Preparation process of activated carbon

A preparation process, activated carbon technology, applied in the field of activated carbon, can solve the problems of waste of resources, process heat, high cost of raw materials, cumbersome process, etc., to achieve the effects of protecting the ecological environment, improving the utilization effect, and increasing revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

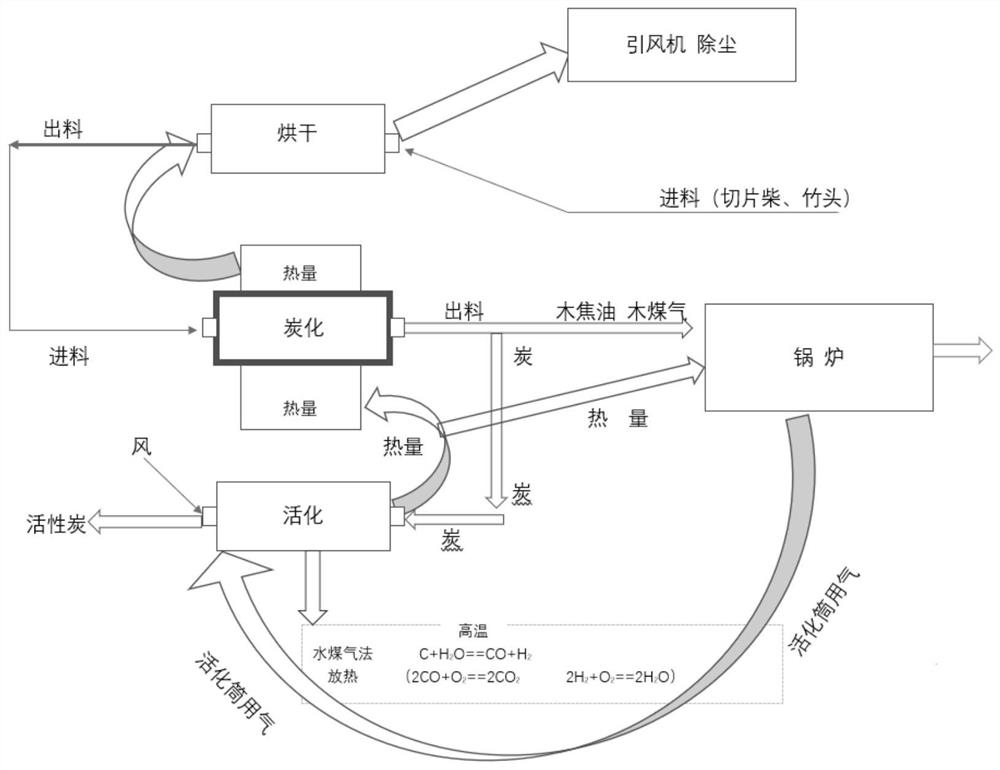

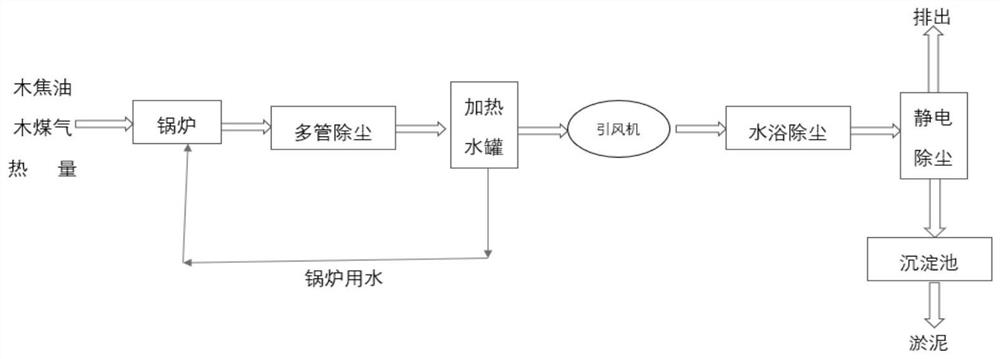

[0039] like figure 1 and figure 2 As shown in a preparation process of activated carbon

[0040] Proceed as follows:

[0041] Step one, material preparation: the mass ratio of 1: 2: 0.4 branches of wood, wood waste wood, bamboo heads are first cut sheet having a thickness of 2cm, length and width is then cut into 3cm 3cm * of a uniform block, after mixing standby;

[0042] Step two, the drying of raw materials: a step of mixing the starting material with a forklift loaded into bin, silo below the conveyor belt using the mixed raw material fed to the drying drum dried at a temperature of 80 ℃ of 2 hours, and then 20min at drying temperature of 105 ℃ conditions, to obtain a moisture content of 8% of the dried material;

[0043] Step three, carbonizing: Step II Dried raw materials feed auger tube carbide 20min preheated at conditions of a temperature of 220 deg.] C, and then carbonized at 600 ℃ 90min under conditions, respectively, the product was collected wood tar, wood gas and car...

Embodiment 2

[0049] like figure 1 and figure 2 As shown in a preparation process of activated carbon

[0050] Proceed as follows:

[0051] Step one, material preparation: the mass ratio of 1: 2: 0.6 branches of wood, wood waste wood, bamboo heads are first cut into a sheet having a thickness of 4cm, and then cut into 5cm * 3cm length and width of a uniform block, after mixing standby;

[0052] Step two, the drying of raw materials: a step of mixing the starting material with a forklift loaded into bin, silo below the conveyor belt using the mixed raw material fed to the drying drum dried at a temperature of 90 ℃ for 3 hours, then 30min at drying temperature is 110 ℃ conditions, to obtain a moisture content of 7% of the dried material;

[0053] Step three, carbonizing: Step II Dried raw materials feed auger tube carbide preheated at conditions of a temperature of 320 ℃ 30min, 120min and then carbonized at a temperature of 660 ℃ condition, wood tar product were collected, wood gas and carbon; wh...

Embodiment 3

[0060] like figure 1 and figure 2 As shown in a preparation process of activated carbon

[0061] Proceed as follows:

[0062] Step one, material preparation: the mass ratio of 1: 2: 0.6 branches wood, wood waste wood, bamboo heads are first cut into a sheet having a thickness of 2.5cm, length and width is then cut into 3.5cm * 3cm uniform block like, mixed use;

[0063] Step two, the drying of raw materials: a step of mixing the starting material with a forklift loaded into bin, silo below the conveyor belt using the mixed raw material fed to the drying cylinder was dried at a temperature of 82 deg.] C for 3 hours, then 22min at drying temperature condition of 106 deg.] C, to obtain a moisture content of 7% of the dried material;

[0064] Step three, carbonizing: Step II Dried raw materials feed auger tube carbide 22min at preheat temperature 250 ℃ conditions, 100min then carbonized at a temperature of 620 ℃ condition, wood tar product were collected, wood gas and carbon; wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com