High-water material filling device suitable for gob-side entry retaining and method of device

A high-water material and filling device technology, which is applied in the direction of filling materials, safety devices, mining devices, etc., can solve the problems of affecting the quality of support, taking a long time, and not being able to fully exert the anchoring effect of bolts, etc., to achieve continuous filling operations and operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below.

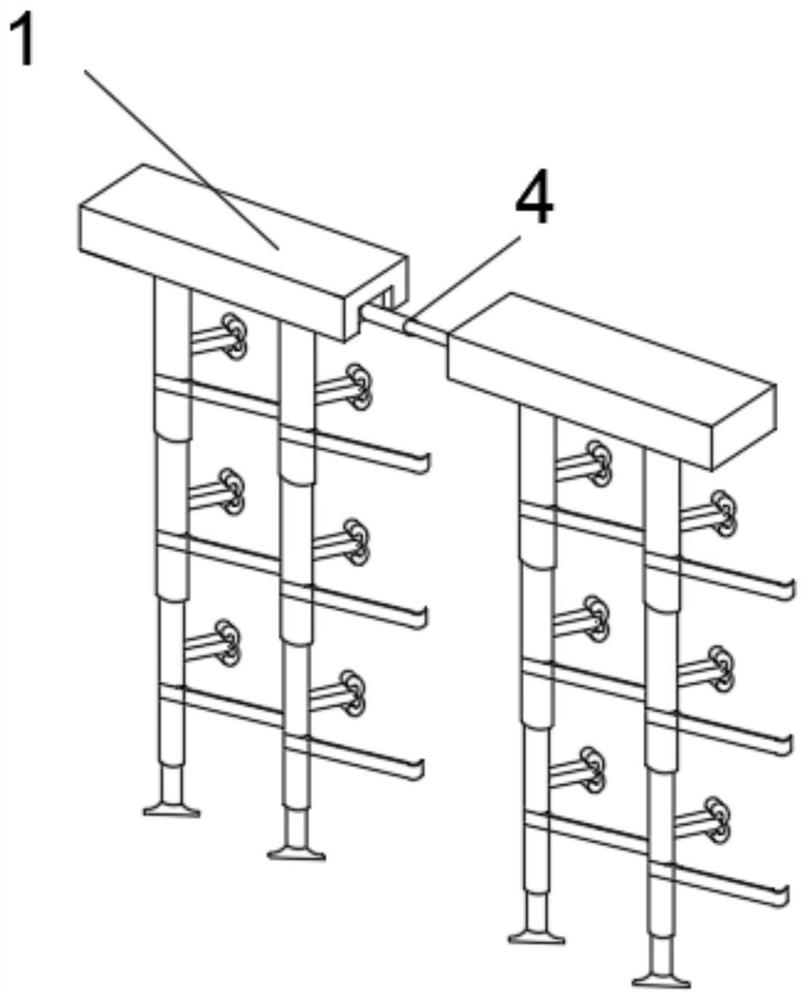

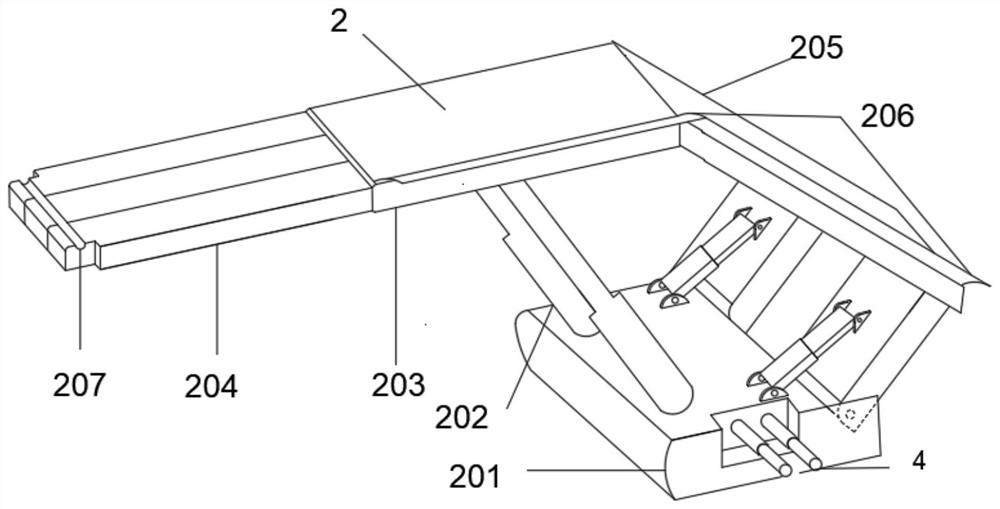

[0030] As shown in the figure, a high-water material filling device suitable for gob-side entry retention includes multiple front hydraulic supports 1 and multiple rear hydraulic supports 2, the number of front hydraulic supports 1 and rear hydraulic supports 2 is the same, and multiple The front hydraulic support 1 and a plurality of rear hydraulic supports 2 are arranged in one-to-one correspondence and arranged side by side, and the adjacent front hydraulic supports 1 and the adjacent rear hydraulic supports 2 are all connected by inter-frame propulsion cylinders 4; each of the The front hydraulic support 1 and each rear hydraulic support 4 are equipped with a combined filling plate 3, and each front hydraulic support 1 and the two combined filling plates 3 on the corresponding rear hydraulic support 2 are arranged oppositely;

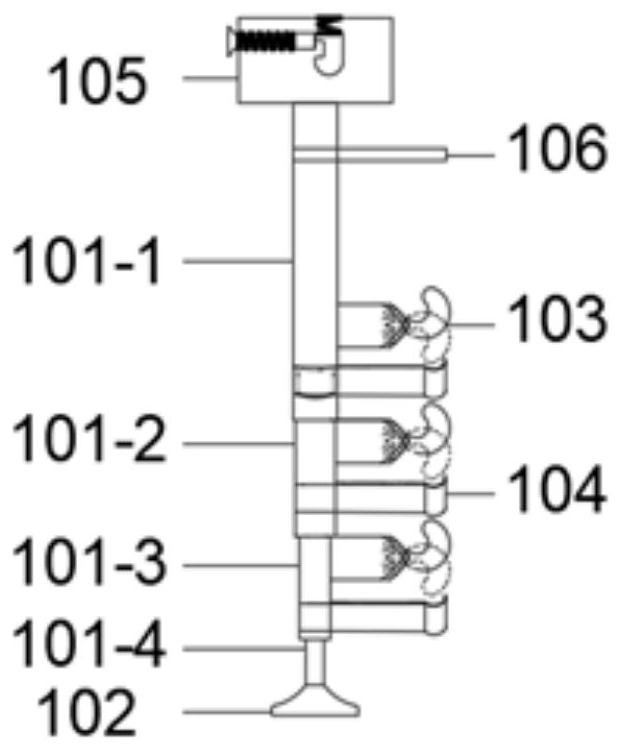

[0031] The front hydraulic support 1 includes a front hydraulic support top beam 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com