Tunnel construction method for passing through weak broken surrounding rock

A technology for crushing surrounding rock and tunnel construction, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems that restrict the safety, rapid development of the urban rail transit industry, large deformation of the support system, and no obvious directionality. Improve the effect of support, strengthen anchoring, and facilitate the effect of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

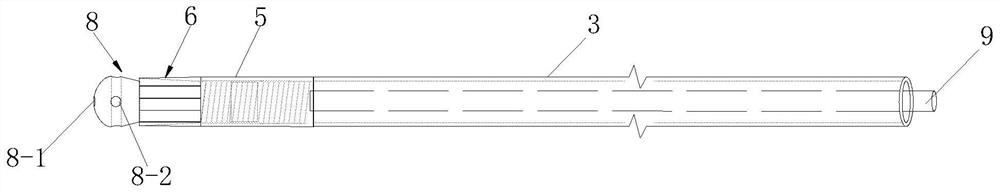

[0052] Such as Figure 1 to Figure 12 A tunnel construction method for passing through weak and broken surrounding rocks is shown, the support structure of the constructed tunnel 4 includes a tunnel initial support structure for the initial support of the constructed tunnel 4 and a tunnel initial support structure arranged inside the tunnel initial support structure. The tunnel secondary lining 17 used for secondary support of the constructed tunnel 4;

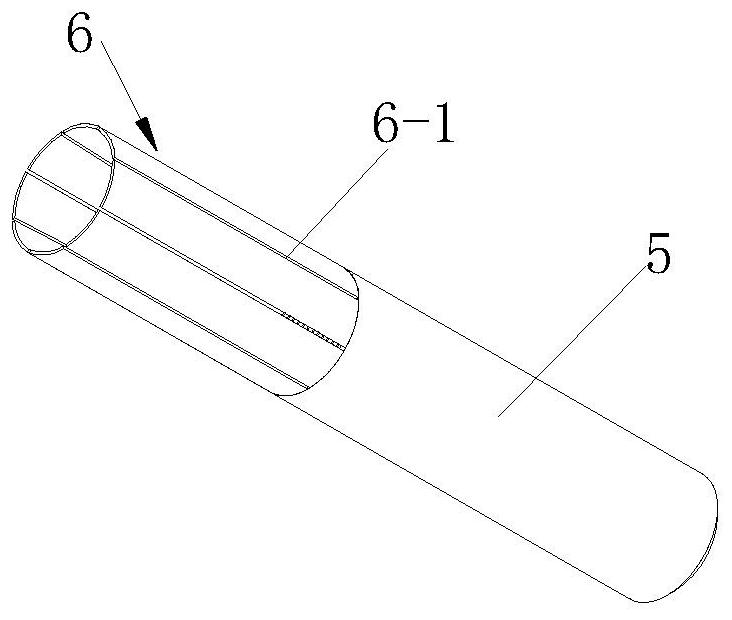

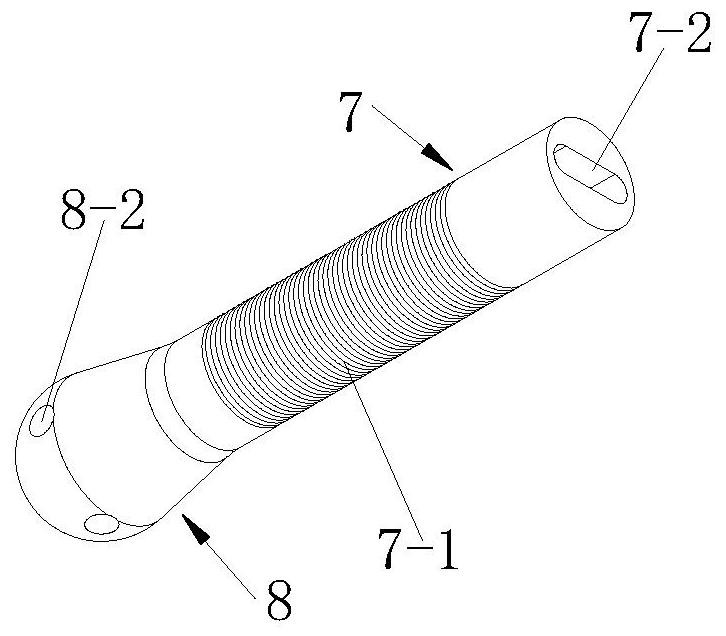

[0053] The initial support structure of the tunnel includes a plurality of tunnel support structures arranged in sequence along the extension direction of the constructed tunnel 4, and the adjacent two tunnel support structures are fixedly connected by longitudinal reinforcement groups before; the tunnel support structure includes The steel arch 1 supporting the inner wall of the tunnel and a plurality of expandable anchoring devices arranged obliquely on the steel arch 1 from inside to outside and arranged along the outline o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com