Method for detecting parallelism of movement of heavy vertical lathe vertical tool rest to working table

A technology of vertical tool post and vertical lathe, applied in the direction of manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., it can solve problems such as difficult operation, error, deflection and deformation, and achieve high efficiency, high precision and simple operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

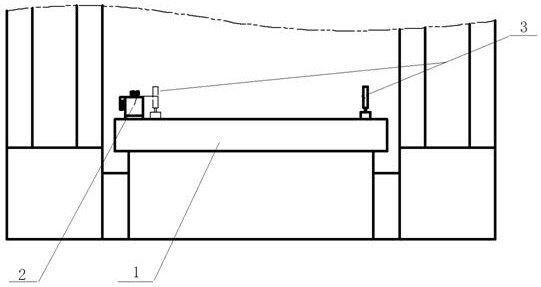

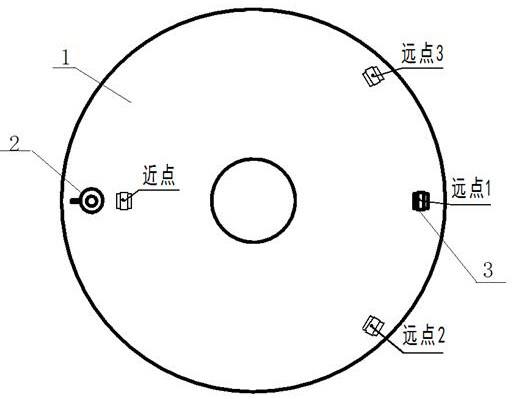

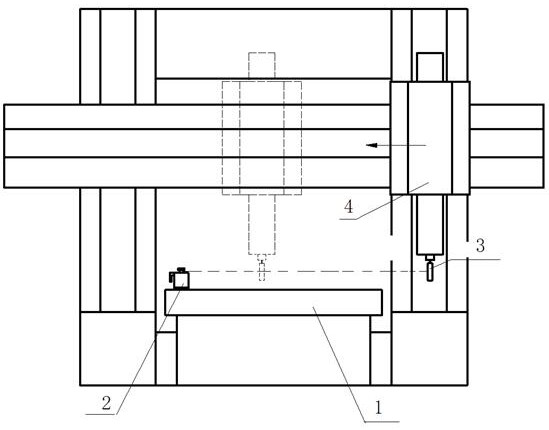

[0014] Such as Figure 1-3 As shown, a method for detecting the parallelism of the vertical tool rest movement of a heavy-duty vertical lathe to the worktable surface is to place the laser transmitter 2 of the laser geometry measuring instrument at a position on the workbench 1 that can scan the area of the vertical tool rest 4, and use The laser receiver 3 of the laser geometry measuring instrument is set to zero at the near point and zero at the far point. Adjust the rotating laser surface of the laser transmitter 2 to be parallel to the surface of the workbench 1 to establish a reference plane. In order to establish a reference plane The accuracy is adjusted by the laser receiver 3 again at the three far points, the laser receiver 3 is placed on the vertical knife holder 4, and the receiver 3 is adjusted to receive the range of the rotating laser plane, and the vertical knife is started. Frame 4 is used for detection, and the laser geometry measuring instrument is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com