Smelting method capable of shortening Consteel electric furnace smelting cycle

A technology of electric furnace smelting and smelting methods, applied in smelting, can shorten the smelting field of Consteel electric furnace smelting cycle, can solve the problems of slow slagging, difficult dephosphorization, high FeO content, etc., to reduce operating costs, shorten smelting cycle, improve smelting speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0036] Electric stove: 110t Consteel electric stove.

[0037] Furnace charge structure: the charge is composed of molten iron and steel material (pig iron + scrap steel). The ratio of molten iron and steel material is shown in Table 1.

[0038] Table 1 charge structure

[0039]

[0040]

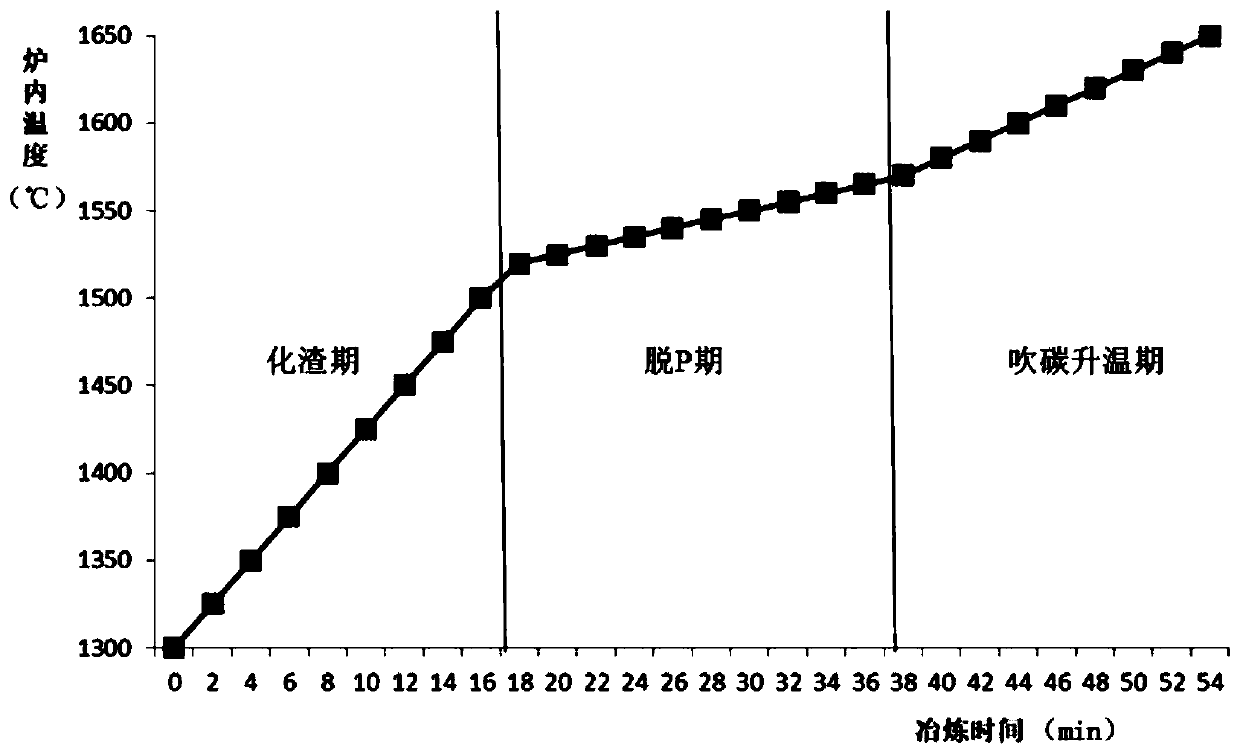

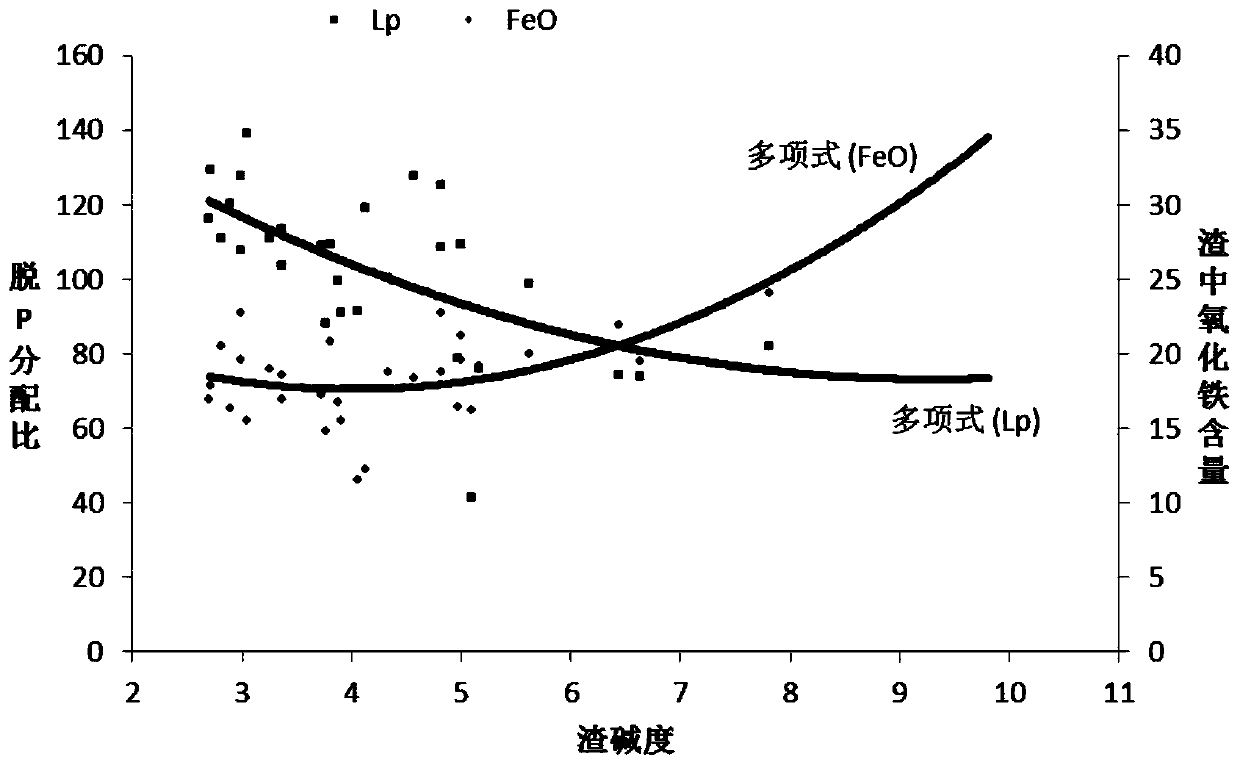

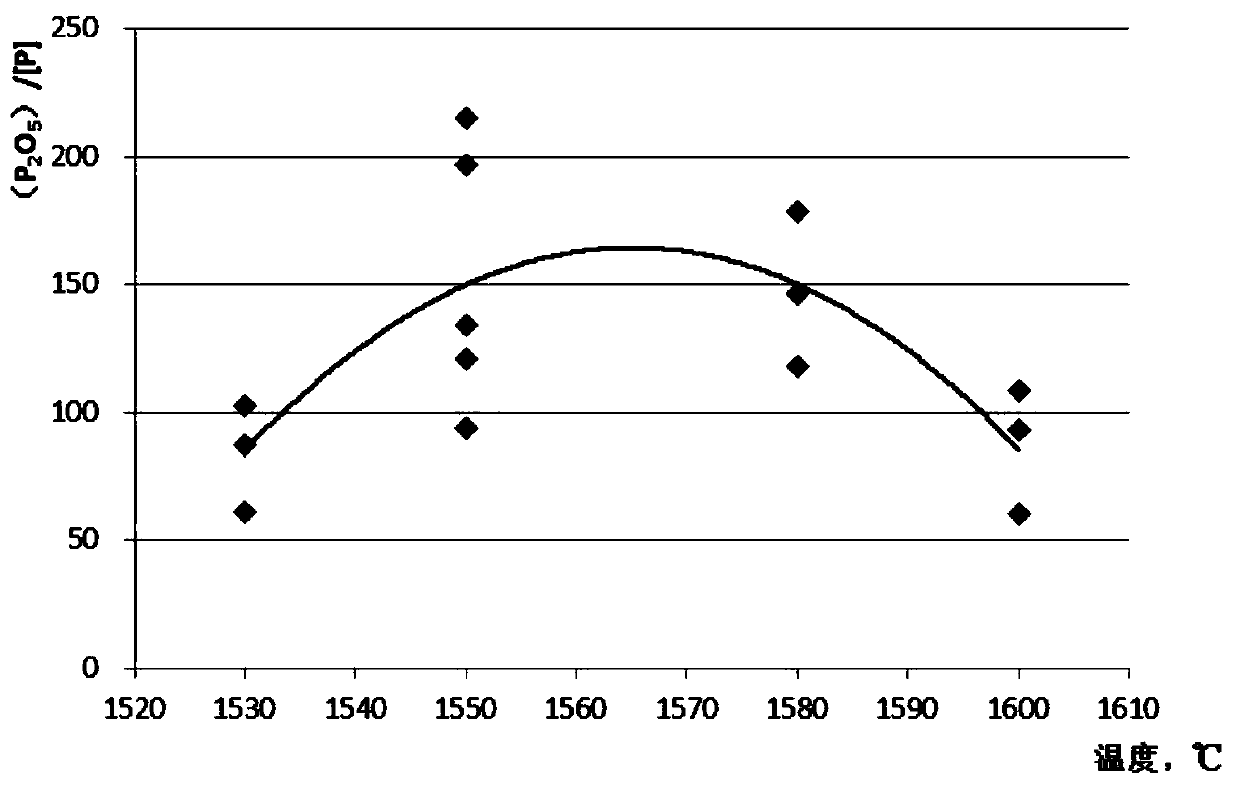

[0041] In order to solve the problem of overoxidation of molten steel at the end of smelting, according to the structure of the Consteel electric furnace charge, the characteristics of feeding, the control of the oxygen lance on the furnace wall, the temperature in the furnace, and the influence of slag conditions on the composition of molten steel, we based on early slag formation, dephosphorization first, and dephosphorization later. Based on the principle of carbon, the entire smelting process is divided into three stages: slag melting period, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com