Pore water pressure gauge and use method thereof

A technology of pore water pressure and water pressure, which is used in the measurement of fluid pressure, measuring devices, instruments, etc., can solve the problems of difficult to meet the measurement accuracy requirements, instrument damage, large range, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

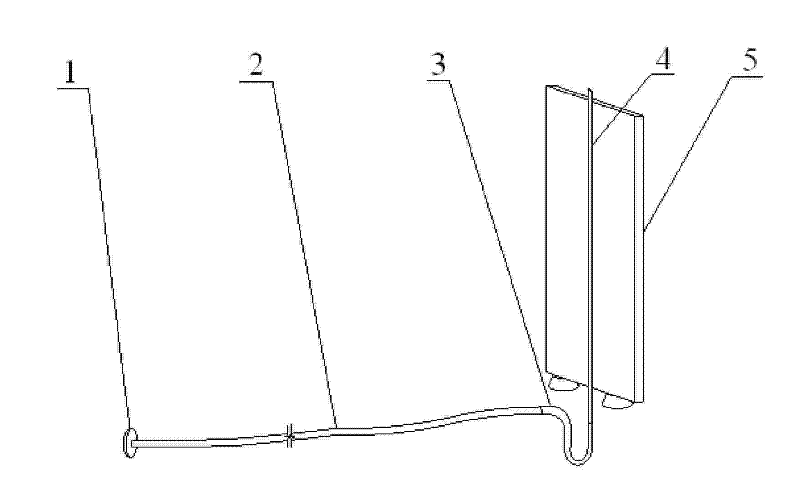

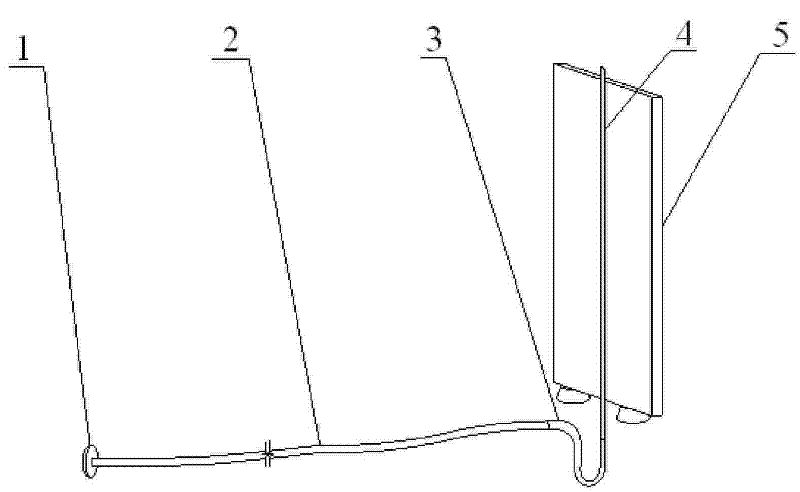

Image

Examples

Embodiment 1

[0040] In the clay foundation pit outburst model test, the model pool has an inner pool and an outer pool, and the inner and outer model pools are both rectangular. The length, width, and height of the outer pool are 2.3m×1.6m×1.0m, and the wall thickness of the outer pool is 260cm. The inner wall and the bottom of the pool are treated with anti-seepage treatment to avoid water seepage and pressure relief. A small sand pool is built inside the outer pool, the distance between the outer wall of the small sand pool and the inner wall of the large model pool is 30cm, the wall thickness of the small sand pool is 140cm, and the inner wall of the small sand pool is also waterproofed. Four steel pipes are pre-embedded in the four corners of the wall of the large model pool, and the bottom of the steel pipes is horizontally laid into the bottom of the small sand tank through joints. The four steel pipes are used for water injection and pressurization.

[0041] A 42-45cm thick sand is ...

Embodiment 2

[0048] Rockfill face dam hydraulic model test, the model pool is rectangular, the length, width and height are 2.3m×1.6m×1.0m, the wall thickness of the pool is 260cm, and the inner wall and the bottom of the pool are treated to prevent seepage and pressure relief. A trapezoidal dam body with a height of 0.8m and an upper and lower bottom of 0.2m and 0.5m is built in the model pool. Both ends of the dam body are connected to the model pool. A permeable stone pore water pressure test point is arranged every 0.1m from top to bottom in the sand and gravel in the dam body, and the water pressure transmission pipeline is laid horizontally and passes through the model pool to connect to the water pressure display board.

[0049] The diameter of the permeable stone at the pore water pressure test end is 30mm, and the thickness is 10mm; the inner diameter of the thin copper tube for the water pressure transmission pipeline is 5mm, and the outer diameter is 8mm. After laying out the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com