodiment includes an outer cooling pipe 1, a middle combustion air pipe 2, and an inner gas pipe 3. The top of the outer cooling pipe 1 is provided with a top plate 11, and the bottom is provided with an annular bottom plate 12. A flange plate 21 is arranged on the top of the middle combustion air pipe 2 . Among them, the middle layer combustion air pipe 2 is arranged in the outer layer cooling pipe 1, and the upper end passes through the outer layer cooling pipe 1, the middle layer combustion air pipe 2 is connected with the air connecting pipe 2-1, and the air connecting pipe 2-1 is connected with the external air source, It is used to feed combustion air into the middle combustion air pipe 2. The inner layer gas pipe 3 is set in the middle layer combustion air pipe 2, and the upper end passes through the middle layer combustion air pipe 2, the inner layer gas pipe 3 is connected with the gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com