Adaptive adjustable power wall brushing device and method of underground diaphragm wall joint

A self-adaptive technology for underground diaphragm walls, applied in sheet pile walls, underwater structures, water conservancy projects, etc., can solve the problem that wall scrubbers cannot adapt to scrubbing, joints cannot be cleaned cleanly, and cannot meet the scrubbing capacity of underground diaphragm wall joints, etc. problem, to achieve the effect of improving scrubbing efficiency, increasing scrubbing area, and avoiding residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, further illustrate the present invention. These examples are only for illustrating the present invention and are not intended to limit the scope of the present invention. Now in conjunction with the accompanying drawings, the structural features of the present invention will be described in detail.

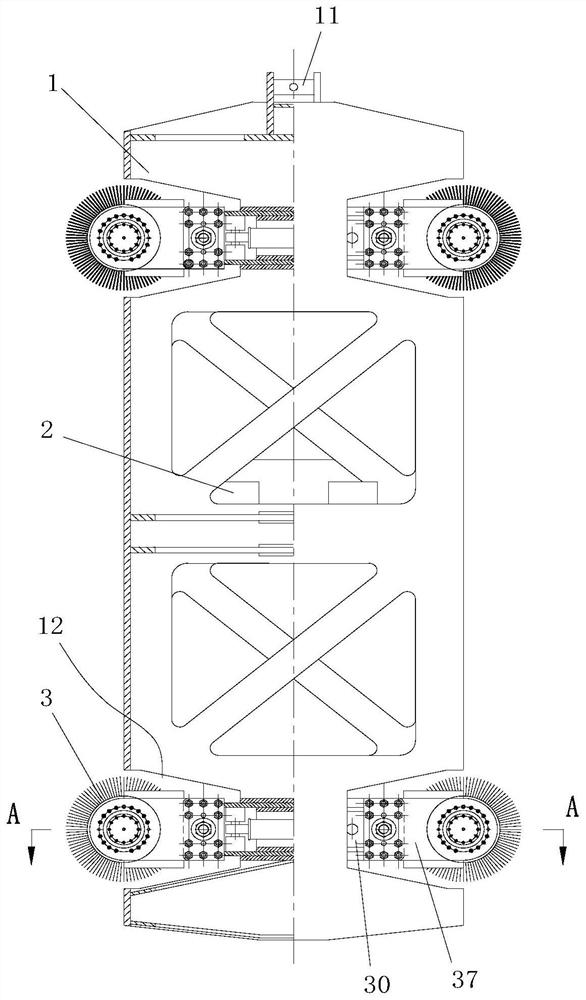

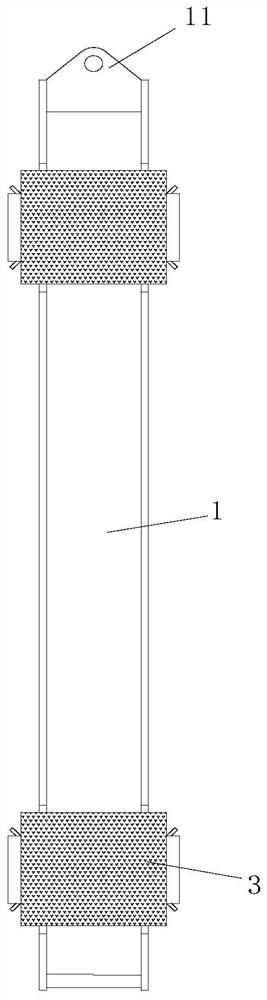

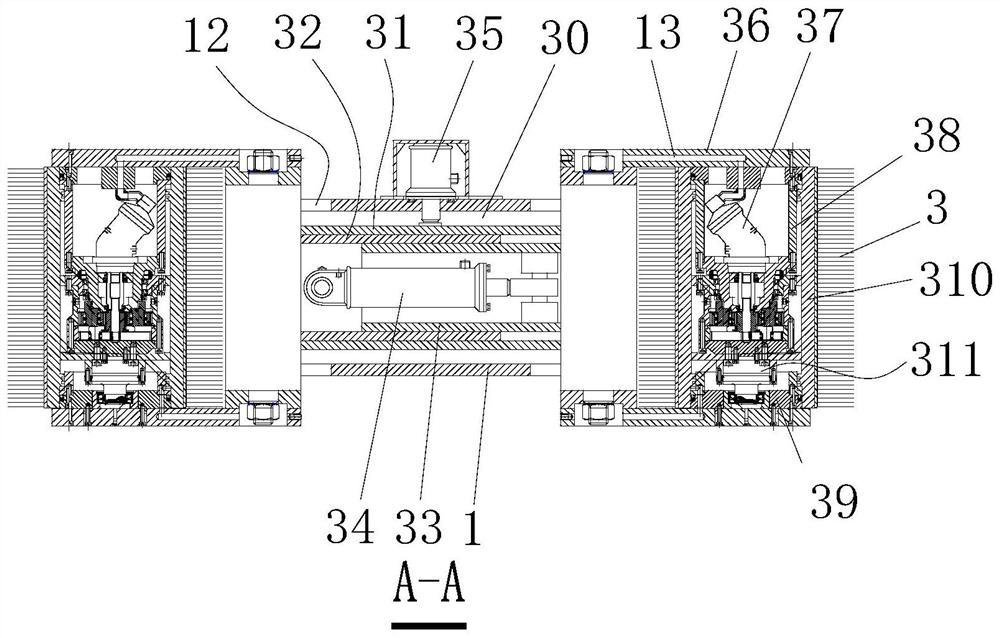

[0021] see Figure 1-3 , an adaptive adjustable power wall brushing device for underground diaphragm wall joints, comprising a box body 1, the top of the box body 1 is fixedly provided with lifting lugs 11, and the lifting lugs 11 are used to install the wall brushing device on a slot milling machine, the box body The two ends of the side of 1 are symmetrically provided with installation grooves 12, and steel wire brush wheels 3 for cleaning continuous wall joints are arranged in the installation grooves 12. The number of steel wire brush wheels 3 is four, and they are evenly distributed on the sides of the box body 1. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com