Medical waste disinfection treatment device

A treatment device and medical waste technology, applied in the field of medical waste disinfection treatment device, can solve the problems of long treatment time, secondary infection and low efficiency of microwave treatment device, and achieve short sterilization time, fast heating speed and high treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

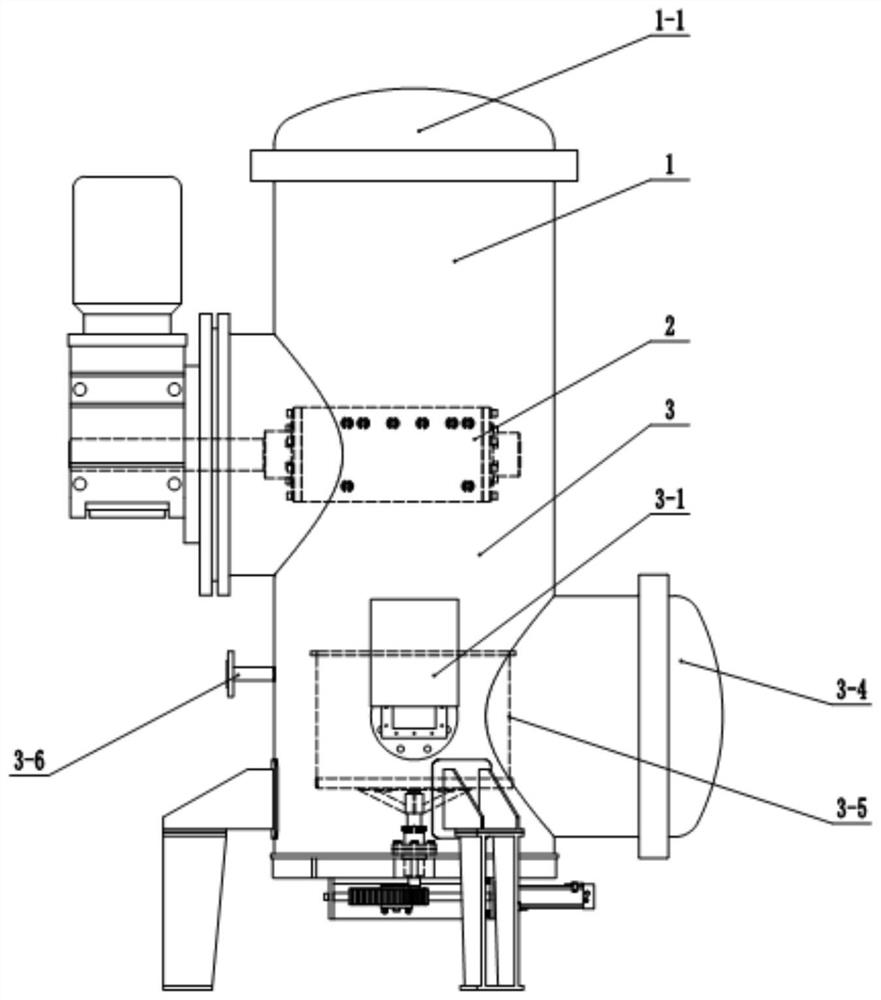

[0034] like figure 1 As shown, this embodiment provides a microwave and high-temperature steam combined disinfection treatment device for medical waste with a specific structure,

[0035] As shown in the figure, it is mainly composed of sterilization chamber 1, crusher 2 and crushing chamber 3, and finally forms a pressure vessel, which can withstand certain positive and negative pressure. In this embodiment, the feed chamber 1 and the sterilization chamber 3 are different chambers in the same chamber, the crusher 2 is located between the feed chamber 1 and the sterilization chamber 3, and the crusher 2 is built in the middle of the chamber, The top chamber of the crusher 2 is the feeding chamber 1, and the bottom chamber is the sterilizing chamber 3, which is also used as the discharging chamber.

[0036] The top of the feeding compartment 1 is provided with a quick-opening feeding door 1-1, and the feeding door 1-1 can be turned over and opened, and can also be opened by tr...

Embodiment 2

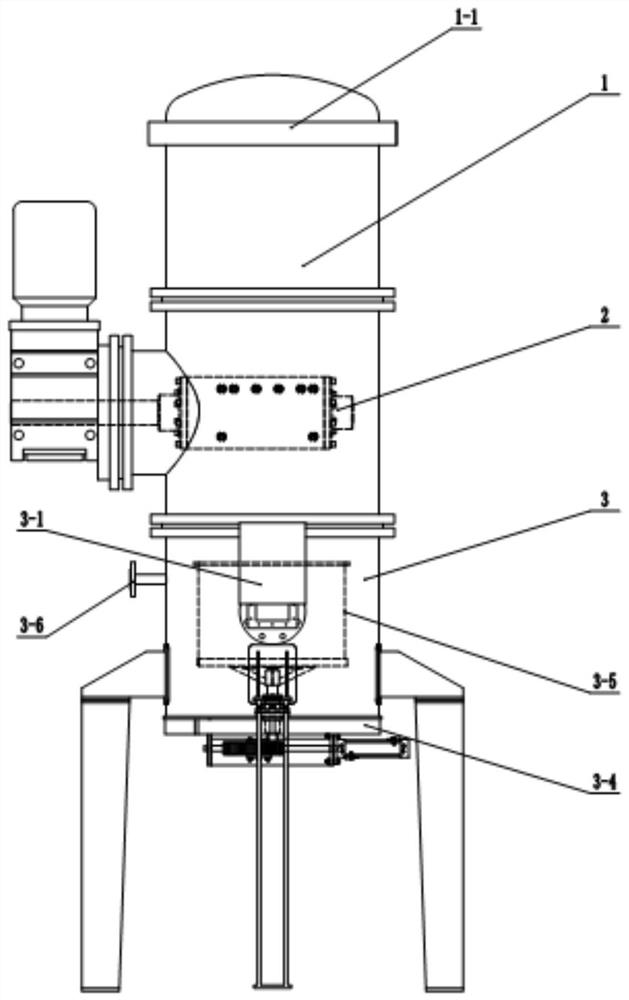

[0042] like figure 2 As shown, this embodiment presents another specific structural form of a device for sterilizing medical waste in combination with microwave and high-temperature steam. The difference from Example 1 is that the feed chamber 1 and the sterilization chamber 3 are designed as different chambers, the crusher 2 is located between the feed chamber 1 and the sterilization chamber 3, and the crusher 2 is built in a separate chamber. Inside, the top is communicated with the feed chamber 1, and the bottom of the chamber is connected with the sterilization chamber 3. The upper, middle and lower compartments are connected and sealed by connecting flanges and bolts. In this embodiment, the discharging door is arranged at the bottom.

Embodiment 3

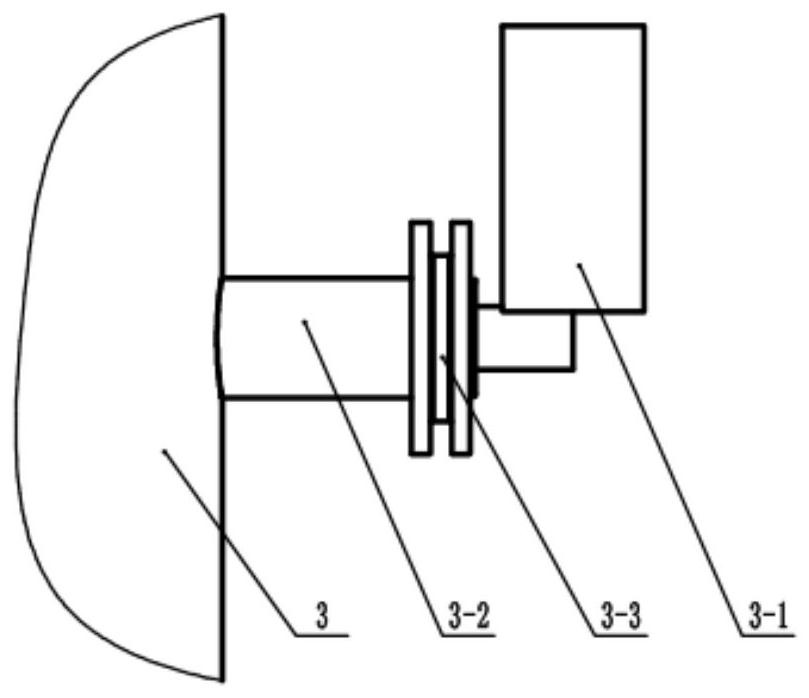

[0044] like Figure 4 As shown, it is the structure when the inner cabin 3-5 is a fixed cabin, the cabin 3-5-1 can be made of metal materials, and the cabin 3-5-1 is provided with a waveguide port 3-5-4 for microwaves to pass through, Entering the cabin, there are stirring blades 3-5-2 in the cabin. The stirring blades 3-5-2 are driven and rotated by the motor, cylinder, oil cylinder and other power mechanisms 3-5-3, and the materials are stirred and turned over to ensure that The material is exposed to microwave and steam to the maximum extent, so as to achieve the purpose of efficient sterilization.

[0045]Under this structure, two structural forms can be adopted, one such as Image 6 As shown, the cabin 3-5-1 and the power mechanism 3-5-3 are connected by a detachable structure, and the separated cabin 3-5-1 can be taken out from the discharge door 3-4 on the side (arrow in the figure). direction), with this structure, the power mechanism 3-5-3 is fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com