Replaceable tire mold structure

A replaceable, tire membrane technology, used in auxiliary devices, vehicle parts, auxiliary welding equipment, etc., can solve the problem of non-replaceable tire membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

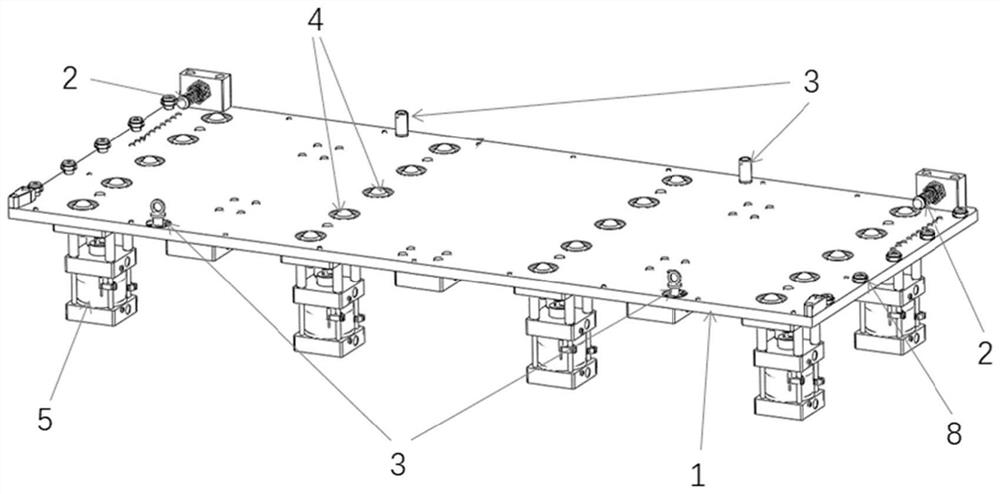

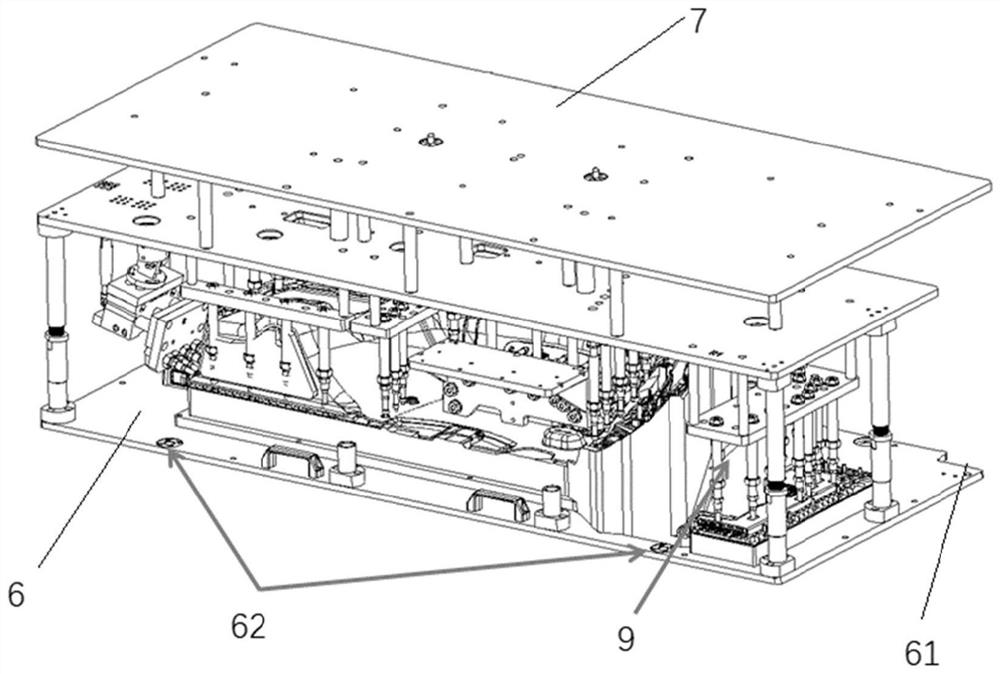

[0030] In the present invention, the replaceable tire membrane structure includes tire mold bottom plate 1, cylinder 5 and welding module, see figure 1 and figure 2 .

[0031] A thrust unit 2, a positioning unit 3, a sliding unit 4, and a guide unit 8 are arranged on the base plate 1 of the tire mold, see figure 1 .

[0032] During specific implementation, the thrust unit 2 is a thrust block arranged vertically to realize the lateral thrust limit when the welding module is disassembled and installed, and the thrust block can abut against the limit gap 61 to realize lateral Thrust limit.

[0033] During specific implementation, the positioning unit 3 is a positioning pin, and the positioning pin is arranged on both sides of the tire mold base plate 1 , and the positioning pin matches the positioning hole 62 .

[0034] During specific implementation, the guide unit 8 is a guide bearing, and the axis of the guide bearing is in the vertical direction. When the welding module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com