Pollen extractor applied to corn genetic breeding

A technology of genetic breeding and corn, applied in the fields of application, botany equipment and methods, plant gene improvement, etc., can solve the problems of scattered pollen, time-consuming and labor-intensive pollen collection, loss, etc., to achieve clear design ideas, strong practicability, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

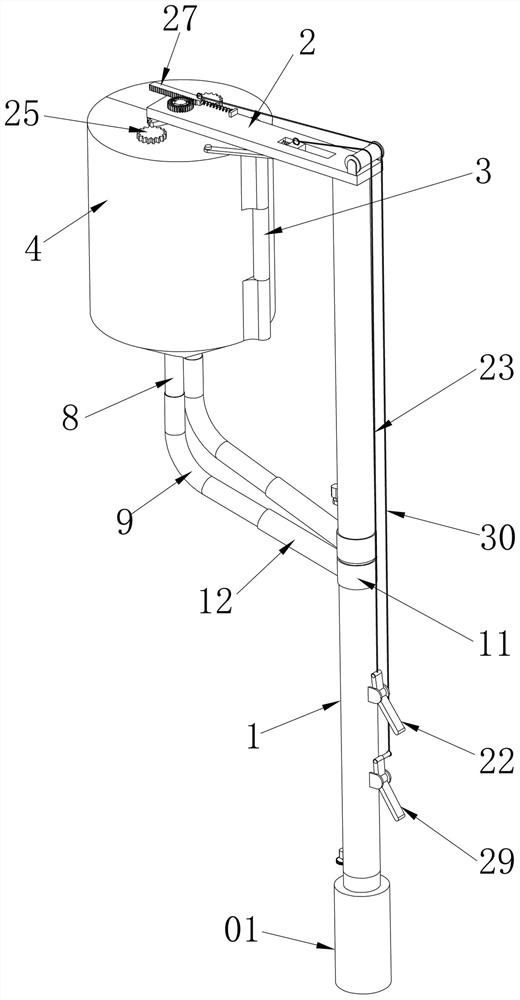

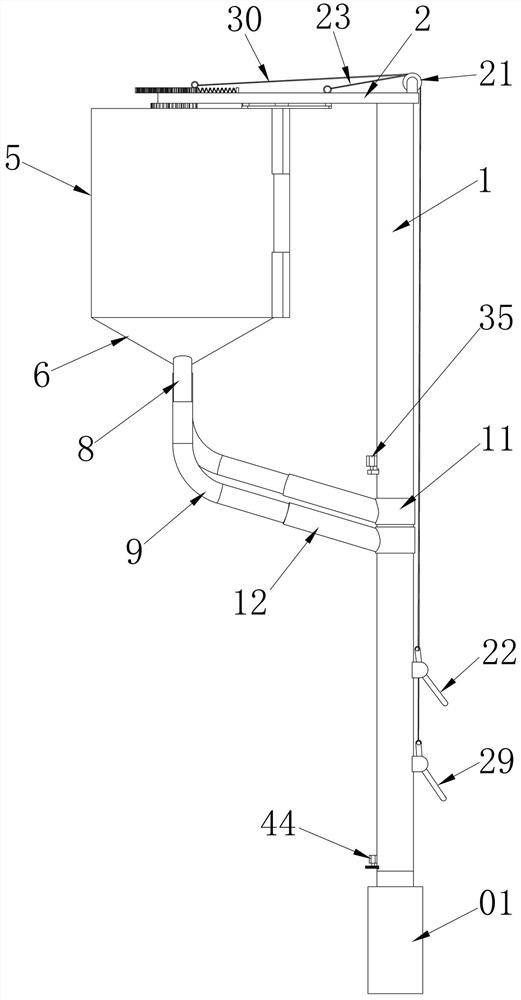

[0036]Embodiment 1. The present invention is a powder extractor used in corn genetic breeding, including an operating rod 1. The operating rod 1 can be a transparent tube, which is convenient for the operator to observe the situation in the operating rod 1. The operation The bottom of the rod 1 is threadedly connected with the collection tube 01, and the collected pollen can enter the collection tube 01 for storage. It is characterized in that a fixed plate 2 is fixedly installed on the top of the operating rod 1, and the fixed plate 2 can be connected with the operating rod by bolts. 1 is connected, the bottom of the fixed plate 2 is fixedly equipped with a vertical fixed rod 3, and two mutually hinged collection tubes 4 are mounted on the fixed rod 3, and the two collection tubes 4 can be mounted on the fixed rod 3, the two collection tubes 4 are composed of a semi-cylinder 5 with an open bottom and a semi-conical tube 6 that is fixedly connected to the bottom of the semi-cyl...

Embodiment 2

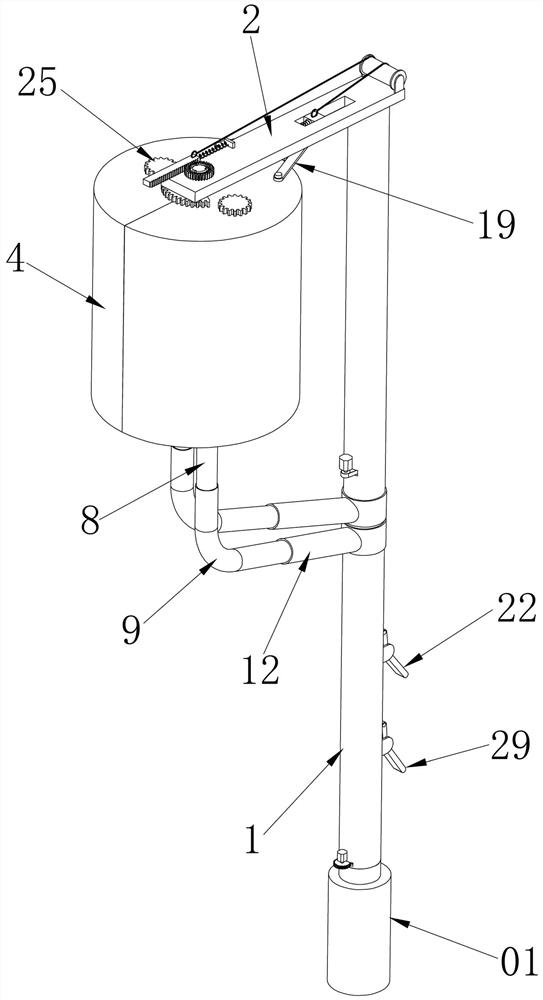

[0037] Embodiment 2, on the basis of Embodiment 1, an opening and closing chute 17 runs through the top of the fixed plate 2 up and down, and an opening and closing slider 18 is slid left and right in the opening and closing chute 17, and the opening and closing The slide block 18 can slide left and right in the opening and closing chute 17, and the tops of the two semi-cylinders 5 are respectively equipped with opening and closing connecting rods 19, and the other ends of the two described opening and closing connecting rods 19 are respectively rotating and equipped with opening and closing connecting rods. On the closing slider 18, when the opening and closing slider 18 slides left and right on the fixed plate 2, the two semi-cylinders 5 can be driven to open or close by two opening and closing connecting rods 19, and the opening and closing slider 18 is connected with the opening and closing An opening and closing extension spring 20 is installed between the chute 17. The op...

Embodiment 3

[0038] Embodiment 3, on the basis of Embodiment 2, a pulley 21 is installed on the right end of the fixed plate 2, and an opening and closing pressure rod 22 is installed on the outer surface of the bottom end of the operating rod 1. The middle part of the rod 22 is rotatably mounted on the operating rod 1, and there is a certain angle between the top and the bottom of the opening and closing pressure rod 22. The opening and closing slider 18 is fixedly connected with an opening and closing pull cord 23, and the opening and closing pull The other end of rope 23 bypasses pulley 21 and is fixed on the top of opening and closing pressure bar 22, presses opening and closing pressure bar 22 during use, and opening and closing pressure bar 22 drives opening and closing slide block 18 to slide rightward by opening and closing pull cord 23, Thereby two described collecting tubes 4 are opened, and when the opening and closing pressure rod 22 is unclamped, the opening and closing slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com