Thin seam coal mining machine body

A technology for shearer and thin coal seam, which is applied to slitting machinery, earth-moving drilling, mechanical equipment, etc., can solve the problems of poor drum adaptability, high shearer surface height and large span, etc., and achieves guaranteed strength and Effects of stiffness, reduced width dimensions, low deck height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

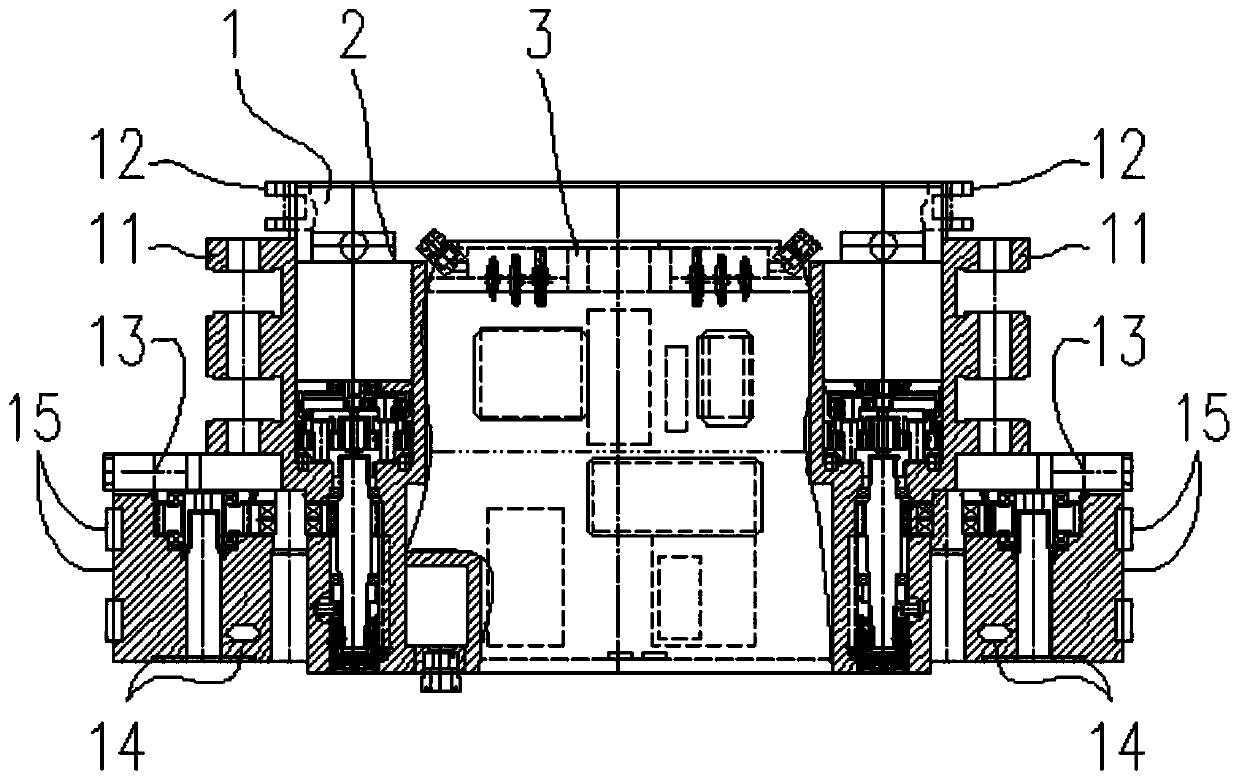

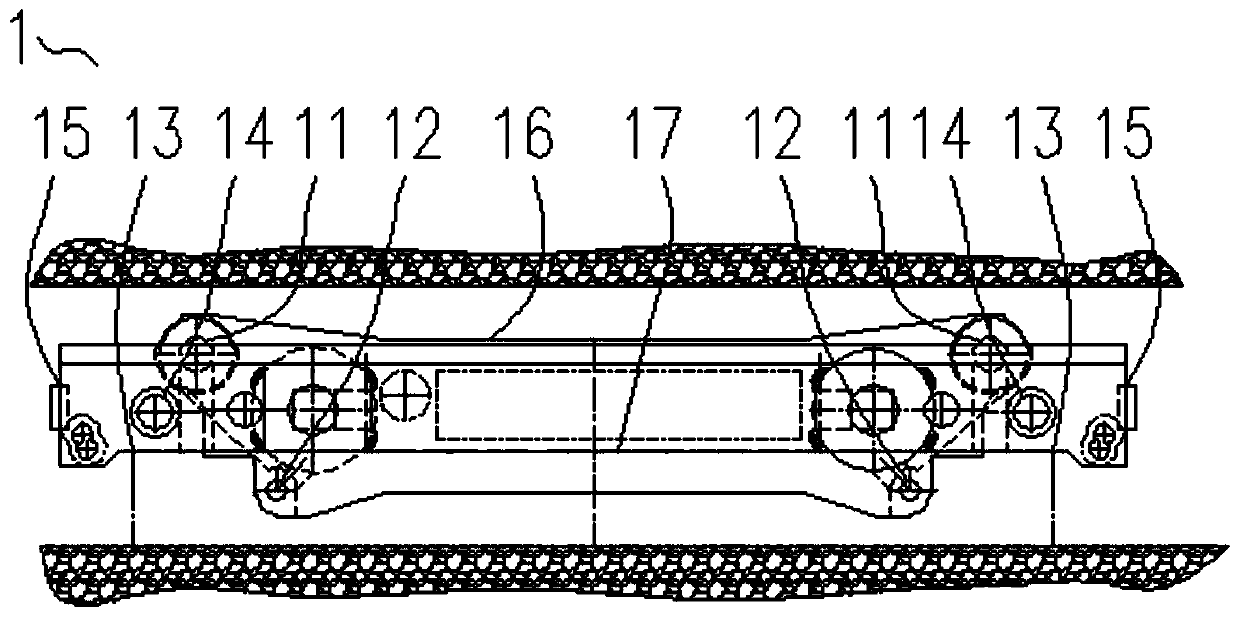

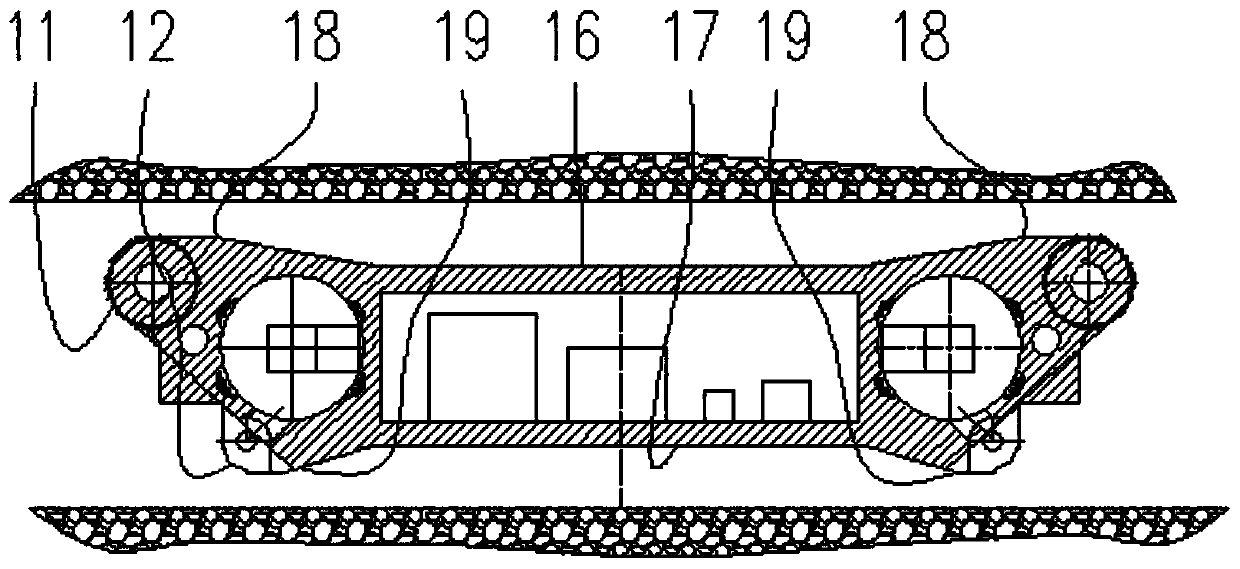

[0036] The invention discloses a thin coal seam shearer fuselage, such as Figure 1-7As shown, it includes a fuselage shell 1, a traction system 2 and an electric control system 3 arranged in the fuselage shell, the electric control system is arranged in the middle, and there are two sets of the traction system, which are respectively placed in the On the left and right sides, the spaces where the electronic control system and the two sets of traction systems are located are independent of each other, so multiple cavities are arranged in the fuselage shell. The traction system is arranged differently in its own space according to the size of each component. Generally speaking, the large and medium-sized components, medium and small-sized components and small-sized components of the traction system are respectively separated by the fuselage shell. The front, middle and rear of the electronic control system are mainly arranged in the front, middle and rear parts of the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com